This post contains a detailed look at a typical P&ID arrangement for Pig Launchers / Receivers and the design considerations that go into it. Pig launchers and receivers are commonly used in the upstream oil and gas industry for the periodic cleaning of pipelines carrying crude oil, natural gas, and water from oil wells. A pig is a bullet-shaped object which fits the pipeline from the inside. The pig launcher launches the pig into the pipeline and the upstream pressure pushes the pig to the other end of the pipeline where it is received by the pig launcher.

Hence generally the arrangements for pig launchers and receivers are essentially the same, except for the difference between the 'Kicker line' position for launchers and receivers.

Table of content:

Typical P&ID arrangement for Pipeline Pigs

Guidelines to prepare a P&ID for pig launchers and receivers

Typical P&ID arrangement for Pipeline Pigs

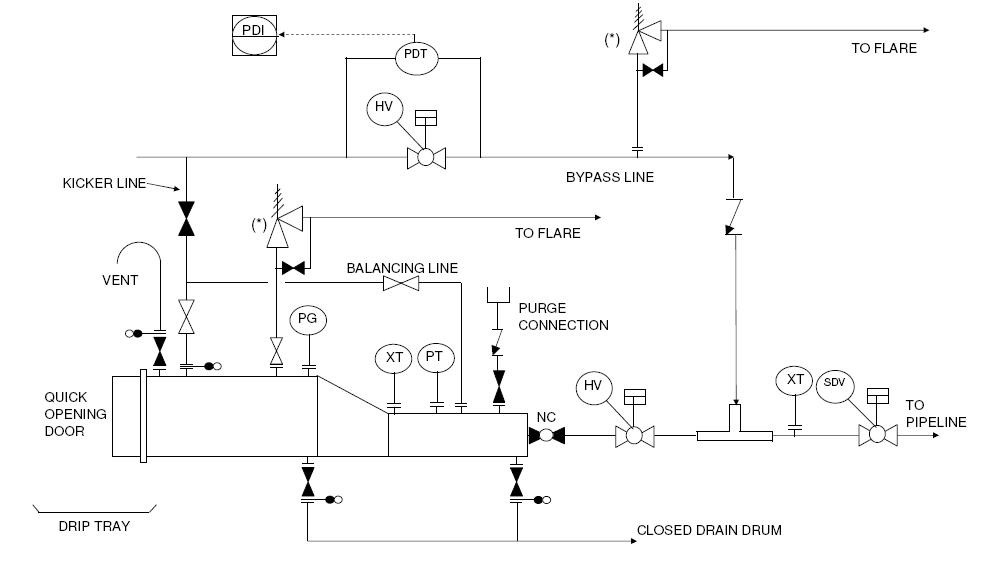

The sample drawing presents this general arrangement common to pig launchers and receivers.

Guidelines to prepare a P&ID for pig launchers and receivers

Selection of equipment

Proper equipment symbol for pig launcher (vertical or horizontal) should be selected first of all, as shown in the presented drawing. This should be selected from the list of equipment symbols on the legend sheets of a particular project.

Barrels

The major and minor barrels of the pig trap should be indicated as shown in the sample drawing. Minor barrel size is equal to the pipeline size and the major barrel size is slightly larger.

Nozzles

All the nozzles on the pig launcher should then be correctly represented with size and flanges. This includes door on the launcher, pig outlet to pipeline, kicker line, balancing line, PSV connection, purge, vent, drain, and instrument nozzles, as shown in the sample drawing presented here. Typical instrumentation on the pig launcher would be pressure gauges and transmitters and pig indicators to know if the pig has been launched (or arrived in the case of pig receivers).

Connecting lines

Different lines connected to the pig launcher are the next to be drawn up. Line number, material class, size etc. is to be correctly assigned to each of the lines.

Kicker line is used to pressurize the upstream side of pig so it can be launched. In case of receiver, kicker line provides an outlet for fluids arriving in the pig trap. Normally when pigging is not being performed, kicker line is closed using normally closed valve.

The Balancing line connecting the kicker line to minor barrel of the pig launcher, helps lower the pressure differential so that sudden shooting of the pig will not damage downstream automatic valves.

A bypass line of the pig launcher is the normal route for the fluids when pigging is not taking place. This section upstream to the shutdown valve at beginning of pipeline can be protected against overpressure as indicated in the sample drawing.

Hand operated valve

The hand operated valve (HV) on the bypass line is used to create a pressure differential for launching the pig (also for receiving the pig). A pressure differential indicator (PDI) has to be available to the HV operator to monitor the pressure differential.

On the outlet of the pig launcher, another hand operated automatic valve is provided to open up the launcher upon pressurization.

The pig launcher (and receiver) are also protected against overpressure with a PSV which discharges to flare. A typical representation of PSVs can be referred to in another article.

Isolation valves, spectacle blinds and spacers

Isolation valves, spectacle blinds, spacers etc. to be used for maintenance should be drawn up next, on various lines to and from the pig trap. The spectacle blinds, spacers etc. are usually connected right next to the isolation valves and equipment nozzles, as indicated in the sample drawing presented here.

Vents & Drains

Drains should be provided either on major or minor barrel or on both for complete draining of the pig trap after the pig is launched or received. Sample drawing has indicated drains on both the barrels. These drains are connected to the closed drain system.

Vents to flare and to atmosphere are required on pig launchers. Venting to flare for depressurization of the pig launcher can be achieved using bypass on the relief valve. For maintenance, when pig is not in operation it can be vented to atmosphere.

Utility connection

A utility connection is required to purge the pig launcher / receiver after the pigging is done and the pig trap is depressurized and drained. A nitrogen connection should normally be provided as indicated in the sample drawing.

Most of the guidelines mentioned for pig launchers also hold good for pig receivers.

All the guidelines given here are very general and may be modified as per specific requirements of any particular project.