Casing strings are the series of steel pipes that line the borewell and provide structural support. The casing is placed from the wellhead down to the oil or gas reservoir. This ensures the integrity and stability of the well. In this post theory and functions of casing strings are discussed in detail.

Table of content:

1. What are Casing Strings?

2. Casing String Functions

What are Casing Strings?

Casing strings are connected sets of series of steel pipes which run through the wellbore from wellhead to the oil reservoir. Sections of pipe are connected with each other using couplings, to suit a particular wellbore. Normally length of a typical pipe section is 40ft or 12m.

These sections are male threaded on both ends which allows them to connect. The connection between pipes are connected by couplings which are female threaded on both ends. A continuous casing string is created by screwing male threaded end of one section into the female threaded end of another section.

Threading and coupling design ensures secure and tight connection. This helps in ensuring that the wellbore is properly sealed and capable of sustaining high pressure and forces encountered during drilling operation.

The drilling of well is typically done in different sections rather than using the same bore through all the sections to ensure that fluids from different formations do not mix.

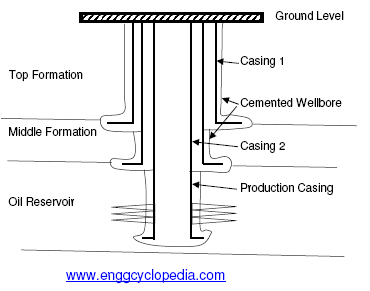

- Normally a well is drilled by in different sections, separating these sections by different casing strings as shown in the figure.

- For example, after the wellbore is drilled through the top formations containing fresh water, before going to deeper formations this section of the well has to be sealed off.

- This is achieved by running a casing string down the wellbore and filling the annulus between casing and wellbore by cement.

- Once a top section is sealed in this fashion, another smaller bore is drilled below this first section of the well.

- The new section is sealed using a smaller casing contained within the first section casing.

The well is effectively divided into separate compartments by installing different casing strings and sealing of each section. Thus subsequently smaller casing strings contained within other casings, seal off different formations until the smallest of them penetrates the oil reservoir.

Casing String Functions

- Various casing strings for different sections of the well protect various tubing carrying fluids.

- Casings maintain the wellbore wall in place and prevent movement of formation structure into the wellbore.

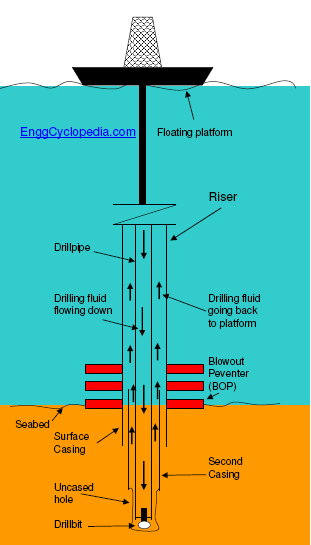

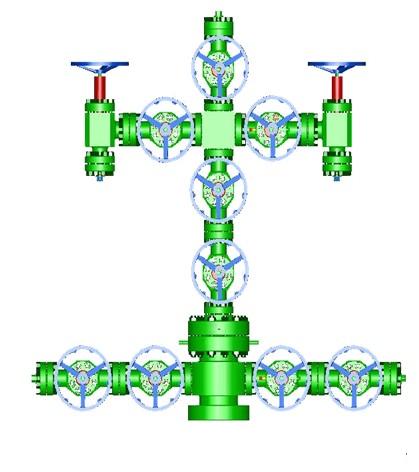

- Casing strings provide strength and pressure integrity for installing the wellhead equipment, including Blow Out Preventer (BOP).

- A casing string serves to isolate different formations from each other when it is cemented to the wall of wellbore. This way mixing of fluids from different formations through the wellbore is prevented.

- During drilling, casings help by sealing off low pressure, low strength formations from high pressure, high strength formations so that they can be separately and safely drilled.

- Casings protect fresh water aquifers from contamination from other fluids.