When atmospheric or low pressure storage tanks are exposed to fire, the liquids vaporise and vapour at high temperature leads to pressure building up of pressure in the tank. Hence, this overpressure needs to be relieved to protect the mechanical integrity of the tank. The tank venting requirement for different types of storage tanks are given in the standard API 2000. These venting requirements are likely to exceed the normal venting requirement for liquid movement and thermal effects.

Some low pressure storage tanks are equipped with a frangible roof top which has a weak roof to shell attachment. In case the emergency venting requirement should exceed the capacity of normal venting outlets, resulting in overpressure, this weak attachment fails prior to any other joints in the tank structure. Thus an opening is created to relieve the overpressure from the tank. For such tanks no additional measures have to be taken for emergency venting.

For other tanks, the emergency tank venting requirement can be calculated using the procedures from API 2000.

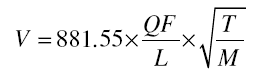

V: Emergency tank venting requirement in Nm3/hr

Q: Heat input from fire in Watts

F: Environmental factor

L: Latent heat of vaporization for the stored contents in kJ/kg

T: Temperature of relieving vapor in Kelvin

M: Molecular weight of vapor in gm/mole

The heat input from fire depends on the wetted surface area of the tank and can be estimated as a function of the wetted area as per following table from the API 2000.

| Wetted tank surface area (m2) | Heat input (Watts) |

| < 18.6 | 63,150×A |

| ≥ 18.6 and < 93 | 224,200×A0.566 |

| ≥ 93 and < 260 | 630,400×A0.338 |

| ≥ 260 with design pressure between 0.07 and 1.034 barg | 43,200×A0.82 |

| ≥ 260 | 4,129,700 |

For cases where a lesser degree of accuracy can be tolerated, following equations from API 2000 can be used.

V = 208.2FA0.82

Q = 43,200A0.82

V: Emergency tank venting requirement in Nm3/hr

F: Environmental factor

Q: Heat input from fire in Watts

A: Wetted tank surface area in m2

The environmental factor F depends on multiple factors such as, tank type, confuguration, insulation conductivity, and insulation thickness. This environmental factor F can be read from API 2000, and credit can be taken for only one environmental factor.

When the emergency venting requirements are estimated, first they are compared to the normal venting capacity of the system. During fire thermal effcts for venting can be ignored and liquid movement can be assumed to be stopped in case of fire. Hence if normal venting capacity is able to handle the emergency venting requirement, full credit can be taken for this capacity.

If the emergency venting requirements exceed the normal venting capacity, then additional venting arrangements have to be made to take care of emergency tank venting during exposure to fire.