A pump operating at lower capacity than design limits can suffer from recirculation which occurs internally in the pumps. This recirculation is different than the minimum recirculation flow required for centrifugal flow and can be a source of serious problems.

When the capacity of a pump is reduced by throttling (or as a result of an increase in system head), a secondary flow called recirculation begins. All impellers have a critical capacity at which recirculation occurs. The capacities at which suction and discharge recirculation begin can be controlled to some extent by proper design, but recirculation cannot be totally eliminated.

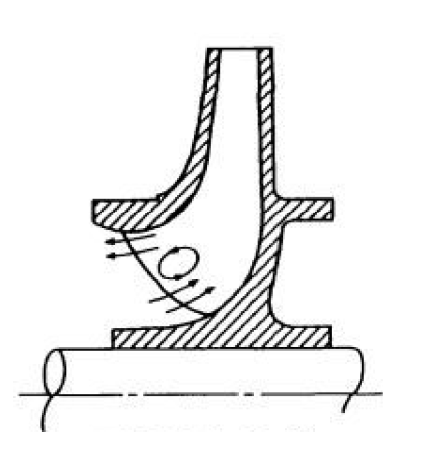

Recirculation is a flow reversal near either the inlet or the discharge tips of the impeller vanes.

Pump suction recirculation

Suction recirculation is the reversal of flow at the impeller eye. A portion of the flow is directed out of the eye at the eye diameter and travels upstream with a rotational velocity. As a result of this recirculation, vortices are formed. Collapsing of the vortices produces noise and cavitation at the suction of the pump.

Recirculation at discharge

Discharge recirculation is the reversal of flow at the discharge tips of the impeller vanes. Resulting vortices cavitate and usually attack the pressure side of the vanes.

In general, the capacity at which suction recirculation occurs is directly related to the design suction specific speed of the pump. The higher the suction specific speed, the closer the beginning of recirculation will be to the capacity at best efficiency.

Experience and tests have shown that pump recirculation and associated risks are relatively low in pumps with a discharge flow of 2,500 gpm or less at heads up to 150 feet. For these pumps, energy levels of the vortices may not bee high enough, even if the pump operates close to the recirculation zone. As a general rule for such pumps, the minimum operating flows can be as low as 50% or recirculation values for continuous operation and as low as 25% for intermittent operation.

Effects and damages from recirculation

Pump recirculation can cause surging and cavitation even when the available NPSHA exceeds the supplier's published NPSHr by considerable margin.

Suction recirculation typically produces a loud crackling noise in and around the suction of the pump. Recirculation noise is of greater intensity than the noise from low NPSH cavitation and is a random knocking sound. Discharge recirculation will produce the same characteristic sound as suction recirculation with the exception that the highest intensity is noticed at the discharge volute or diffuser.

Corrective procedures against pump recirculation

It is to be noted that each impeller design has specific recirculation characteristics. Therefore, these characteristics can not be modifed without altering the design.

A detailed analysis of the symptoms caused by recirculation should probably take the following corrective procedures into consideration:

- Increase the output capacity of the pump.

- Install a bypass line between the discharge and the suction of the pump.

- Use a harder material for the impeller to reduce the rate of cavitation damage.