Compressors are mechanical devices that are used to increase the pressure of a gas or vapor by reducing its volume. They are widely used in many industries for a variety of applications, including refrigeration, air conditioning, gas pipelines, and chemical processing.

The basic principle of a compressor is to take a low-pressure gas or vapor and compress it into a high-pressure gas or vapor. This is accomplished by reducing the volume of the gas or vapor, which increases its pressure.'

Table of content

1. Compressors Types

2. Compressors Maps

3. Compressor Calculations

4. Compressor Surge

5. Compressor P&ID Symbols

6. Compressor Choke / Stonewall

Compressor Types

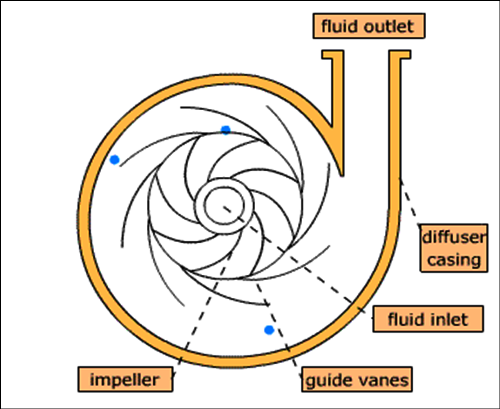

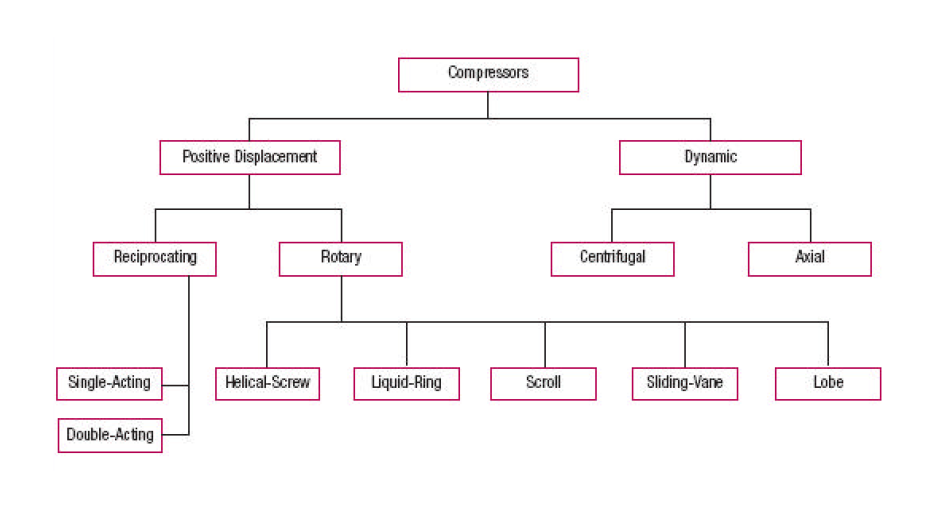

Different types of compressors are classified into two basic categories: Rotodynamic compressors and Positive Displacement compressors. Positive displacement compressors use mechanical means to trap a fixed amount of gas or vapor and then compress it by reducing the volume of the chamber holding the gas. Dynamic compressors, on the other hand, use the energy from the gas flow to increase the velocity of the gas, which in turn increases its pressure. These two broad classes can be further split as:

Rotodynamic compressors

1. Centrifugal compressor

2. Axial flow compressor

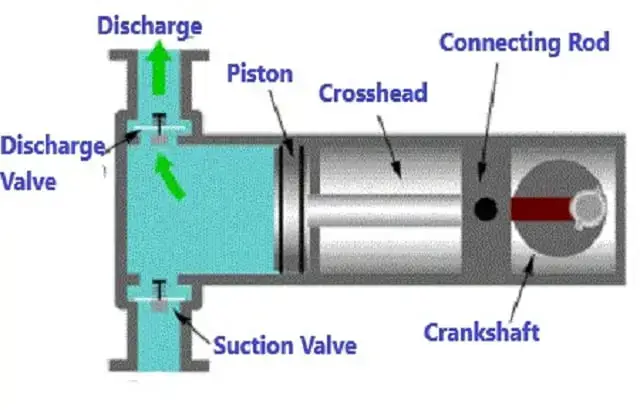

Positive Displacement compressors

1. Rotary compressor

2. Reciprocating compressor

Different classes and types of compressors are described in the given post with the design and operating principles for that equipment.

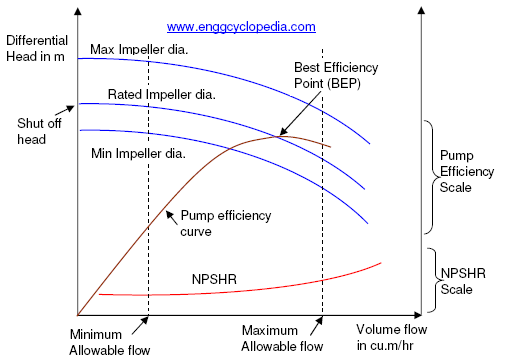

Compressor Maps

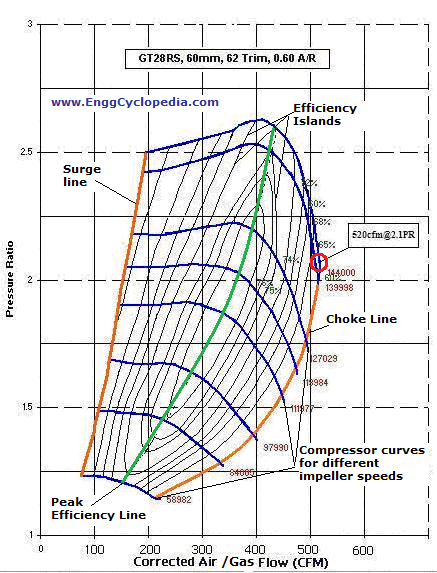

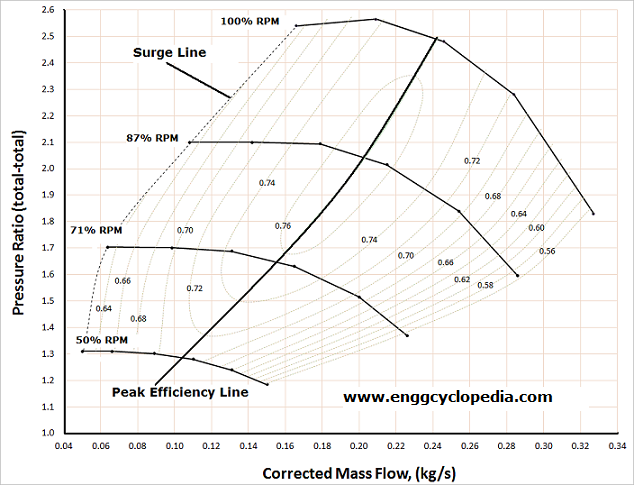

Compressor maps are developed by the manufacturer of dynamic compressors. They are compressor equivalents of the pump performance curves. It is the performance chart of a specific compressor which manufacturer calculates and draws up for the unique design characteristics of that compressor.

Compressor Calculations

The goal of compressor sizing calculations is often to find out the efficiency of the compressor and power required to drive that compressor, given the gas composition, flow rate, temperature & pressure conditions at inlet and outlet pressure requirement.

Take a look at equations frequently used in compressor calculations to determine power and efficiency of the compressor along with their description and significance.

Compressor Surge

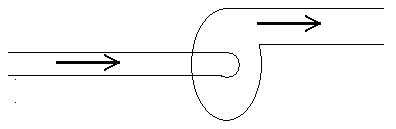

Compressor surge is seen as a very dangerous and detrimental phenomenon in compressed air systems, dangerous because it causes the compressor to vibrate and detrimental because it causes damage to the compressor parts. Compressor surge only occurs in dynamic compressors (Axial and Centrifugal) due to their nature. To understand compressor surge check given post.

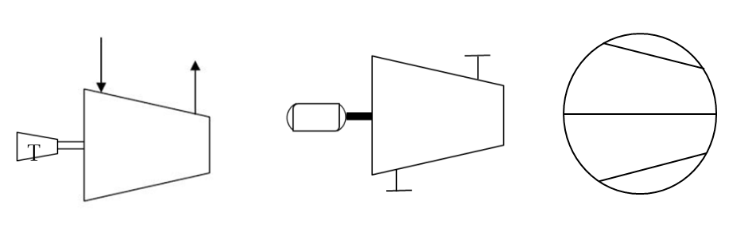

Compressor P&ID Symbols

It is very important to know compressor P&ID symbols to read P&ID diagrams. P&ID diagrams, also known as Piping and Instrumentation Diagrams, are used to map out the design of engineering systems in various industries. These diagrams are essential for problem identification and troubleshooting, as they provide a clear representation of the system's components and their interconnections.

Check commonly used P&ID symbols for compressors in the given post.

Compressor Choke / Stonewall

Compressor choke is an abnormal operating condition for centrifugal compressor. Choking of compressor occurs when the compressor is operating at low discharge pressure and very high flowrates. These high flowrates at compressor choke point are actually the maximum that the compressor can push through. Any further decrease in the outlet resistance will not lead to increase in compressor output.