Liquid ring compressors are rotary type positive displacement compressors that use a liquid as the working fluid to compress gases. The purpose of this post is to provide a better understanding of how liquid ring compressors work, their benefits, and limitations.

Table of content:

1. Introduction

2. How Do Liquid Ring Compressors Work?

3. Liquid Ring Compressor Advantages

4. Liquid Ring Compressor Disadvantages

Introduction

Liquid ring compressors use a liquid, typically water or oil, as the sealing and cooling medium. It is commonly used in applications where a high volume of gas or vapor needs to be compressed and handled without contamination or damage.

The liquid ring serves as a seal to prevent gas from escaping back to the inlet port. The liquid absorbs the heat generated during compression. The resulting increase in temperature causes the liquid to expand and seals the compression chamber. The liquid also lubricates the rotor and blades, reducing wear and increasing efficiency.

Liquid ring compressors are commonly used in the chemical, petrochemical, and oil and gas industries for compressing gases that contain corrosive or toxic components, such as hydrogen chloride or ammonia. They are also used in vacuum applications, such as in the production of vacuum-formed plastics, where a continuous and reliable vacuum is required.

How Do Liquid Ring Compressors Work?

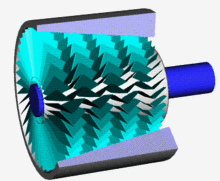

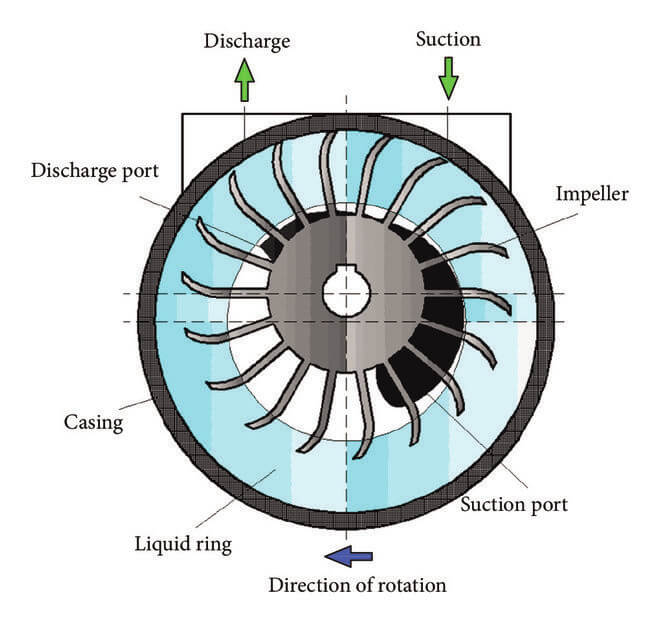

Liquid ring compressor operates by using a rotating impeller with blades inside a cylindrical housing. That cylindrical housing is partially filled with a liquid, typically water or oil. The impeller is mounted off-center so that as it rotates, it creates a series of chambers with varying volumes.

The rotor is the central rotating component of the liquid ring compressor, with blades mounted to it that create the compression chambers. The housing is the cylindrical structure that encases the impeller and the liquid. The inlet port is where the gas enters the compressor, while the outlet port is where the compressed gas exits the compressor.

- As the impeller rotates, the liquid is centrifugally forced against the walls of the housing, creating a liquid ring.

- When the impeller blades pass the inlet port, gas is drawn into the compression chambers.

- As the impeller continues to rotate, the volume of the chambers decreases, compressing the gas.

- Finally, the compressed gas is discharged through the outlet port.

The liquid also provides a sealing function between the impeller and the housing, ensuring that the gas remains contained within the compression chambers.

The cooling mechanism in a liquid ring compressor is provided by the liquid itself. The liquid absorbs the heat generated by the compression process and is then cooled, either through an external cooling system or through a heat exchanger. The cooled liquid is then recirculated back to the compressor to provide a continuous supply of cooling and sealing fluid.

Liquid Ring Compressor Advantages

Liquid ring compressors offer several unique advantages compared to other types of compressors. Here are some of the key advantages of liquid ring compressors.

- Liquid ring compressors can handle a wide range of gases, including gases that contain moisture and particulate matter, as well as corrosive gases, without damage to the compressor.

- They are relatively simple in design, making them easy to operate and maintain.

- They can operate in harsh environments, including high temperatures and high altitudes.

- They provide a continuous supply of cooling and sealing fluid.

- They are less prone to wear and tear compared to other types of compressors.

Liquid Ring Compressor Disadvantages

Some of the key disadvantages of liquid ring compressors are listed here.

- They are generally less energy-efficient compared to other types of compressors.

- Liquid ring compressor require a source of cooling water to maintain the temperature of the working fluid, which can add to the operating costs and complexity of the system.

- Liquid ring compressors typically have limited maximum discharge pressures compared to some other types of compressors, which can limit their use in applications where high pressures are required.

- They are also limited in terms of the flow rates they can achieve.