Similar to the Reverse Temperature Detectors, thermistors are also temperature sensitive resistors.

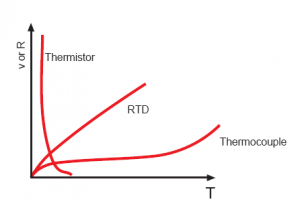

Out of three types of sensors (RTD, thermocouple, thermistor), thermistors exhibit by far the the biggest parameter change with temperature or in other words, they are most sensitive towards temperature change.

Advantages of thermistors

Thermistors generally consist of semiconductor materials. Most thermistors in use nowadays are characterized by a negative temperature coefficient, meaning that their resistance decreases with increasing temperature. Temperature coefficient change can be as high as several percentage factors per degree Celsius. Consequently, thermistors are able to detect even the smallest temperature changes, which would otherwise go undetected with a reverse temperature detectors or thermocouple.

The price to be paid for this high sensitivity is loss of linearity. Thermistor behavior is extremely non-linear and as such, thermistor readings are strongly dependent on process parameters. Consequently, thermistors are not as widely standardized as RTDs or thermocouples.

Figure 1 - Typical thermistor curve showing its non-linear behaviour compared to RTDs and thermocouples

Disadvantages of thermistors

The high resistivity of a thermistor is a significant advantage, since it leads to very small errors, which could be even hundreds time smaller compared to measurement errors of RTDs.

In general, a thermistor is more fragile than RTDs and thermocouples and therefore requires delicate handling and mounting. Another drawback of them is that because they consist of semiconductors, they are more prone to permanent de-calibration (drifting out of their specified tolerance). Contrary to applicability of RTDs and thermocouples, use of thermistors is generally limited to a temperature range of few hundred degrees Celsius.

Small mass of thermistors also makes them very really susceptible to self-heating errors.