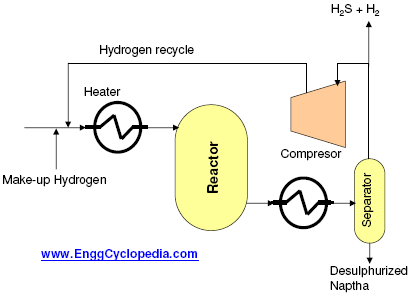

The term 'residence time' is usually used for continuous process flow through a process vessel, equipment or even a piece of pipe. Residence time for a vessel, equipment or a piece of pipe can be defined as the average time spent by a random fluid particle passing through the vessel during a continuous process.

Various methods can be used to calculate the residence time of fluid for a vessel. The most simple way is to divide the volume of the vessel normally occupied by the fluid by normal flowrate of the fluid through that vessel.

The term residence time has special significance for process equipments such as two phase or 3 phase separators, reactors, distillation columns and even heat exchangers. More residence time usually means more degree of separation, higher conversion in a reactor or more heat transfer. But a high residence time also means a large equipment or a vessel, leading to large capital costs.

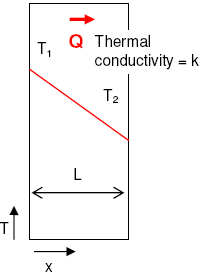

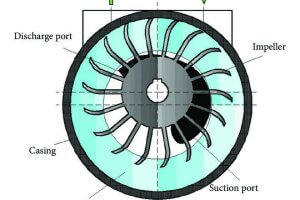

But residence time does not depend directly and only on the equipment or vessel size. The shape of the vessel and flow pattern through the vessel also plays an important role in determining residence time. For example swirling flow patterns in a cylindrical vessel offer more residence time instead of simply letting in a radial flow.