Usually crude oil extracted from geological sources is accompanied by hydrogen sulphide gas (H2S). This H2S is separated from rest of the oil at the atmospheric distillation unit along with lighter hydrocarbons and collectively termed as ‘sour gas’. H2S is separated from hydrocarbons at the amine treatment unit and H2S rich gas flow is sent to sulphur recovery unit (SRU) for extracting elemental sulphur from H2S gas.

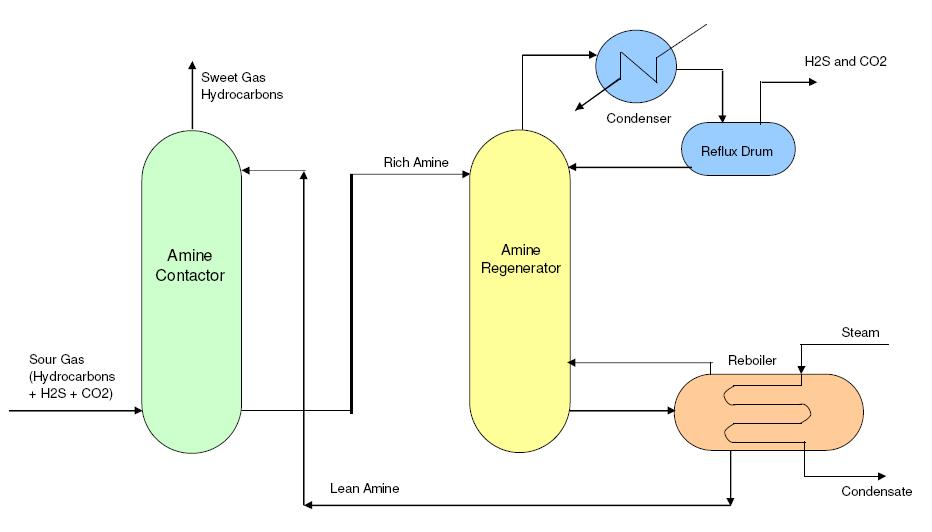

Amine treatment unit uses Methyl Di Ethanol Amine or MDEA to remove H2S and CO2 gases from other lighter hydrocarbon gases. An amine treatment unit involves two stages. First stage is an amine contactor where gases are bought in contact with amine and H2S and CO2 are absorbed in the liquid phase. Second stage is an amine regenerator where H2S and CO2 are stripped away from the liquid phase to regenerate the lean amine solution to be recirculated to the amine contactor column.

Amine contactor is essentially an absorption column. The lean amine solution flows from top to the bottom of absorption column. The sour gas flows from bottom of the column to the top. H2S and CO2 are preferentially absorbed in the amine solution and sweet hydrocarbon gases are taken out from the column overhead. Amine solution rich in H2S and CO2 is taken out from the bottom of absorption column and taken to amine surge drum.

The hydrocarbons condensed to liquid phase in the amine contactor flow along with the amine solution to amine surge drum which is a 3-phase separator and hydrocarbon condensate is separated from amine solution using a weir.

Rich amine solution separated in the amine surge drum is then taken to the amine regenerator columns which is essentially a stripper column. The rich amine solution in introduced at the top of the column. This amine solution is taken out from the column bottom and fed to the amine reboiler which utilizes steam to boil off H2S and CO2 from the amine solution. These vapors are introduced at the column bottom they flow in contact with the rich amine solution to the top of the regenerator column and are taken out from the column overhead. The vapors from column overhead are fed to a condenser to extract any entrained amine which is recycled to the column top. In this way, lean amine is regenerated at the bottom reboiler of the regenerating column and recycled to the amine contactor column. The acid gas (H2S and CO2) is removed from regenerator overhead and taken to the sulphur recovery unit (SRU).