Flash point is a property characterizing flammable gases and liquids. By definition, the flash point of a flammable fluid is the lowest temperature at which the fluid can form an ignitable mixture with the air. Flashing point of fluids and fluid mixture is used for evaluating potential hazard which can be caused by leakage of that fluid. This is the basis for hazardous area classification of that particular flammable fluid leakage source.

Tests and standards for flash point measurement

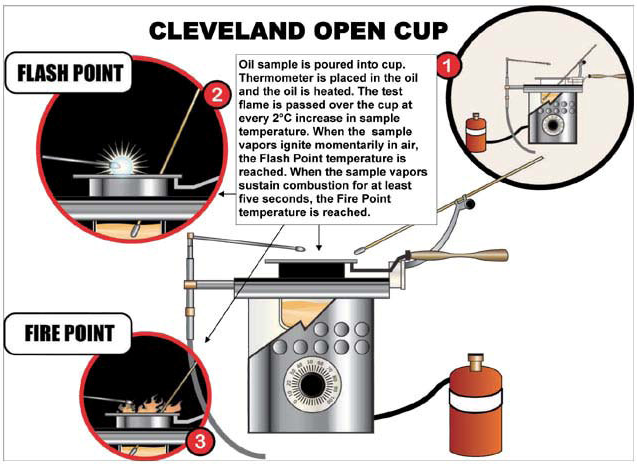

In order to measure flash point, we need to have an ignition source in the vicinity of vapors evolving from a flammable liquid. Then the temperature of the concerned flammable liquid is gradually increased in small steps. When the flash point temperature is reached, vapors of flammable liquid in question ignite momentarily and cease to burn when the source of ignition is removed.

The flashing point is sometimes confused with two other terms:

- the auto-ignition temperature, which does not require an ignition source and

- the fire point, the temperature at which the vapor continues to burn after being ignited.

Cleveland Open Cup method for flashing point

Flash point for petroleum products, except fuel oils, is typically tested by Cleveland Open Cup method, which is described in ASTM D92 standard. This method is generally applicable to all petroleum products (except fuel oils) with flash points above 79 degrees Celsius and below 400 degrees Celsius. Testing device typically consists of a test flame applicator, a brass test cup, a thermometer, heating plate and electric heater.

Figure 1 - Typical Cleveland open cup testing method

Pensky-Martens Closed Cup method

Fuel oils (diesel, kerosene, heating oil etc) as well as residual fuel oils are typically tested with Pensky-Martens Closed Cup method, which is presented in ASTM D93 standard.

ASTM D93 standard basically lists two testing procedures: Procedure A and Procedure B.

Procedure A is mostly applicable to distillate fuel oils and new lubricating oils, whereas Procedure B is applicable to all grades of residual fuel oils and mixtures of petroleum liquids with solids. Heating rate (through the use of electric heater) of Procedure A is bigger compared to Procedure B. On the other hand, Procedure B typically has a bigger stirring speed compared to Procedure A.

Testing device of ASTM D93 typically includes a brass test cup with pilot flame, test flame reference bead, built-in stirrer, thermometer and electric heater.

Figure 2 - Typical Pensky Martin Closed-Cup testing device