Spectacle Blind / 8 Blind / Line Blanks

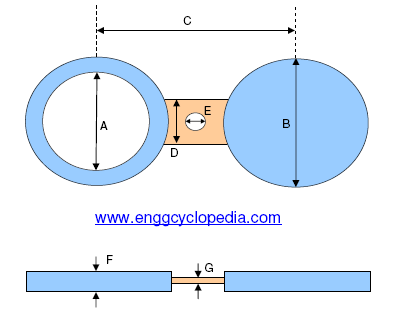

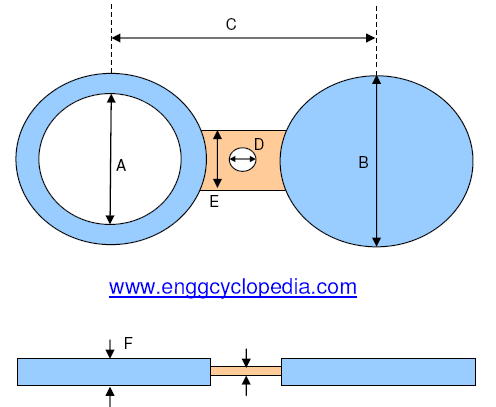

An '8 blind' or a 'spectacle blind' is a piping fitting that is used for providing positive isolation. It consists of a pair of metal discs attached to each other as shown in the figure. They are also known as 'line blanks', since they are used to blank a line.

These metal discs are cut to fit between two pipe flanges and usually sandwiched between two gaskets. One of the metal discs is solid and is used for blinding or isolating the pipe, during maintenance. The other metal disc has a circular hole to match the pipe internal diameter, as shown in the figure. The function of this disc is to allow the flow through the pipe during normal operation.

Two discs are attached to each other using a metal piece with a small hole in it which can be used for rotating the 8 blind / spectacle blind. So during normal operation the solid disc is outside the pipe and hollow disc allows the flow through the pipe. During maintenance this 8 blind is rotated so that the hollow disc is outside the pipe while solid disc blocks or isolates the fluid flow on one side of the pipe.

The name spectacle blind comes from the spectacle like appearance of the device and the name 8 blind originates from the two circular discs used to make the device. They are generally installed as a permanent device to separate process piping systems.

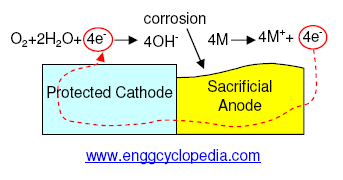

They are often used along with block and bleed valve assemblies meant to provide positive isolation for maintenance on the process facilities. After that block and bleed valve is closed and equipment is depressurized and drained, the 8 blind / spectacle blind can be rotated into close position to provide additional isolation from process fluids entering the maintenance area.

The whole idea of a spectacle blind is so that one can be absolutely sure that an item of equipment is properly and securely blanked off with no possibility of any flow or leakage through a valve during maintenance.

The flow can be diverted to other items of equipment but not just bypassed around the blank as this would compromise the safety function of the spectacle blind. The flow has to valved off and pressure relieved prior to loosening flange bolts and swinging the blind.

Standard dimensions of a spectacle blind

ASME B16.48 covers pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for operating spectacle blinds or 8 blinds in sizes NPS 1/2 through NPS 24 for installation between ASME B16.5 flanges in the 150, 300, 600, 900, 1500, and 2500 pressure classes.