Hazardous areas are defined by taking into consideration the various dangers presented by potentially explosive atmospheres. This hazardous area classification enables protective measures to be taken.

There are basically two (2) major standards governing hazardous areas classifications:

- classification in accordance with International Electrotechnical Committee (IEC),

- classification in accordance with National Electric Code (NEC).

IEC classifies hazardous areas in Zones, whereas NEC classifies hazardous areas in Classes and Divisions.

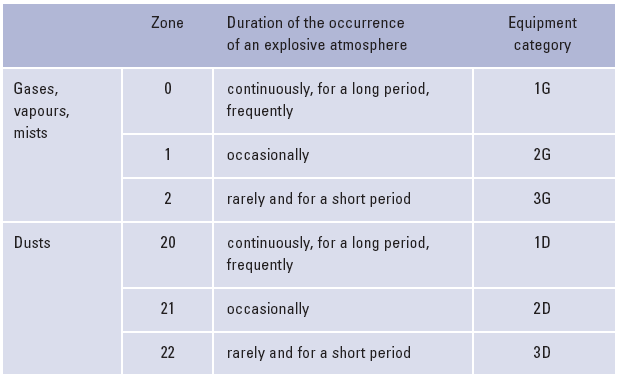

International Electrotechnical Committee (IEC) Hazardous Area Classification

- Zone 0: An area where an explosive gas-air mixture is continuously present or present for long time (continuous hazard, whose estimated duration is higher than 1000 hours/year)

- Zone 1: An area where an explosive gas-air mixture is likely to occur during normal operation (intermittent hazard, whose estimated duration is between 10 and 1000 hours/year)

- Zone 2: An area where an explosive gas-air mixture is not likely to occur but even if it does, its presence is only limited for a short period of time (possible hazard, whose estimated duration is less than 10 hours/year)

Installation requirements for Zone 0 are more stringent than Zone 1 areas and requirements for Zone 1 areas are more stringent than Zone 2 areas.

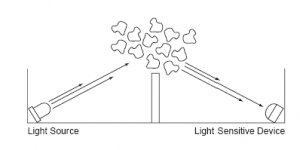

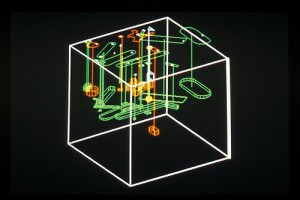

Picture 1 - Areas classification example according to International Electrotechnical Committee (IEC)

National Electric Code (NEC) Hazardous Area Classification

- Class I: any location where flammable gases or vapours are/may be present in sufficient quantity to produce an explosive or ignitable mixture.

Class I classification is further broken down to Class I, Division 1 and Class I, Division 2.

Class I, Division 1 locations are areas where ignitable concentrations exist under normal operation, frequently due to repair- maintenance operations carried out, breakdown or malfunctioning equipment-process.

Class I, Division 2 locations are areas where:

- liquids or gases are stored, handled or processed in containers or closed systems from where they could escape in case of abnormal operation (fire, rupture etc) or faulty operation.

- ignitable concentrations are usually avoided by use of various ventilation systems, which could become really dangerous environments upon failure, shutdown or malfunction of these ventilation systems.

Class II locations are areas which are charasterised as dangerous due to the presence of combustible dust.

Class III locations are areas which are deemed as perilous because of the presence of ignitable fibers or flyings.

Although there is any direct correlation between IEC and NEC classifications, the following classification comparison might be useful:

|

HAZARDOUS MATERIAL |

NEC STANDARDS |

IEC EURONORM STANDARDS |

|

Gas or Vapor |

Class I, Div. 1 Class I, Div. 2 |

Zone 0 and 1 Zone 2 |

|

Dust |

Class II, Div. 1 Class II, Div. 2 |

Zone 10 Zone 11 |

|

Fibers and Flyings |

Class III, Div. 1 Class III, Div. 2 |

Zone 10 Zone 11 |

Table 1 - Hazardous Areas classification comparison table