Rupture disc serves as crucial component in safeguarding pressure containing systems such as pressure vessels, storage tanks, reactors etc. Rupture discs are non reclosing devices. These devices are designed to burst or rupture at predetermined set pressure. By bursting or rupturing these devices relieve excess pressure and prevent system from catastrophic failure. This post explores rupture discs in detail.

Table of content:

1. What is rupture disc?

2. Combination of rupture disc and pressure relief valve

3. Advantages of rupture discs

4. Applications

5. Rupture disc sizing

What is rupture disc?

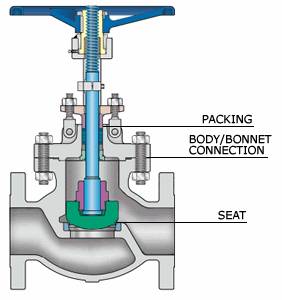

A rupture disc, also known as a bursting disc or burst diaphragm, is a non-resealing, sacrificial, pressure relief device used for protection of a pressure vessel from potential damage from overpressure or vacuum conditions.

A rupture disc is a sacrificial safety device because it has a one-time-use membrane that fails or ruptures at a predetermined differential pressure, either positive or vacuum. The membrane is usually made out of metal, but nearly any material (or different materials in layers) can be used to suit a particular application. Rupture discs provide immediate response (within milliseconds) to an increase or decrease in system pressure, but once the rupture disc has ruptured it will not reseal.

Rupture discs typically consist of a thin, circular metal disc designed to rupture when the pressure reaches the predetermined limit. The structural design includes various features such as score lines, tensioning devices, or domed shapes to control the burst pattern and ensure a reliable rupture.

Rupture disc sizes range from under 1/4" to 3' or more, depending upon the industry application. Rupture discs and vent panels are constructed from carbon steel, stainless steel, hastelloy, graphite, and other materials, as required by the specific use environment.

Rupture discs are widely accepted throughout industry and specified in most global pressure equipment design codes (ASME, PED, etc.). Rupture discs can be used to specifically protect installations against overpressure scenarios or can be designed to act as one-time valves.

Combination of rupture disc and pressure relief valve

They can be used as single or primary protection devices. They can also be used as a secondary device along with another safety device such as a conventional pressure relief valve (PRV). Rupture discs are very often used in combination with pressure relief valves, isolating the valves from the process, thus saving on valve maintenance and creating a leak-tight pressure relief solution. Check more detailed post on combination of rupture disc with pressure relief valves.

Advantages of rupture discs

Major advantages of the use of rupture discs compared to using pressure relief valves include leak-tightness, no maintenance and cost. Few of the advantages are listed here.

- Quick response: It offers rapid response to overpressure situation by bursting instantly in critical conditions.

- Full opening: Unlike pressure relief valves, these devices open fully in overpressure scenarios and provide unrestricted release of pressurized fluid and ensures efficient pressure relief.

- Non-reclosing: As rupture discs burst completely, they do not reclose after bursting. This clearly indicates that overpressure situation has occurred and there is need of disc replacement.

- Space-saving: These devices are compact in size and allows for easier integration into existing pressure systems.

- When these devices are used in combination with pressure relief valves, maintenance of main relief valves become easy as rupture discs will work as secondary working device.

Applications

Rupture discs are commonly used in petrochemical, chemical, pharmaceutical, food processing and oilfield applications.

Oil and gas: Rupture discs are used in offshore platforms to prevent wellheads, pipeline and production facilities against overpressure. In an oil refinery, a rupture disc installed in a high-pressure distillation column can prevent a failure by relieving excess pressure caused by a sudden increase in feed flow rate.

Chemical processes: Rupture discs are used to prevent explosions caused by runaway reactions, overheating, or improper mixing in chemical reactors.

Power generation: These devices are very important in power plant boilers to protect against excessive steam pressure that can lead to boiler tube failures or steam turbine. In a power plant, a rupture disc installed in a steam turbine's condenser system can relieve excessive pressure resulting from a sudden load rejection.

Rupture disc sizing

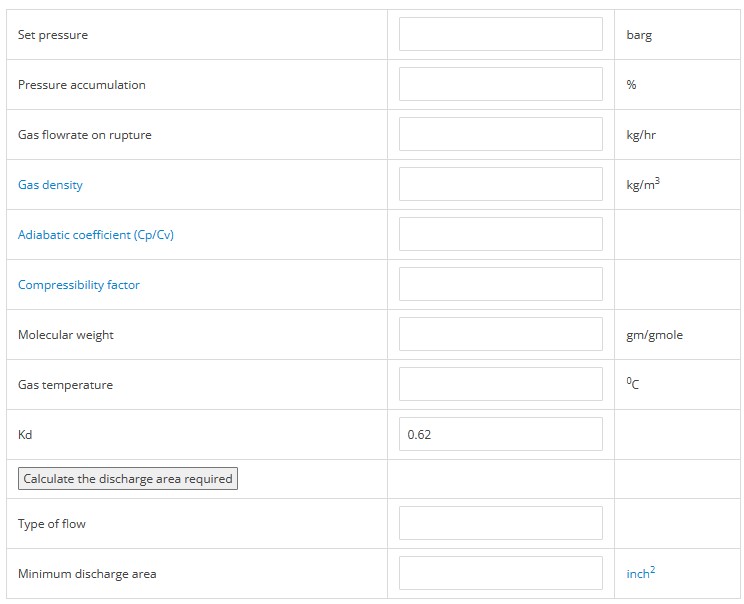

Rupture disc sizing can be readily performed using EnggCyclopedia's rupture disc sizing calculator.

The given calculator can be used to determine minimum area requirement for a rupture disc on a pressure vessel containing vapor.