Ball valves are among the least expensive and most widely used valves in process industries. A ball valve uses hollow, perforated and pivoting ball to control the flow of fluid through it. The ball contains hole or port in the middle that allows or blocks the fluid flow depending on the application.

Ball valves are preferred in situations where quick and frequent on/off operation is required, as they have a quarter-turn operation (90o rotation) to open or close the valve completely. In this post structure, parts and types of ball valve have been discussed thoroughly along with advantages, disadvantages and applications of it.

Table of content:

1.What is a ball valve?

2. How does a ball valve work?

3. Parts of ball valve

4. Types of ball valve

5. Advantages

6. Disadvantages

7. Applications of ball valves

What is a ball valve?

Basic design of a ball valve is similar to that of a plug valve and ball valves are sometimes also known as 'spherical plug valves'. Instead of a plug, ball valve uses a spherical ball sandwiched between two sealing rings in a simple body. This ball has a hole to allow the fluid flow through it.

Ball valves are produced in top-entry and split-body fashion for the ease of valve assembly. Generally these valves are produced with soft non metallic seats. PTFE, graphite, steel powder, glass are some of the common materials used for this purpose. However metallic sealing rings maybe preferred for handling of abrasive fluids or high pressure, high temperature applications.

How does a ball valve work?

The design of a ball valve revolves around the hollow, perforated ball and its rotational movement. When the valve is open, the ball is rotated so that the bore aligns with the flow direction, allowing the fluid to pass through the valve unobstructed. This position is often referred to as the "open" or "on" position.

Conversely, when the valve is closed, the ball is rotated 90 degrees, causing the bore to be perpendicular to the flow direction. In this position, the ball blocks the flow of fluid, creating a tight shut-off. This position is commonly referred to as the "closed" or "off" position.

The rotation of the ball is achieved by turning the stem through the actuator or handle. As the stem rotates, it transfers the motion to the ball, enabling precise control over the flow of fluids. Handle will be in line with the axis of the valve when it is in the open position and at right angles to the valve axis when valve is in the closed position.

Since the friction involved in the rotation of the ball is only generated between the ball and the sealing rings, the frictional resistance is low. Hence the torque required to rotate the valve is also low. Generally, large ball valves can be operated using a handwheel with reduction gearing.

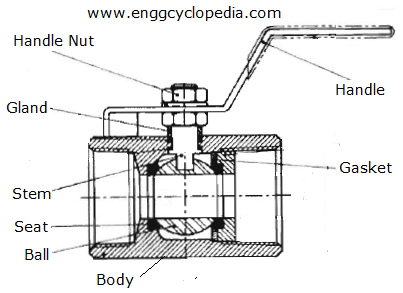

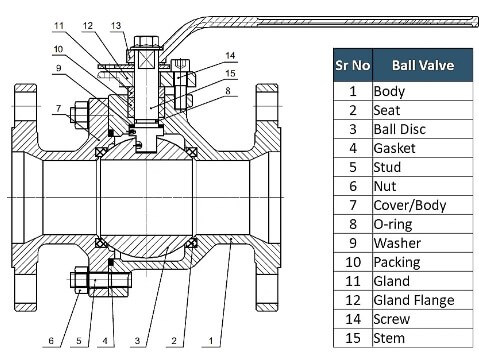

Parts of ball valve

A ball valve consists of several key parts that work together to regulate fluid flow. Here are the main components of a ball valve.

Body: The body is the outer casing of the valve, typically made of materials such as brass, stainless steel, or PVC. It houses the other components and provides structural integrity to the valve.

Ball: The ball is the central component of the ball valve. It is a hollow, spherical or cylindrical object with a hole, known as the bore, drilled through its center. The ball is typically made of materials like brass, stainless steel, or plastic.

Seat: The seat is a sealing surface located inside the valve body. It forms a tight seal with the ball when the valve is closed, preventing any fluid leakage. Seats are commonly made of elastomers such as PTFE (polytetrafluoroethylene) or Teflon for their excellent chemical resistance and low friction properties.

Stem: The stem is a rod-like component that connects the ball to the actuator or handle outside the valve. It transfers the rotational motion from the actuator to the ball, allowing for control of fluid flow. Stems are typically made of stainless steel for strength and corrosion resistance.

Actuator/Handle: The actuator or handle is the mechanism used to operate the valve. It can be a lever, handwheel, or motorized actuator, depending on the size and type of the valve. The actuator enables the user to rotate the stem and, consequently, the ball to control the flow of fluid.

Packing: Packing is a material used to provide a seal around the stem to prevent any leakage along the stem. It is usually made of materials which can withstand high temperatures and offer good sealing properties.

Types of ball valve

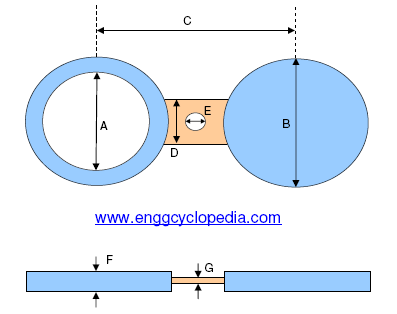

The ball valves can be classified on different basis such as end to end dimensions, seat material, inner diameter of ball hole, body construction or pressure relieving capability of a ball valve. Few types of ball valves has been discussed in the given section.

Full port ball valve

This type of a ball valve has a bore diameter equal to pipe's inner diameter. This means that opening through the valve is unobstructed which allows for maximum flow capacity. This design minimizes flow restriction and pressure drop making it suitable for applications that require high flow rates.

Reduced port ball valve

Reduced port ball valve has a smaller bore diameter than the pipe's inner diameter. Due to the reduced bore diameter this design has reduced flow path. This type of valve can cause some flow restrictions and pressure drop.

V-port ball valve

These type of control valves have V shaped ball. The V shape opening in the ball allows for precise flow control and modulation making it suitable for accurate throttling of flow rate. V port ball provides linear flow characteristics which means that the flow rate is directly proportional to ball opening. This characteristic makes it easier to control the fluid flow accurately.

Floating ball valve

In a floating ball valve, the ball is not fixed in place but floats between the seats. The pressure from the fluid or gas helps create a tight seal between the ball and the seats. Floating ball valves are commonly used for low- to medium-pressure applications.

Top entry ball valve

Top entry ball valves have their ball and stem accessed from the top of the valve body. This design allows for easier maintenance and repairs, as the valve can be disassembled without removing it from the pipeline.

Side entry ball valve

Side entry ball valves have their ball and stem accessed from the side of the valve body. They are often used in larger-sized valves or applications where top entry is not feasible.

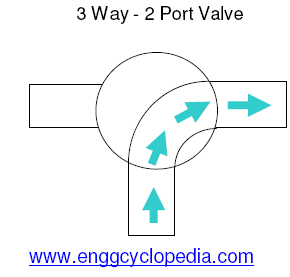

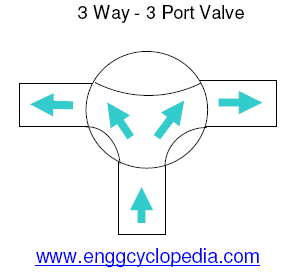

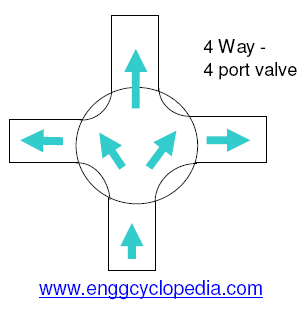

Multiport Valves

A multiport ball valve is a type of ball valve that has multiple ports or openings in the valve body, allowing for the redirection of flow in different directions. Instead of a single inlet and outlet like in a standard ball valve, a multiport ball valve has additional ports that enable various flow configurations. The different types of multiport valves are indicated in the figures below.

Advantages

- Ball valves provide a leak-tight service.

- They can be quickly opened or closed, with a small torque.

- They are smaller and lighter compared to other valves for isolation.

- Soft seated ball valves can be used for clean applications and metallic seated valves for slurry applications.

- Ball valve design is flexible with several varieties.

- Multiport ball valves offer design options not possible with other valves.

Disadvantages

- Ball valves are not very useful for throttling operations.

- Soft seated valves used in abrasive or slurry applications result in damage of the valve.

Applications of ball valves

- Shut-down and isolation valves for liquid and gaseous services needing leak tight valves.

- Emergency Shut Down valves.

- Low differential pressure control valves.

- Control and shut-down valves for steam service.

- Vent and drain valves for liquid and gaseous services.

- Pipeline surge control valves.