Compressor Surge

Centrifugal compressor surge is seen as a very dangerous and detrimental phenomenon in compressed air systems, dangerous because it causes the compressor to vibrate and detrimental because it causes damage to the compressor parts. Compressor surge only occurs in dynamic compressors (Axial and Centrifugal) due to their nature. To understand compressor surge, a solid understanding of how a compressor actually works is needed.

A centrifugal compressor is a machine that imparts energy to the gas flowing through it. This energy is in the form of velocity and is imparted from compressor impeller to the gas. Kinetic energy of the gas is then converted to pressure head when gas is diffused, slowed down.

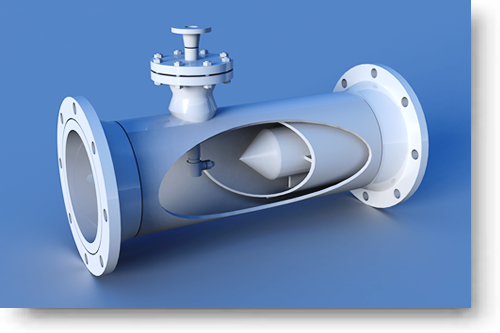

Figure-1 indicates a schematic of a centrifugal compressor system which demonstrates this phenomenon. On the left is the suction side and the right is the discharge side. The centrifugal compressor is in the center. Compressor draws in gas near the center of the compressor impeller with a low energy and imparts kinetic energy as the gas gets hurled in radial direction by the rotating impeller. This kinetic energy is converted to pressure head near the impeller periphery when the gas slows it down in the diffuser and it is forced into the discharge line.

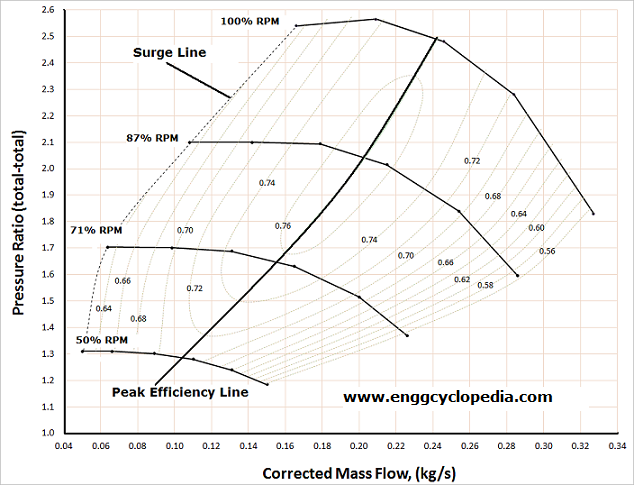

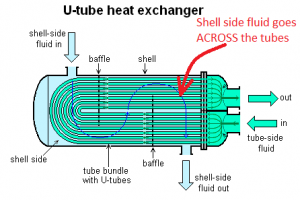

To understand compressor surge phenomenon imagine the situation depicted in following compressor maps. A compressor is running at 80% of its maximum pressure output for 100% rpm producing 8 bar. Then the compressor starts to produce 100% of its possible pressure output at 10 bar. This now puts the operating point on the surge line as shown in the figure-2. As soon as the system pressure in the discharge line reaches 10 bar the compressor begins to surge.

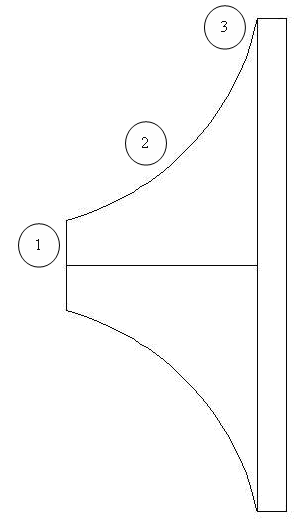

From the context of the compressor impeller

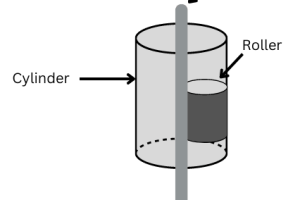

Compressor surge can be understood by the help of schematic of a compressor impeller in figure-3. At point (1) on figure-3, suction end of a centrifugal compressor impeller, fluid has the lowest energy. As the gas moves to point (2) of figure-3, energy of the fluid increases due to kinetic energy imparted by impeller. Energy reaches a maximum at point (3) on figure-3. When the compressor is imparting as much energy as it possibly can, i.e. 100% pressure at 100% rpm and backpressure at pump discharge is too high to be overcome, the fluid flow stalls near point (3). This means the pressure at point (3) increases because the kinetic energy changes to pressure as it slows to a stop. Thus the energy at point (3) is greater than at points (2) and (1) so the flow reverses and flows backward through the impeller.

When the flow reverses, energy and pressure at point (3) is relieved and drops down. Now the compressor can compress fluid, which it does and with the increase of pressure the backflow occurs again and this is the reason why compressor surge is a cyclic phenomenon. Compressor surge puts strain on many of the compressors parts such as the bearings, seals and the impeller itself and thus damage can occur if the compressor is left to surge. The vibration caused by the surging can severely damage the motor compressor coupling and also the baseplate.

There are many methods of surge control in industry today and choosing the right one is difficult and very subjective, so choose wisely.