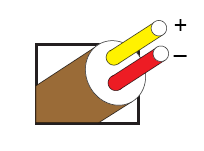

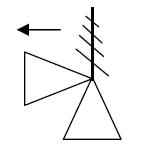

A thermocouple is a sensor for temperature measurement. A thermowell typically consists of 2 dissimilar metals, joined or coupled together at one end, hence the name. When the junction of the two metals is heated or cooled, a voltage is developed that can be correlated with the temperature. The thermocouple alloys are commonly available in the form of a wire.

Types of Thermocouples

Thermocouples are available in different combinations of metals or ''calibrations''.

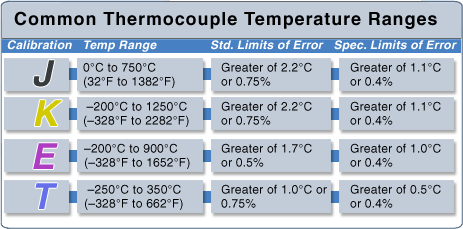

Perhaps the most common ''calibration'' types in use nowadays are J, K, T and E (ANSI coding). There are also other high-temperature types like R, S, B (ANSI coding as well). ASTM E230 standard provides all the specifications for most of the common industrial grades of thermocouples. Of course, there are other standards as well (German, Japanese, French etc) for thermocouples.

Each ''calibration'' type has a different temperature range and environment, although the maximum temperature varies with the diameter of the wire used in the thermocouple.

Selection of thermocouples

In general, the following criteria are considered for selecting a thermocouple:

- Temperature range

- Chemical resistance of the thermocouple or sheath material

- Abrasion and vibration resistance

- Installation requirements and compatibility issues with existing equipment

Major advantages of thermocouples

- Thermocouples can be used to directly measure temperatures up to 2600 degres Celsius.

- The thermocouple junction may be grounded and brought into direct contact with the material being measured.

- Depending on their sheathing material, thermocouples can be used in very hostile environments and optimised for various atmospheres.

- They are significantly more rugged compared to thermistors. This is proven by the fact that quite often, thermocouples are often welded to a metallic part clamped under a screw.

- They can be manufactured right on the spot, either by soldering or welding.

Major disadvantages of thermocouples

- Thermocouple operation is somehow complex with several sources of error. The materials of which thermocouple wires are made are not inert and the thermoelectric voltage developed along the length of the thermocouple wire may be influenced by various factors (corrosion etc).

- The relationship between the process temperature and the thermocouple signal (millivolt) is not linear.