Process Simulation softwares are used in FEED to size following

- To study selected concept process schemes and to finalize the optimum process scheme

- The know the product rate of fluids with feed product rates or

- The know the feed rate of fluids to get the desired product rates

- To know the utilities or other process requirements for concept selected

- To know the unit operations required to get the desired product quality for concept selected

- To know the heating and cooling requirement to meet the process requirement for concept selected

- To know the power requirement to meet the process requirement for concept selected

- To know rates of by-products and treatment required for by-products for concept selected

- To generate heat and material balance for different cases

- Inputs to various sizing calculations, if applicable, but not limited to

- Separators

- Pumps

- Compressors

- Heaters

- Coolers

- Heat Exchangers

- Control valves sizing

- Flow Control valve

- Level Control valve

- Pressure control valve

- Pressure reducing valve

- Temperature control valve

- Choke valve

- Relief valves

- Rupture discs

- Blowdown valve

- Reactors

- Furnace

- Vent/flare header

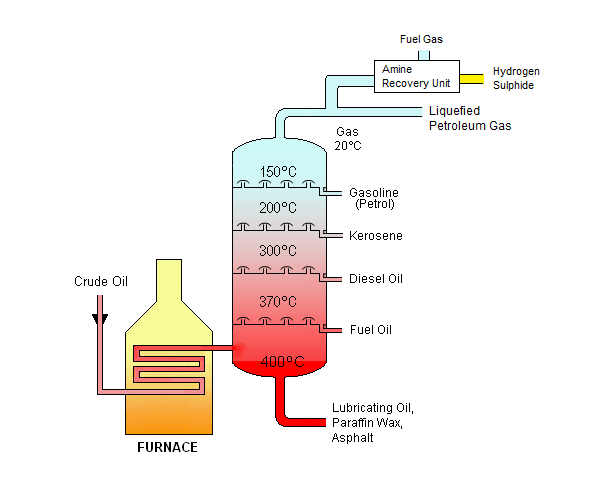

- Distillation columns

- Absorbers columns

- Stripping columns

- Condenser

- Reboiler

- Flash vessel

- Pipe sizing

- Pipeline sizing

- Flow elements and flowmeters sensors

- Pressure gauges and sensors

- Temperature gauges and sensors

- Level gauges and sensors

- Interface level gauges and sensors

- Inputs to other system calculation , if applicable, but not limited to

- Pipeline

- Drain system

- Vent system

- Hot oil system

- Cooling water

- Fuel gas system

- Refrigerant system

- Instrument gas or Air system

- Process data inputs to process datasheets and design specifications for above mentioned equipment / systems

- Provide inputs to engineering disciplines such as Mechanical, Piping, Instrument, Electrical, Pipeline, safety, etc

- In some specialize cases; the dynamic process simulation is performed to optimize the system. Few examples are safety system optimization for process safety time, compressor system optimization for control system finalization and review requirement of hot gas bypass, review surge pressure conditions, etc.

- Finalize the design basis and operating philosophies