Pumps are an essential part of many industrial and commercial operations, from moving fluids in a water treatment plant to powering hydraulic systems in heavy machinery. Proper maintenance of pumps is critical to keep them operating efficiently and reliably, prevent breakdowns, and extend their lifespan.

Table of content:

Types of pump maintenance

Troubleshooting of pumps

Centrifugal pump inspection schedule

Centrifugal pump maintenance

Precautions against damage of centrifugal pump

Types of pump maintenance

There are several types of pump maintenance, including:

- Reactive Maintenance: Reactive maintenance involves fixing the pump after it has failed or malfunctioned.

- Preventive Maintenance: Preventive maintenance involves regularly scheduled maintenance tasks aimed at preventing pump failures.

- Predictive Maintenance: Predictive maintenance involves using data and analytics to predict when pump failures are likely to occur. This approach relies on monitoring equipment performance and using predictive algorithms to identify when maintenance is necessary.

- Predictive maintenance of pumps using condition-based monitoring: Condition-based monitoring involves monitoring the condition of the pump and performing maintenance based on the equipment's performance data. This type of maintenance is similar to predictive maintenance but focuses more on the specific condition of the pump rather than predicting when failures are likely to occur.

Troubleshooting of pumps

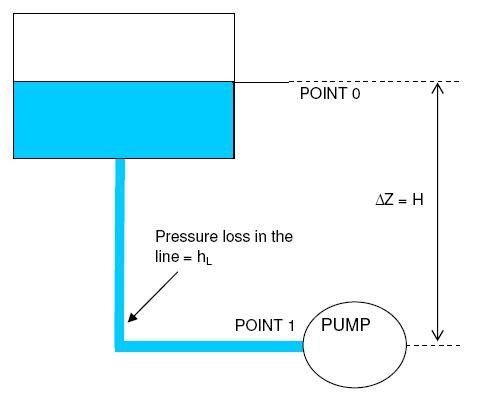

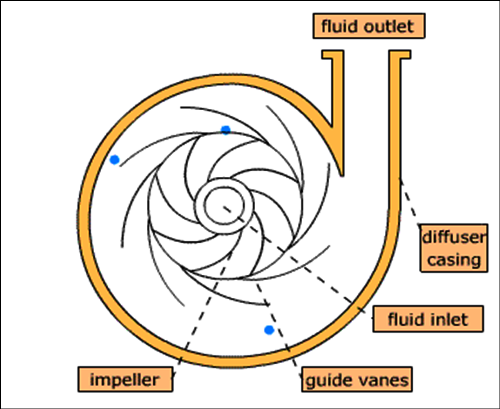

Operating problems in a centrifugal pump which can cause damage to the centrifugal pump can be either hydraulic or mechanical. In the first category (hydraulic), a pump may fail to deliver liquid, it may deliver an insufficient capacity or develop insufficient pressure, or it may lose its prime after starting. In the second category (mechanical), it may consume excessive power or symptoms of mechanical difficulties may develop at the seal chambers or at the bearings or vibration noise or breakage of some pump parts. For example, increased wear at the running clearances must be classified as mechanical trouble but it will result in a reduction of the net pump capacity—a hydraulic symptom—without necessarily causing a mechanical breakdown or even excessive vibration. So it is important to classify symptoms and causes separately.

Daily inspections should be made and any irregularities in the operation of a pump should be recorded and reported immediately. This applies to changes in the sound of a running pump, abrupt changes in bearing temperatures, and seal chamber leakage.

A check of pressure gauges and flow meters and vibration should be made regularly during the day. If recording instruments are provided a daily check should be made to determine whether the current capacity, pressure, power consumption, or vibration level indicates that further inspection is required. Trending charts should be produced to allow observation of changes as a function of time. Certain trends may allow for scheduled outages to address the deterioration of specific performance values.

This post lists problems that often occur with pumps with probable symptoms and the possible causes pertaining to them.

Centrifugal pump inspection schedule

Centrifugal pump inspection should be done regularly. But for different, the level of checking varies with how frequently these pump inspections are carried out. For during routine pump inspections, only the easy to monitor factors such as pressure, temperature, vibration, etc. can be checked. But during quarterly inspections, shaft alignment, and oil levels should also be checked. Some typical inspection schedules are discussed below along with the checklist of activities to be performed.

Routine inspections

Perform the following tasks whenever you check the pump during routine inspections:

•Check the level and condition of the oil through the sight glass on the bearing frame.

•Check for unusual noise, vibration, and bearing temperatures.

•Check the pump and piping for leaks.

•Analyze the vibration.

•Inspect the discharge pressure.

•Inspect the temperature.

•Check the seal chamber and stuffing box for leaks.

•Ensure that there are no leaks from the mechanical seal.

•Adjust or replace the packing in the stuffing box if you notice excessive leaking.

Three-month inspections

Perform the following tasks every three months:

•Check that the foundation and the hold-down bolts are tight.

•Check the mechanical seal if the pump has been left idle, and replace it as required.

•Change the oil every three months (2000 operating hours) at a minimum.

•Change the oil more often if there are adverse atmospheric or other conditions that might contaminate or break down the oil.

•Check the shaft alignment, and realign as required.

Annual inspections

Perform the following inspections one time each year:

•Check the pump capacity.

•Check the pump pressure.

•Check the pump power.

If the pump performance does not satisfy your process requirements, and the process requirements have not changed, then do the following:

1. Disassemble the pump

2. Inspect it.

3. Replace worn parts.

Centrifugal pump maintenance

Routine maintenance (Can be made during pump operation)

Perform the following tasks whenever you perform routine maintenance:

- Clean the bearing bracket from any oil if found.

- Check the oil drain plug.

- Lubricate the bearings.

- Inspect suction and discharge flanges for any leaks.

- Inspect pump casing for any unusual damage signs.

- Inspect the seal.

- If the pump is offline check the coupling and its shims for any damage.

- Make sure that the coupling guard s well tightened to the pump base plate.

- Check that motor alignment bolts are all in place.

Precautions against damage of centrifugal pump

Centrifugal pumps must be monitored regularly, correctly, and accurately according to a specific plan which is made by specially trained personnel. The following six parameters should be regularly monitored to understand how a pump is performing:

- Suction pressure (Ps)

- Discharge pressure (Pd)

- Flow (Q)

- Pump speed (N)

- Pump efficiency (η)

- Power

The advantages of regular monitoring of the pumps are -

- No dismantling of the pump is necessary.

- Offers cost savings and energy savings by increasing the pump availability and reliability coefficients for pumps.

- The time to maintain the pump set may be predicted and planned more accurately and in a qualified manner in line with predictive and planned maintenance strategies.

- If a flow meter is installed to measure process liquid flow, then the pump monitor is able to verify the accuracy of the meter readings by calculating ‘Q’ from the empirical formula for power ‘P’.

In addition, it is very important to monitor some other conditions for the centrifugal pump during normal operation such as:-

- Vibration monitoring: Vibration monitoring for pumps is the best known and most publicized technique and the most powerful for rotating machines such as pumps. Well-aligned and smoother running machines use less energy and in general, also cost less to maintain, balancing is a common solution, temporary or permanent, to high vibration. Vibration instrumentation can also be used for balancing, but simpler methods are sometimes possible and acceptable. Check also this Pump vibration limits as per international standards for efficient operation of pumps.

- Oil level and schedule oil Analysis.