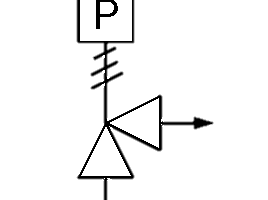

Control valves and their opening for fluid to pass through is operated via actuators. This post is a detailed description of the different parts of a control valve actuator and how it works.

Table of content:

1. Control valve actuator diagram

2. Loading Pressure Connection

3. Diaphragm

4. Actuator spring

5. Actuator stem

6. Yoke

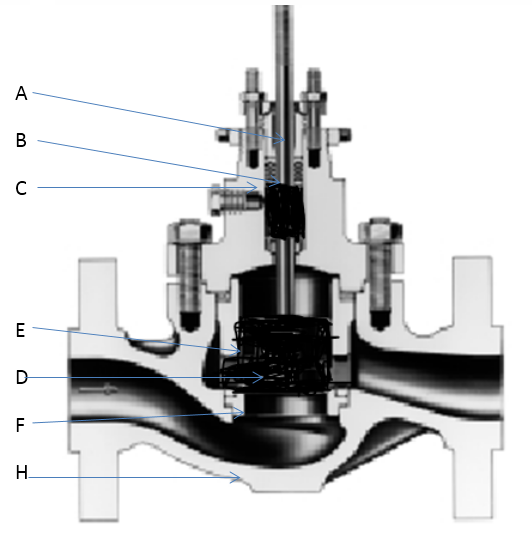

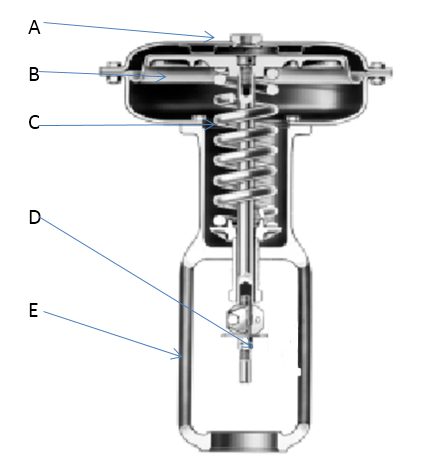

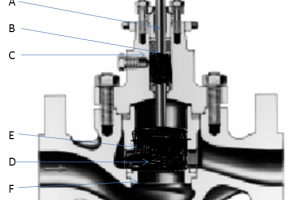

Control valve actuator diagram

Following figure gives details of actuator parts -

A. Loading Pressure Connection

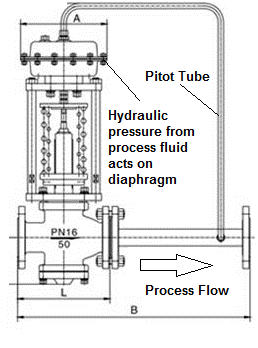

Loading Pressure Connection is the location where a pneumatic (Air or gas) medium enters the actuator body. The location of this depends on the valve's resting position.

For fail open valves the loading pressure connection is from the top side. In this case when valve is not being energized pneumatic medium will flow through the port and the valve will be in open position.

For fail close valve the loading pressure connection is from the bottom side. In such cases when the valve is not being energized pneumatic medium will not flow through port and valve will be in a close position. Loading pressure connection allows the user to control the position of the valve.

B. Diaphragm

Diaphragm is the moving part of actuator and based on the pressure supplied from loading pressure connection it moves up and down to give guiding action control the valve opening.

C. Actuator spring

Actuator spring guides the valve position in case of the failure of the pneumatic supply. Actuator spring is designed to be compressor by pneumatic supply. When the pneumatic signal supply cuts, the actuator spring expands and moves the rod. As a result, the actuator rod will move the valve to open or close the valve opening depending on the type of valve.

In a fail close valve actuator spring ensures that the valve will be in a close position in the event of failure. When pneumatic signal is cut off, spring will expand and move the rod to close the valve. In a fail open valve, actuator spring ensures that the valve remains open even if the pneumatic signal supply is switched off. When the pneumatic signal is cut off, spring will expand and move the rod to open the valve.

The location of spring is different for different conditions. The actuator spring is housed below loading pressure connection in case of fail open valve and it is housed above loading pressure connection in case of fail close.

D. Actuator stem

The actuator stem is the portion of the actuator which connects the actuator to the valve stem. It is responsible for transmitting motion or force generated by the actuator to the valve. The actuator stem is a cylindrical rod like structure.

When the actuator receives signal it generates force or motion, that is transferred to the valve stem through actuator stem. As a result, valve stem moves the valve plug and opens or closes the valve opening to regulate the flow of fluid.

E. Yoke

Yoke is the important component of the valve body that provides mounting surface for the actuator, connects actuator to the valve body and provides clearance to the actuator stem.

Yoke connects the actuator to the bonnet of the valve body. The bonnet is cover that protects valve internals. Yoke also surrounds the actuator stem with clearance. This clearance allows actuator stem to move freely.

To learn about different parts of a control valve and how they work, check out this detailed post.