Different structures of different types of valves make them suitable for a wide range of applications. For each application, some types of valves are more suitable compared to others. This post explores the selection criteria of control valves and the types of valves used for particular applications.

Table of content:

1. Selection criteria of control valve

2. Selection of valve

Selection criteria of control valve

The selection of control valves depends on various factors and considerations specific to the application requirements. Following list presents some criteria for selection of valves that are most suitable for a given application or service.

Fluid Service

The type of fluid, whether it is gas, liquid, slurry, clean, abrasive etc. determines the type of the valves to be chosen. The chemistry of the fluid service determines the material of construction to be chosen for the valve.

Pressure and Temperature Conditions

The design as wells as operating pressure and temperature conditions affect the type of valve and the material of construction to be chosen, for the given application.

Line Size

The line size is a sometimes a crucial factor in determining the valve type. For very large pipes, compact valves such as butterfly valves may be chosen at times due to the smaller size and weight, instead of gate valves. Availability of a particular type valve for the chosen line size is also an important factor, as all the types may not be available for the chosen line size.

Throttling Characteristics

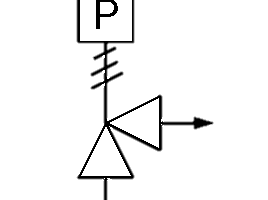

Only some types of valves offer good throttling characteristics e.g. globe valves and are preferred for the throttling and control applications.

Pressure Loss

For low pressure lines the pressure drop across the valve may be an important criterion, with a small allowable pressure drop across the valve. For example for a normally open on-off valve, a negligible pressure drop is desired across the valve when it is fully open. For such application a gate valve may be chosen as the fully open gate does not obstruct the flow path, thus causing a small pressure drop across the valve.

Special Functional Requirements

The specific function for which the valve is required may impose some special criteria for selecting the valve. For example, choosing a quick opening valve, demands special attention to ball valves.

Selection of valve

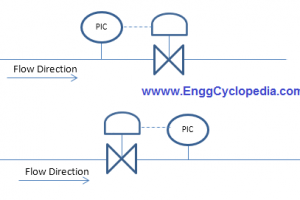

The closure member in the control valve regulates the flow by a certain mechanism. This mechanism of configuring a flow path through the valve imparts some flow characteristics to the valve. This flow characteristic of the valve is taken into account when selecting a valve for given flow regulation duty.

Valves for Stopping and Starting Flow

Slide valves, rotary valves, and flex-body valves are typically used because they have low flow resistance and a straight-through flow passage. Closing-down valves have a higher flow resistance due to their tortuous flow passage, so they are less frequently used. However, if the higher flow resistance is acceptable, closing-down valves can also be used.

Valves for Controlling Flow Rate

Closing-down valves such as globe valves are used to adjust the flow rate in such cases because the size of the seat opening is directly proportional to the travel of the closure member. Rotary valves and flex-body valves also offer good throttling control, but only over a limited range of valve openings. Gate valves, in which a circular disc travels across a circular seat opening, only achieve good flow control near the closed valve position. Therefore, they are not normally used for this duty.

Valves for Diverting Flow

Valves with three or more ports are used to divert flow in such scenarios. Plug valves and ball valves are the most common types of valves used for this purpose. However, other types of valves can also be used, such as combination valves that are made by linking two or more valves together.

Valves for Fluids with Solids in Suspension

Valves in which a closure member that slides across the seat with a wiping motion are best for fluids with suspended solids. Valves with a square-on motion can trap solids and are only suitable for clean fluids, unless the seating material can embed trapped.

Let's check selection of valves based on the fluid service to be handled.

Valves for liquid flow control

| Nature of fluid service & Mode of flow regulation | Clean & Neutral (Water, Oil, etc.) | Corrosive | Slurry | Solid suspension |

| On/ Off Control | Gate, Rotary, Plug, Diaphragm, Butterfly | Gate, Rotary, Plug, Diaphragm, Butterfly | Rotary, Plug, Diaphragm, Butterfly, pinch | Gate, Diaphragm , Pinch |

| Throttling & Diverting | Globe, Butterfly, Diaphragm | Globe, Butterfly, Diaphragm | Gate, Diaphragm, Butterfly, pinch | Gate, Diaphragm , Pinch |

Valves for gas flow control

| Nature of fluid service & Mode of flow regulation | Clean & Neutral (Air, Steam, etc.) | Corrosive | Vacuum |

| On/ Off Control | Gate, Globe, Rotary, Plug, Diaphragm | Rotary, Plug, Diaphragm, Butterfly | Gate, Globe, Rotary, Butterfly |

| Throttling & Diverting | Globe, Butterfly, Diaphragm | Globe, Butterfly, Diaphragm | - |