Foam water spray systems can be used for a combination of Class A and Class B hazards. They are mostly applicable to the protection of two-dimensional flammable liquid hazards.

Method of operation for foam water spray systems

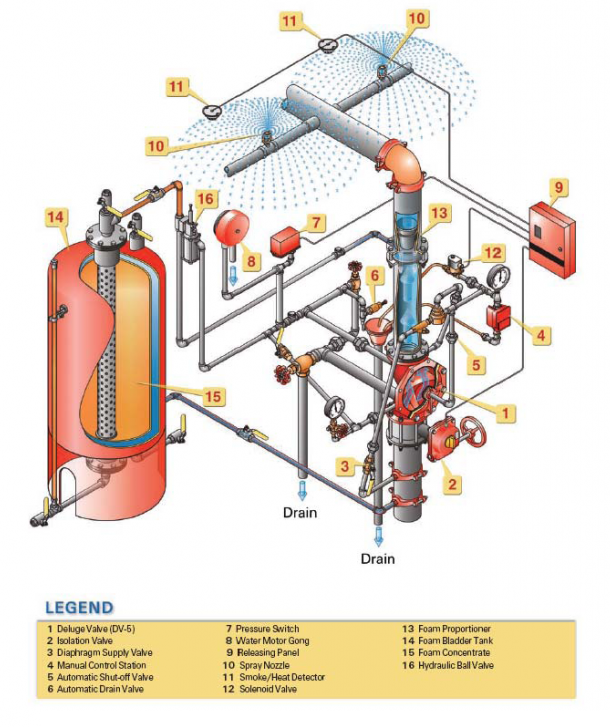

Foam water systems generally work by allowing foam concentrate to mix with water flowing into the piping system. These systems are equipped with a bladder tank containing foam. When a fire is detected a signal is sent to the releasing panel to open the deluge valve allowing water to flow. At the same time, piping to the bladder tank flows and pressurizes the outer shell of the bladder tank which forces foam concentrate to travel into the system piping and then into the Foam Proportioner. The foam solution produced by water and foam concentrate flows into the system piping and is discharged through the open nozzles or sprinklers

Foam water spray systems can be used for discharge of water first, followed by discharge of foam for a pre-determined period, and then followed by water until manual shut off.

Types of foam water spray systems

Foam water systems are generally divided into the following four (4) categories:

- Wet pipe systems

- Dry pipe systems

- Deluge systems

- Preaction systems

Definitions

Wet pipe spray systems: A sprinkler system employing automatic sprinklers or nozzles that are connected with a piping system that contains water.

Dry pipe spray systems: A sprinkler system employing automatic sprinklers or nozzles that are connected with a piping system that contains air or nitrogen under pressure, the release of which permits the water pressure to open a valve.

Deluge spray systems: A sprinkler system similar to the wet pipe spray system, with the exception of employing open discharge devices.

Preaction spray systems: A sprinkler system similar to the dry pipe spray system with the addition of a supplemental detection system installed in the same area as the sprinklers. Preaction systems are generally used in areas where damage from inadvertent operation of water spray systems must be avoided. Preaction systems generally divide into two (2) groups: single interlock preaction systems and double interlock preaction systems. Double interlock preaction systems require two independent events in order to activate. Firstly, the sprinkler piping loses air or nitrogen pressure due to the operation of one or more sprinklers, and secondly, the solenoid valve is triggered by the operation of a fire detection device.

Types of foam concentrate

Various types of foam concentrate exist, in accordance with the application considered. Typical foam concentrate types are the following:

- Aqueous Film-Forming Foam Concentrate (AFFF).

- Film-Forming Fluoroprotein Foam Concentrate (FFFP).

- Alcohol-Resistant Foam Concentrate, used for fighting fires on materials usually destructive to regular AFFF or FFFP foams as well as fires involving hydrocarbons.

- Fluoroprotein Foam Concentrate.

- Synthetic Foam Concentrate.

In general, different types and/or brands of foam concentrates shall not be mixed together.

Design considerations for foam water systems

Water supplies shall be properly designed in order to supply the system at the design discharge rate and pressure for minimum 60 minutes.

In no case shall the design discharge density be less than 0.16 gpm/ft2 (6.5 mm/m2). Bigger densities can be used depending on the type of fire as well as the recommendations of foam manufacturer.

Taking into consideration this minimum density, the foam solution shall be designed to discharge for a period of 10 minutes over the entire system's area for deluge and spray foam-water systems and over the design area (design area is equal to 465 square meters in accordance with Paragraph 7.3.7.1 of NFPA 16) for wet pipe, dry pipe, and preaction foam-water systems. In case discharge density is higher than the minimum stipulated [0.16 gpm/ft2 (6.5 mm/m2)], then a reduction in the duration of foam discharge time many be allowed, but in no case shall the duration be less than 7 minutes.

Whenever occupancy standards dictate a design area different than 465 square meters, then the occupancy standards shall take precedence.

Sprinkler spacing shall not exceed 100 square feet (9.3 square meters) per sprinkler or exceed 12 ft (3.7 m)

spacing between sprinklers installed at a branch line or between branch lines.

Whenever sprinklers are installed on the roof or the ceiling, their temperature rating shall be within the range of 121 degrees Celsius to 149 degrees Celsius. Whenever installed at a lower level, their temperature rating shall range between 57 degrees Celsius and 77 degrees Celsius.