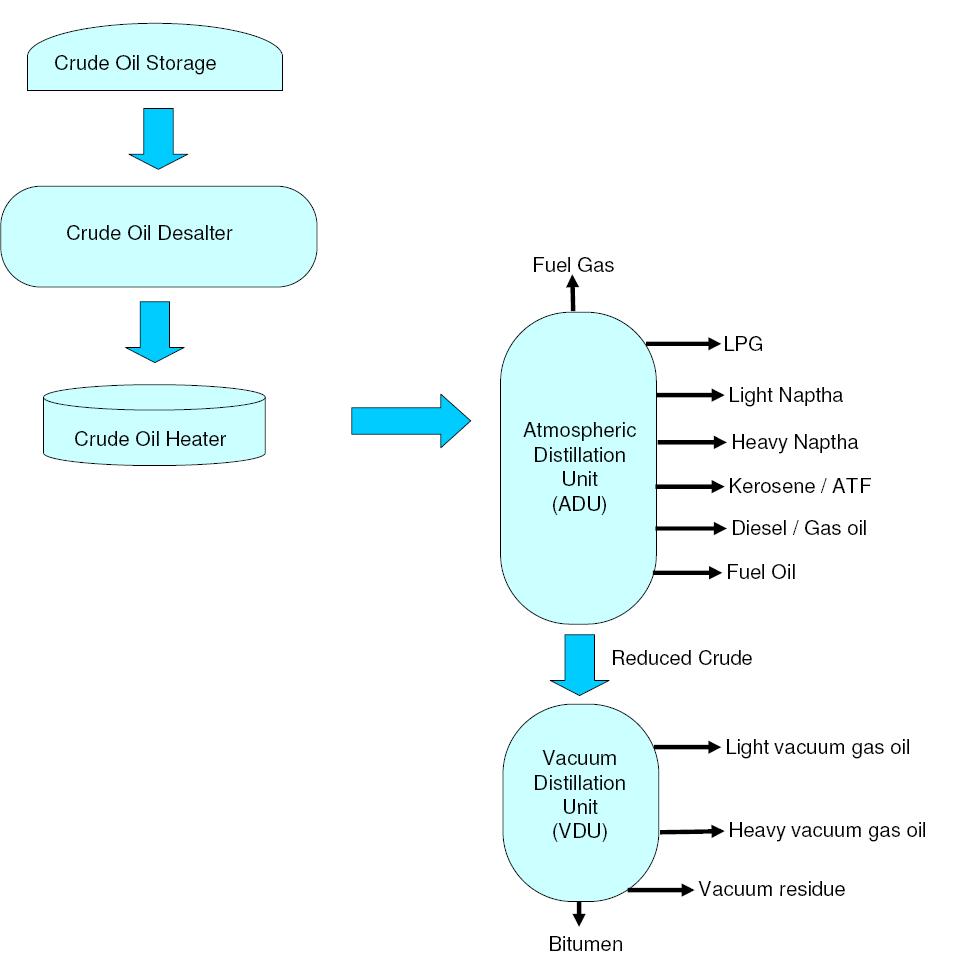

Crude Oil Storage

Generally crude oil is extracted from the geological sources then stored in the crude form until it is shipped to a refining facility where it is converted to usable end-products. Once in the refinery, the crude oil has to be stored until processing capacity is available to convert it to gasoline and other products.

These storage tanks may also serve another function of separating BS&W (Bituminous Sediment and Water) content from the oil by virtue of gravitational settling. The separation depends on how long the oil is store in tanks also known as residence time.

Usually crude oil come along with some sulphur content. Hence, crude oil storage tanks have to be designed with special materials to prevent corrosion resulting from sulphur content.

Crude Oil Desalters

Generally, crude oil contains salt, predominantly chlorides. Chloride salts can combine with water to form hydrochloric acid in atmospheric distillation unit overhead systems causing significant equipment damage and processing upsets. Also, salt deposition on heat exchanger surface, reduces the efficiency of those exchangers and increases maintenance costs.

The crude oil is generally heated to around 60-100 0C before sending it to desalter vessel. Desalters use fresh water to wash away the salts from crude oil forming and emulsion. This water containing salts is then removed using high voltage electrostatic fields, which enhances oil - water separation. The effect of electrostatic field is to increase the water droplet size, so that water can settle down by gravitational effect.

Crude Oil Heater

Following the desalter, the crude oil is further heated by exchangeing heat with distillation products, internal recycle streams and tower bottoms liquid. Finally fuel-fired furnace (fired heater) is used to heat this crude oil stream to a temperature of about 400 °C and routed into the bottom of the Atmospheric Distillation Unit (ADU) or Crude Distillation Unit (CDU).

Atmospheric Distillation Unit or Crude Distillation Unit (CDU)

The atmospheric distillation unit exploits the difference between boiling points of various components of crude oil to separate them from each other. Operation of a distillation column causes highest concentration of lower boiling, highly volatile hydrocarbons at the top of distillation column and the higher boiling, less volatile hydrocarbons are separated from the bottom of the column. There is a temperature gradient along the height of the column to cause this separation. The bottom of a distillation column is continuously heated using a reboiler and top of a distillation column is cooled using overhead condenser. This cause the temperatures to drop along the height of the column. At every stage (tray) of the columns the hydrocarbons approach vapor-liquid equilibrium, allowing the lighter hydrocarbon gases to escape to top while the heavier hydrocarbons trickle down to column bottom. The operating pressure also drops from bottom to top of the distillation column. The range of operating pressure is close to atmospheric pressure and hence the name.

This results in higher concentrations of specific groups of hydrocarbons at different stages of the distillation column. So, different cuts of hydrocarbons can be drawn off from different stages of the distillation column.

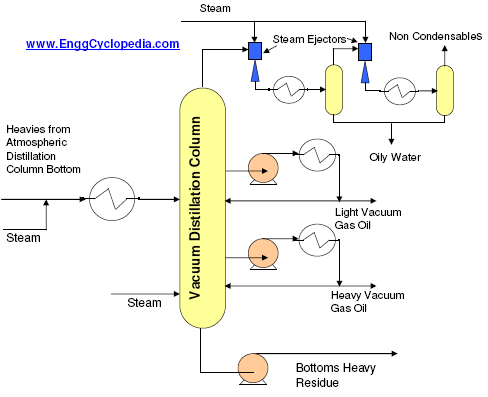

Vacuum Distillation Unit (VDU)

The heavy hydrocarbons which cannot be separated in the CDU are sent to the vacuum distillation unit (VDU) for further separation. The operating principle of vacuum distillation unit is same as that of the atmospheric distillation unit, which allows different composition or grade of hydrocarbons to be separated at different stages or trays of the distillation column. The main difference between these two columns is the operating pressure. Vacuum distillation unit operates at pressures as low as 10-20 mm of Hg. (CDU operates at atmospheric pressure 760 mm of Hg)

Products of crude oil refining

The objective of crude oil refining is to separate different hydrocarbon components from the crude oil mixture, so that they can be used for a variety of different applications as - crude oil products. For example -

- Fuel gas

- LPG or Liquified Petroleum Gas

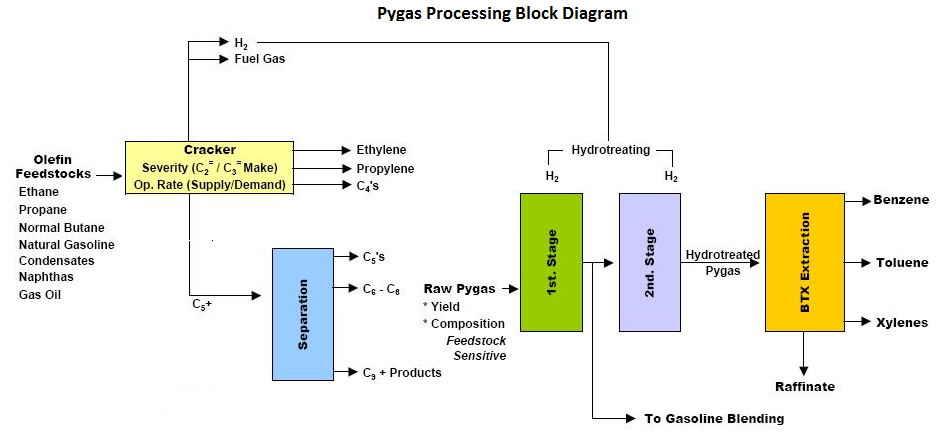

- Petrol / gasoline

- Diesel

- Kerosene

- Fuel oil

- Bitumen

- Sulphur