Pipeline pigging is a crucial maintenance procedure used in the oil and gas industry to ensure the efficient and reliable operation of pipelines. It involves the use of specialized devices called pigs that are inserted into the pipeline to perform various tasks such as cleaning, inspecting, and separating different products. In this blog post, we will delve into the pipeline pigging procedure, highlighting its importance, key steps involved, and the benefits it offers.

Table of Content:

1.What is Pipeline Pigging?

2. Air pigging & other pigging propellants

3. Hazards and risks involved in pigging a pipeline

4. Precautions to be taken during pipeline pigging

5. Typical procedure for pigging a pipeline

5.1. Steps to be followed at pig launcher end

5.2. Steps to be followed at pig receiver end

6. Typical P&ID for pig receiver and launcher systems

What is Pipeline Pigging?

Pigging operations refers to maintenance practice for pipelines using ‘pipeline pigs’, for cleaning or inspection of pipeline without stopping operation of the pipeline. Pipeline pigs are capsule shaped objects which travel through the pipeline, cleaning the inner walls of the pipeline by brushing action.

Pigs get their name from the squealing sound they make while traveling through a pipeline. Pigging a pipeline usually means inspection and cleaning of the pipeline.

Pig launchers and receivers are also essential for pigging operations. They are vessels used for launching / receiving the pig tool into / from the pipeline. During the pigging of a pipeline, pig is inserted into a pig launcher, using a differential pressure. That pressure pushes it through the length of the pipeline.

Pipe pigs are very frequently used in oil and gas pipelines: they are used to clean the pipes. Also there are "smart pigs" used to measure things like pipe thickness and corrosion along the pipeline. They usually do not interrupt production, though some product can be lost when the pig is extracted. They can also be used to separate different products in a multiproduct pipeline.

Air pigging & other pigging propellants

Different fluids can be used a propellants to push the pig tool through the length of the pipeline. Ultimately the choice of the propellant depends on -

- Nature of the product fluid - is it viscous, gaseous or liquid

- Cost and availability of the propellant

- Length of the pipeline - to determine how much of the propellant would be needed

- Safety concerns - impact of the propellant on pipeline walls, how to dispose it etc.

Compressed air (Air pigging)

Compressed air is commonly used as a pigging propellant - leading to the term 'air pigging'. Air pigging is so common, because air is cheap, readily available, and can be easily disposed of. Almost every processing plant has a compressed air system installed for some reason or other. Also, in the case of air pigging we don't need to worry about disposing off the compressed air. It can be easily vented to atmosphere.

Compressed air is created by forcing air into a smaller space, which increases the pressure of the air. This high-pressure air can then be used to push a pig tool through a pipeline.

Compressed air is a good choice for pigging pipelines that carry non-hazardous fluids. However, it can be difficult to use compressed air to push a pig tool through a viscous fluid. This is because viscous fluids are thick and sticky, and they can resist the movement of the pig tool. In these cases, it may be necessary to use a liquid propellant or a nitrogen or CO2 propellant.

Liquids

Liquids are also used as propellants, especially for viscous fluids. Liquids are more effective than compressed air at pushing a pig tool through a viscous fluid. This is because liquids can flow more easily around the pig tool, which helps to reduce the drag on the pig tool. Using compressed air in such case would require a very high pressure to get the pig tool moving against a viscous liquid.

Liquid propellants can be either water or a special fluid that is designed to be used for pigging. Water is a good choice for pigging pipelines that carry non-hazardous fluids. However, it is important to note that water can corrode pipelines, so it is important to use a corrosion inhibitor if water is used as a propellant.

Nitrogen and CO2

Nitrogen and CO2 are sometimes used as propellants, but they are less common than compressed air or liquids. Nitrogen and CO2 are inert gases, which means they do not react with other substances. This makes them a good choice for propellants in pipelines that carry hazardous fluids.

Nitrogen and CO2 are also used as propellants in pipelines that are used to transport food and beverages. This is because nitrogen and CO2 do not have any flavor or odor, and they do not leave any residue behind.

Hazards and risks involved in pigging a pipeline

Some of the hazards and risks associated with pigging operations are listed here.

- Exposure to high pressure hydrocarbon gas or condensate. Pipelines often carry hazardous materials, and pigging operations can release these materials into the surrounding area. This can be a serious health hazard, and it can also lead to fires or explosions.

- Physical exertion required to operate manual process valves or handling pig. Pigging operations often require workers to operate manual process valves or handle pigs. This can be physically demanding, and it can increase the risk of injury.

- Potential loss of containment of hydrocarbons through leaking flanges or opened valves. Pigging operations can also damage pipelines, which can lead to leaks. Leaks can release hazardous materials into the surrounding area, and they can also create a fire or explosion hazard.

- Risk of igniting released hydrocarbon gas or condensate. Released hydrocarbon gas or condensate can be ignited by a spark or flame. This can lead to a fire or explosion, which can be fatal.

Precautions to be taken during pipeline pigging

- Wear standard Personal Protective Equipment (PPE). This includes safety glasses, gloves, and a hard hat.

- Minimize exposure to the open launcher barrel. If you must be near the open barrel, keep your body behind the barrel and do not lean over the barrel.

- Never assume that a launcher barrel is depressurized. Pressure can build up in the barrel over time, even if it has been closed.

- Never attempt to open the barrel unless you are sure that it is at atmospheric pressure. Use a pressure gauge to check the pressure in the barrel.

- Always check that the launcher barrel is completely depressurized before draining it to the drain/vent K.O. vessel.

- Use a trolley to assist with the insertion or removal of the pig. This will help to prevent injuries from lifting and carrying the pig.

- Follow manual handling requirements to avoid injuries. This includes using proper lifting techniques and avoiding lifting heavy objects over your head.

By following these safety procedures, you can help to prevent accidents and injuries.

Preparation for pigging Operations

The preparation steps are based on the equipment being already shutdown and depressurized:

For pig launcher

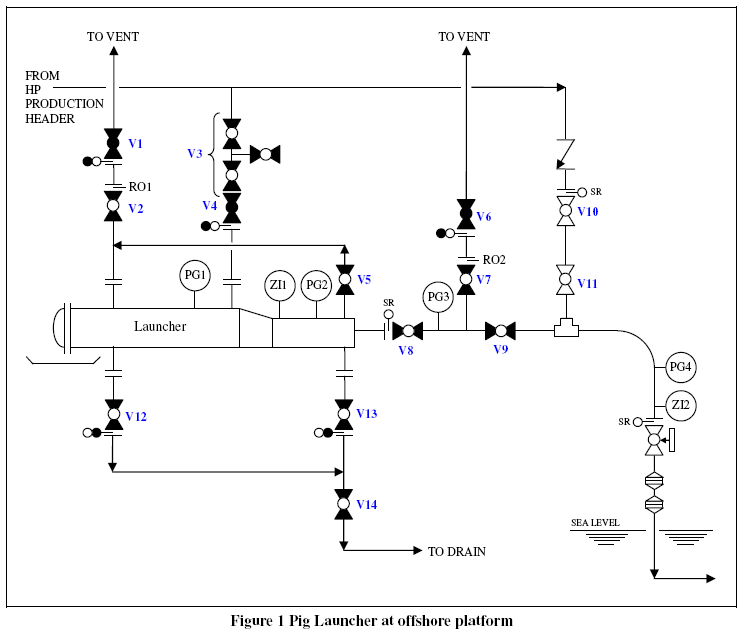

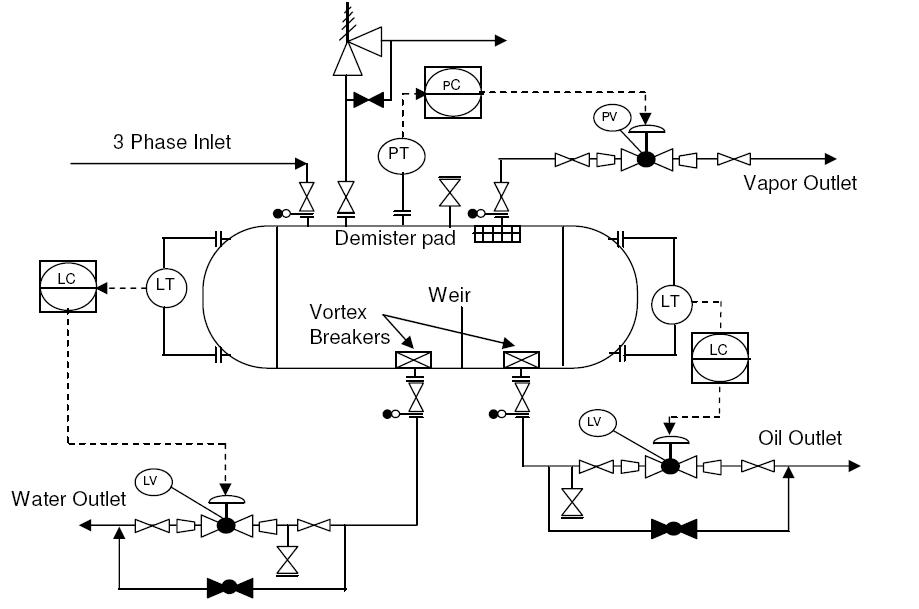

See Figure 1 for references to numbered valves, pressure gauges and pig signals.

Complete the following before attempting to launch a pig:

- Check that the manual launcher valves V8 and V9 are closed.

- Check that vent valve V7 and globe valve V6, between the launcher valves V8 and V9, is closed.

- Check that globe valve V1 and vent valves V2 and V5 on the launcher are closed.

- Check that integral double block valves V3 and globe valve V4 are closed.

- Check that drain valves V12, V13 and V14 on the launcher are closed.

- Check that the electro-magnetic pig signals ZI1 and ZI2 are installed and working correctly with serviceable batteries.

- Request the personnel at the receiving end of the pipeline to confirm that the pig signals are installed and working correctly with serviceable batteries.

- Inform the personnel at the other end of the pipeline that a pig is about to be launched.

For pig receiver

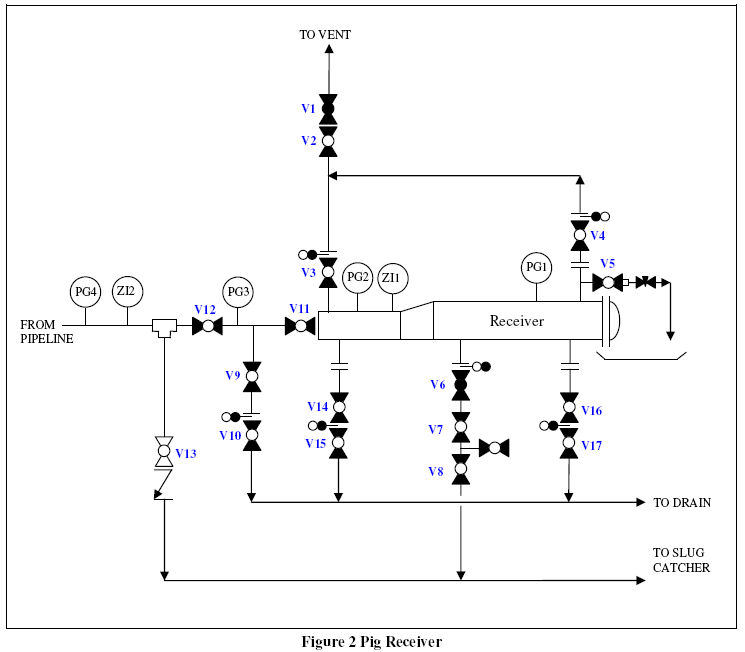

See Figure 2 for references to numbered valves, pressure gauges and pig signals. Complete the following to prepare for receiving a pig:

- Check that drain valves V14, V15, V16 and V17 on the receiver are closed.

- Check that vent valves V1, V2, V3, V4 and V5 on the receiver are closed.

- Check that drain valves V9 and V10 between the receiver valves V11 and V12 are closed.

- Check that globe valve V6 and double block valves V7 and V8 are closed.

- Check that valve V13 on the bypass line is opened.

- Check that the receiver valves V11 and V12 are closed.

Check that the electro-magnetic pig signals ZI1 and ZI2 are installed and working correctly with serviceable batteries.

Typical procedure for pigging a pipeline

Prior to launching a pig from launcher, complete the following valve line-up procedures at pig receiving end of the pipeline to divert the production through pig receiver barrel via its “kicker line”:

- Open the globe valve V6 and double block valves V7 and V8 in the receiver “kicker line”.

- Open the receiver valves V11 and V12.

- Close the valve V13 on the bypass line.

Steps to be followed at pig launcher end

Complete the following steps to load and launch a pig from pig launcher. Refer to Figure 1 for all references to numbered valves, pressure gauges and pig signals.

- Open the globe valve V1 and vent valves V2 and V5 on the launcher. Check that pressure gauges PG1 and PG2 on the launcher barrel are indicating zero pressure.

- Open the vent valve V7 and globe valve V6, between the launcher valves V8 and V9. Check that pressure gauge PG3 between the launcher valves is also indicating zero pressure.

- Confirm that the launcher is fully depressurized by opening a small vent valve on the body of the launcher to atmosphere. Check that there is no sound of escaping gas.

- Open the launcher door.

- Place the pig into the launcher barrel and push it as far forward as possible.

- Close the launcher door.

- Close the globe valve V1 and vent isolation valves V2 and V5 on the launcher.

- Close the vent valve V7 and globe valve V6.

- Pressurize the launcher barrel by opening integral double block valves V3 and gradually opening globe valve V4 in the “kicker line”. Once the launcher is at the same pressure as the export pipeline, close the valves V3 and V4.

- Open the launcher valves V8 and V9 at the downstream of the launcher.

- Open integral double block valves V3 and globe valve V4 in the launcher “kicker line”.

- Close the launcher bypass valves V10 and V11. This will launch the pig into the export line.

- Check that pig signals ZI1 and ZI2 indicate that the pig has left the launcher barrel.

- Open the launcher bypass valves V10 and V11.

- Close integral double block valves V3 and globe valve V4 in the “kicker line” to return all flow to the bypass line.

- Close the launcher valves V8 and V9.

- Open valves V2 and V5 and gradually open globe valve V1 to depressurize the launcher.

- Open vent valve V7 and globe valve V6 to depressurize the pipe spool between valves V8 and V9.

- Close valves V1, V2, V5, V6 and V7 once the launcher is depressurized.

- Pig launcher is then isolated once pigging operations are completed.

Steps to be followed at pig receiver end

Complete the following steps to receive a pig at pig receiver. Refer to Figure 2 for all references to numbered valves, pressure gauges and pig signals:

- Once both pig signals ZI1 and ZI2 indicate that the pig has arrived in the receiver, open valve V13.

- Close globe valve V6 and double block valves V7 and V8 in the receiver “kicker line”.

- Close valve V12 at the upstream of the receiver.

- Open valves V2, V3 and V4 and gradually open globe valve V1 to depressurize the receiver and the pipe spool between the receiver valves V11 and V12.

- Close valve V11 at the upstream of the receiver.

- Once pressure gauges PG1 and PG2 are showing that the receiver is completely depressurized, open drain valves V9, V10, V14, V15, V16 and V17 to drain any liquid from the launcher (and pipe spool between receiver valves) to the drain system.

- Open valve V5 and the DN15 needle valve on the barrel end vent line to confirm that the receiver is fully depressurized. Check that there is no sound of escaping gas.

- Open the door on the receiver and retrieve the pig from the barrel.

- Close and secure the receiver door.

- Close vent valves V1, V2, V3 and V4.

- Close drain valves V9, V10, V14, V15, V16 and V17.

- Pig receiver is then isolated.

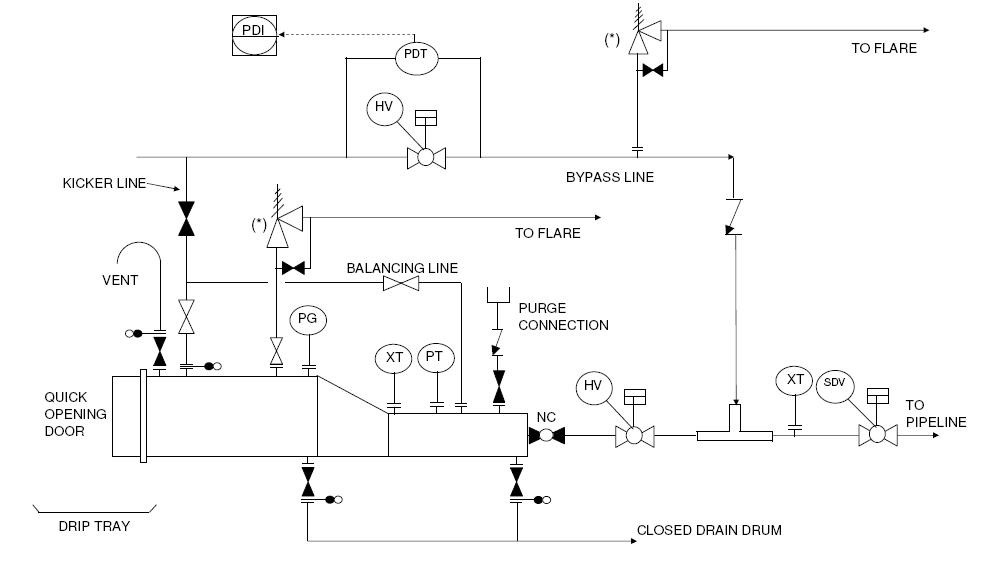

Typical P&ID for pig receiver and launcher systems

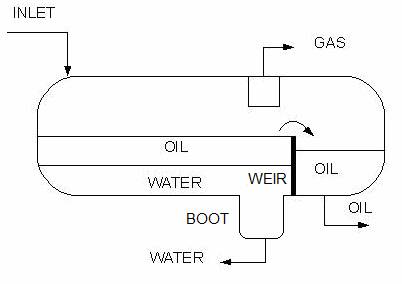

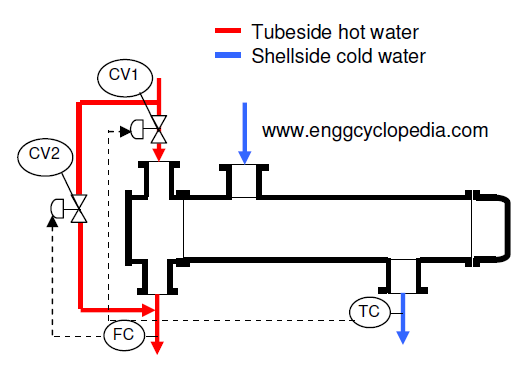

Generally, the arrangement for pig launchers and receivers is essentially the same, except for the difference between 'Kicker line' position for launchers and receivers. Here is a typical piping and instrumentation diagram for a pig trap to indicate the important elements in the design of a pigging system.

You can read more details about designing a pipeline pigging system in this post.