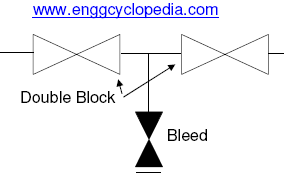

Double block and bleed valve assembly

Double block and bleed valves are used to achieve positive isolation when performing maintenance activities in a live process plant. Typically two block valves and a bleed valve are manufactured as a single assembly and this valve manifold can be readily installed for isolation purpose.

Double block and bleed assembly is usually used for critical process service, such as high pressure system or toxic, hydrocarbon or hazardous process fluids. For non-critical service, single block and bleed valve assemblies must be used.

To perform positive isolation while performing maintenance, repair or shutdown activities, double block and bleed can be used in the following way. Both the block valves are closed first. The shutdown side of the block and bleed assembly is then drained/vented/purged to make ready for maintenance. The bleed in the valve assembly is used to relieve the trapped process fluid from space between the two block valves. This way two isolation valves separate the shutdown side from process fluids.

Double block and bleed valves are also often used with spectacle blind or blind spacers to provide positive isolation. Double block and bleed valve assemblies allow fewer potential leakage paths compared to traditional multiple valve installations, thus increasing safety of the design.

Usually, ball valves are used as block valves or isolation valves and ball or needle valves are used as bleed valves or drain valves in the block and bleed assembly.

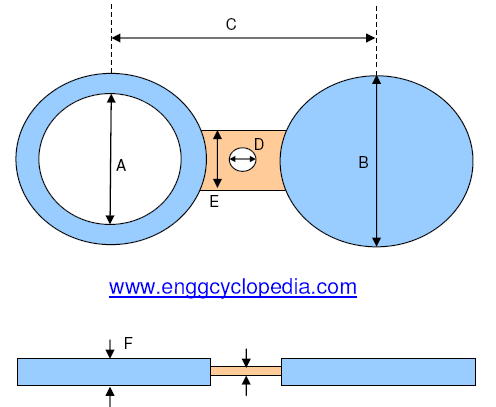

Cartridge type standard length double block and bleed valves have a patented design with two ball valves and a bleed valve into one compact cartridge type unit with ANSI B16.5 tapped flanged connections. This configuration allows the valve assembly to have same face-to-face dimensions like a single block ball valve, thus allowing more space for other devices to be installed on the same line.