Boilers are basically vessels used for heating the water and converting it to steam, as the name suggests. Boilers vessels generally use an internal heat source for boiling the water. Generally the steam is used as a utility in process plants and needs to be available at certain temperature and pressure conditions. A boiler is designed based on the desired temperature pressure conditions of the product steam.

Produced steam is then led either to a steam turbine in order to produce electricity or used in various process applications (e.g. used for district heating, cogeneration etc.).

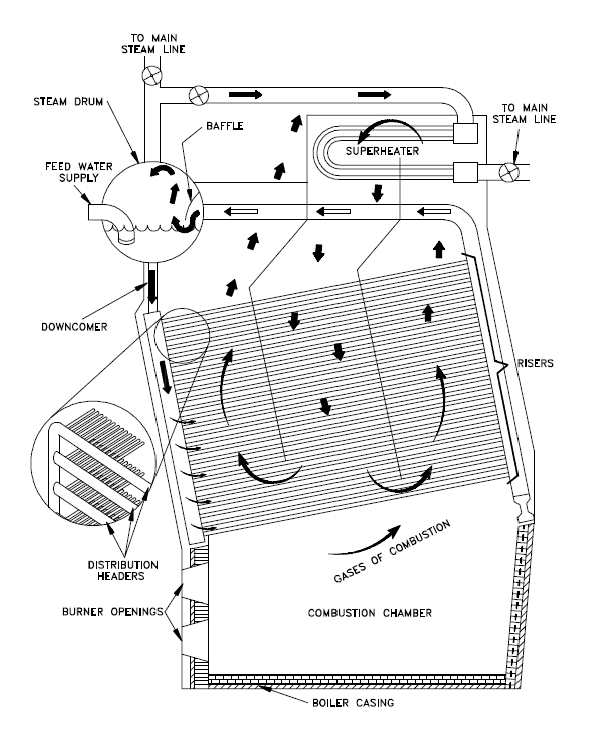

The boiler actually serves as a furnace where air is mixed with fuel (typically oil or coal) in a controlled combustion process, thus releasing large quantities of heat. Water is circulated in the combustion zone through tubes. Water in these tubes is heated due to the heat from fuel combustion, thereby producing steam. The resulting water steam mixture is then carried ahead through the same tubes to a steam drum. Steam is separated from hot water in the steam drum and sent to the steam superheater, where it is further heated and then sent to a steam header for distribution to the steam users.

Figure 1 - Typical boiler schematic

Fuel boiler major parts

Furnace or Combustion chamber is the enclosed space where the fuel combustion takes place, i.e. the place where the air and fuel mix and burn.

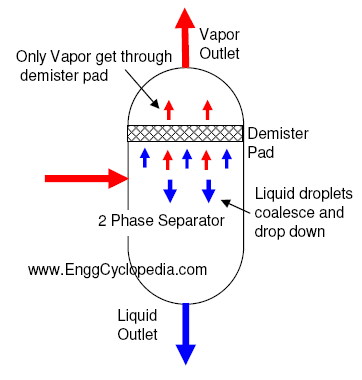

Steam drum separates the steam from the water. Water is contained at the bottom of the drum, whereas steam leaves the drum and enters the steam system. Feedwater enters at the bottom of the drum so that the heating cycle can be repeated.

Downcomers are pipes leading from the top to the bottom of the boiler. Downcomers carry the water from steam drum to the bottom part of the boilers where it enters the distribution headers to be heated in the combustion zone.

Risers are pipes leading from the bottom to the top of the boiler. Water and steam generated in the combustion zone, runs through the risers up to the steam drum. Steam is separated in steam drum and water sent to distribution header through downcomers and the cycle is repeated.

Distribution headers are big pipe headers that transfer water from the downcomers to the risers through a combustion zone where the water gets partially heated to steam from the heat of fuel combustion.

Feedwater pumps are large centrifugal mulsti-stage pumps whose major role is to supply feed water to the steam drum. Once water enters the steam drum, the resulting density difference between hot and cold water is the driving force allowing water to circulate back to the steam drum.

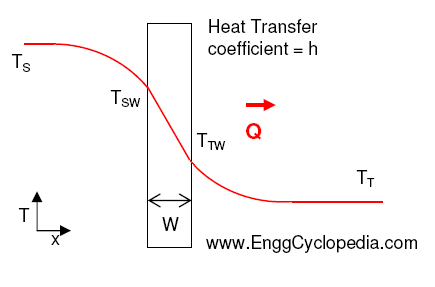

Economizer helps to improve cycle efficiency by preheating inlet feedwater to the boiler. The economizer typically uses heat from the boiler exhaust gasses to raise the temperature of the incoming feedwater.

Evaporator at the outlet of the evaporator the water has received so much heat that it has become saturated steam.

Superheater is installed at the outlet of the evaporator. Passing through the superheater, saturated steam turns into superheated steam. This way, thermal efficiency of the cycle is increased. This would typically be expected from the second thermodynamic law, since superheating increases the average temperature of heat addition to the cycle. A spray desuperheater is typically installed at the outlet of the superheater for protection against excessive temperature.

Flue gas stack is used for releasing the flue gases after they have delivered their heat for warming boiler inlet water. Flue gases are discharged to the atmosphere through the main stack. Since flue gases are corrosive, flue gas stacks must be properly insulated.

Boilers auxiliary systems

Blowdown systems are used during startup of the power plant. During startup, the quality of the water included in the steam drum may be poor. In order to avoid poor quality water of being transformed into steam, this poor quality water is bled from the drum and led to the blowdown system, which typically consists of a blowdown tank and blowdown pumps.

Dosing systems for dosing chemical substances into the boiler feedwater is necessary for feedwater conditioning. Various substances can be dosed in order to prevent scale deposition on boiler's heat exchange surfaces, modulate pH value of feedwater or minimize the presence of oxygen in the water/steam cycle. Substances used to minimize oxygen are also known as oxygen scavengers.

Emissions control or DeNOx system is used for reducing NOx emissions. A Selective Catalytic Reactor (SCR) system, typically consisting of various layers of special-design catalyst modules is used in order to reduce NOx emissions and comply with existing legislation. Chemical substance typically used for this purpose is urea.

Sampling system are used to collect samples through sampling ports installed at strategic locations and led to analysers for establishing that the quality of steam is in accordance with the established standards and in line with the requirements of steam turbine manufacturer.

Soot blowing system is actually a system for cleaning catalyst surfaces of DeNOx system from ash or other foreign particles. Medium typically used for this purpose is compressed air from air control stations.