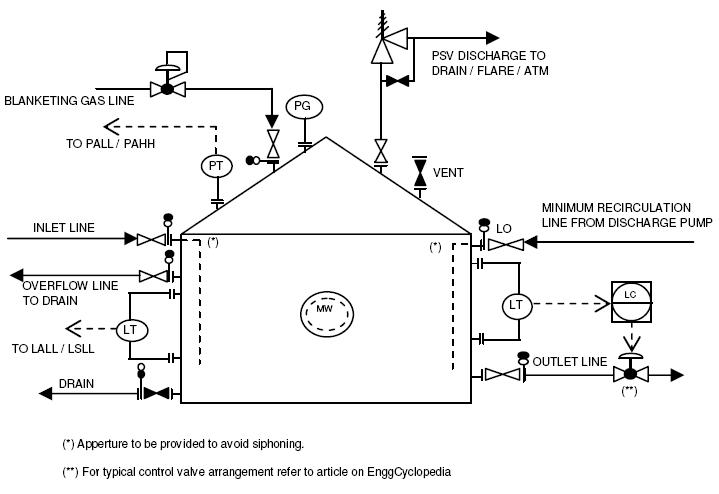

For low pressure or atmospheric storage tanks and process vessels, the design pressure is also low. The tanks are designed to work at near atmospheric pressures. Hence any increase or decrease in the operating pressure needs to be mitigated when it occurs. Overpressure is often mitigated by tank venting. During normal operation the operating pressure may increase or decrease due to following reasons.

- Pressure increase due to liquid moving into the tank

- Pressure decrease due to liquid moving out of the tank

- Pressure increase due to temperature rise

- Pressure decrease due to drop in temperature

Overpressure

Temperature rise and / or liquid coming to the tank cause overpressure which must be relieved by allowing gas to flow out of the tank. This can be achieved by using pressure control valves or open vents to relieve the gas to atmosphere.

Vacuum

Drop in operating temperature and / or liquid flowing out of the tank cause vacuum in tank which must be relieved by allowing gas to flow into tank. This can be done by either a pressure control valve or an open tank vent.

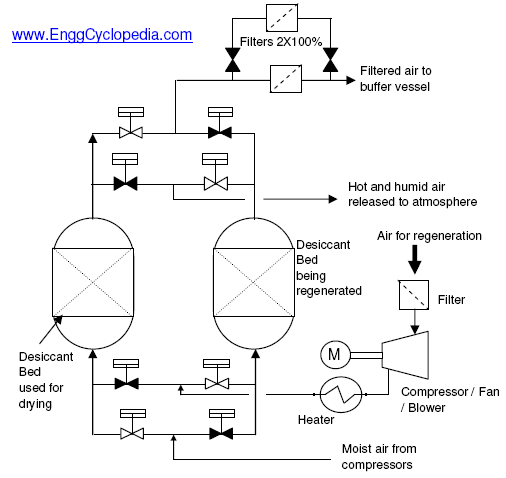

Blanketing gas

For tanks which store hydrocarbons or other gases not desirable to be vented to atmosphere, a blanket of an inert gas such as nitrogen can be used. A pressure control valve on the nitrogen line maintains the tank at atmospheric pressure.

API2000 standard describes the normal tank venting requirements for all the causes of overpressure and vacuum mentioned above. Following calculators and solved sample problems are recommended to be used for reference along with API 2000, to determine normal tank venting requirements for atmospheric storage tanks.

Venting Calculation – Inbreathing

Venting systems are essential to protect tanks and vessels from overpressure and vacuum conditions that can occur during filling, emptying, or temperature changes. Inbreathing valves are a crucial component of the venting system, allowing air to enter the tank as the volume of liquid inside decreases. However, designing an effective inbreathing valve requires accurate venting calculations to ensure that it can provide adequate protection against vacuum conditions. Check this post to explore the basics of venting calculation for inbreathing valves.

Venting Calculation – Outbreathing

Outbreathing is the process by which gases or vapors are released from a storage vessel or container as a result of changes in temperature, pressure, or liquid level. Calculating the proper vent size and capacity for outbreathing is a critical aspect of ensuring the safe storage and transportation of liquids and gases. The venting calculation is done to ensure that the vent is properly sized to prevent overpressure or vacuum conditions that can lead to equipment failure or even explosions.

Emergency tank venting in case of fire

- When atmospheric or low pressure storage tanks are exposed to fire, the liquids vaporise and vapour at high temperature leads to pressure building up of pressure in the tank. Hence, this overpressure needs to be relieved to protect the mechanical integrity of the tank. The tank venting requirement for different types of storage tanks are given in the standard API 2000.