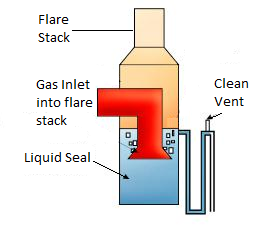

Liquid seals are used at the base of flare stacks to prevent air ingress into the flare stack and further into the flare / vent network.

Flare / Vent Stack

Flare/Vent network in oil refineries, oil and gas processing plants, all the relief devices that can emit hydrocarbons are connected to a flare/vent network. The flare/vent network ends up in a flare or vent stack which continuously emits the hydrocarbons to atmosphere. A vent stack does not burn the hydrocarbons and simply disposes them to the atmosphere at a safe location. Hence gas flow emitted by a vent stack is typically small. When the gas flows in to be continuously disposed are quite high, the gas needs to be combusted before disposing it to the atmosphere. This consumption is achieved in a flare stack. The hydrocarbons are continuously combusted at the flare stack tip before disposing to atmosphere.

Normally the liquid droplets in the flare/vent network are removed from the gas before entering the flare/vent stack using a flare knock out drum. A knock out drum (KOD) is essentially a two phase separator to remove liquid droplets entrained in the gas.

Air Ingress

Typically the flare/vent network along with the vent KO drum operates at a low pressure close to atmospheric pressure. This pressure is actually the built-up back pressure due to the continuous flared or purged gas flow in the vent stack. Pressure at the vent stack tip is atmospheric and back-pressure in the knock out drum is atmospheric pressure plus the frictional pressure drop from continuous venting/purging of the gas.

If the flow of gas to vent/flare stack stops for some reason, there is a possibility of air ingress into the flare stack and into the vent KO drum, vent network. This can result in an explosive mixture of air and hydrocarbons in the vent/flare network, which can be catastrophic.

Liquid seals at base of flare stack

As indicated in figure-1, liquid seal at the flare stack base is essentially a cylindrical volume of liquid into which the gas inlet to flare stack is dipped. This volume allows the flow of flared gas from inlet pipe to the stack in form of bubbles rising through the liquid. Liquid seal volume does not permit any air flow entering the gas inlet pipe, thus preventing air ingress into the flare network.

Another ways to avoid ingress into the flare stack, flare KO drum, flare network are - continuous purge gas flow, flame arresters etc. Although flame arresters are not frequently used due to possibility of obstruction in the flare stack.