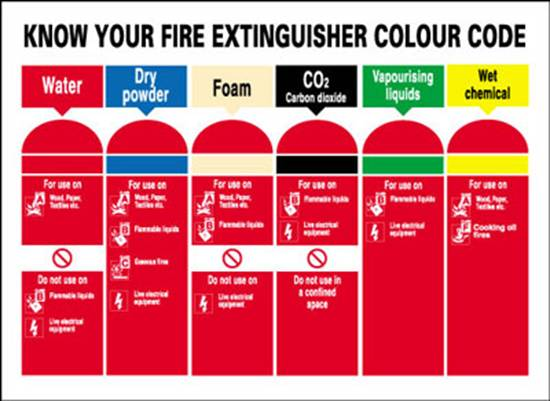

Fire extinguishing agents covered by NFPA 2010 shall be electrically non-conductive.

By definition, aerosol is a fire extinguishing medium consisting of finely divided particles, whose diameter is typically less than 10 microns.

Available technologies for aerosol-based fire fighting

There are generally two (2) technologies based on type of aerosol used:

Condensed aerosol for fighting

Condensed aerosols are typically generated through a combustion process of a specific aesosol-forming solid compound. In these systems, the device used for creating this pyrotechnical reaction is usually called 'aerosol generator'. The generator, started up by an igniter, which is triggered typically thermally or electrically, releases an exothermic chemical reaction generating a gas discharge containing solid particles, typically composed of potassium salts (e.g. K2CO3), H2O, N2, CO2 and inert gas.

Dispersed aerosol for fire fighting

On the other hand, dispersed aerosols basically consist of extinguishing powder which is diffused by a carrier gas, either halogenated or inert.

Out of the 2 types, condensed type aerosols are the ones mostly in use. Different-sized generators are available, thereby protecting different volumes.

How fire is extinguished using aerosols

The tiny dimensions of the salts (typically potassium) particles (a few microns of diameter) transported by inert gas give the generated aerosol the power to flow round the obstacles, to penetrate the volumes and get a uniform spread in the protected volume. When aerosol hits the flames, potassium salts (K2CO3) are dissociated, forming potassium radicals (K+). Free radicals K+ bind with free radicals OH that fuel the combustion, forming stable compounds (KOH), thus interfering with the combustive reaction: free OH radicals are no more available to fuel combustion). Consequently, the fire is extinguished.

Use of aerosols for fire fighting

Aerosols are mostly effective on Class B fires, i.e. fires involving flammable-combustible liquids, petroleum greases, oils, oil-based paints, solvents and flammable gases. However, they can also be safely used at Class A (deep-seated fires excluded) and Class C fires.

Aerosol fire fighting systems shall not be used for putting out fires involving the following materials:

- deep-seated fires in Class A materials (wood, paper, fabric etc),

- certain chemicals of mixtures of chemicals like cellulose nitrate, gunpowder, hydrazine, some organic peroxides,

- metal hydrides,

- reactive metals like lithium, sodium, potassium, magnesium, titanium, zirconium, uranium and plutonium,

The above list is definitely not exhaustive. Fires involing the presence of sodium chlorate, sodium nitrate, nitric oxides, fluorine etc have also been reported not to be fought with aerosols.

When in doubt, user must consult the aerosol manufacturer as well as the Authority Having Jurisdiction (AHJ) .

Safety considerations

Unless the generators are specifically listed for use in those environments, condensed aerosol generators are not to be used to protect classified hazards or spaces containing flammable liquids or dusts that may be present in explosive air–fuel mixtures.

The minimum safety distances specified in the listing of the aerosol generator must always be respected.

The minimum safety distance between the condensed aerosol generator discharge ports and personnel shall be based on an aerosol agent discharge temperature, at that distance, not exceeding 75°C.

On the other hand, the minimum safety distance between the condensed aerosol generator discharge ports and combustible materials shall be based on an aerosol agent discharge temperature, at that distance, not exceeding 200°C.

Predischarge alarm and time delay shall be provided as a means to prevent human exposure to aerosol agents.

In the event of failure of predischarge alarm and time delay, personnel exposure to agents approved for use in normally occupied spaces shall not exceed 5 minutes.

Alarms, indicators or both shall be used to indicate the operation of the system, hazards to personnel, or failure of any supervisory device. Abort switches may also be used, located within the protected area, near its entrance. However, the manual emergency control shall override the abort function.

Aerosol fire fighting system design

The necessary quantity of aerosol-forming compound is calculated from the formula below:

m = d×f×V,

where:

m= the total flooding quantity (in g)

d = the design application density (in g/cubic meter): design application density is calculated by proper testing for the specified Class A, B or C fuel.

f = additional design factors, detailed in Paragraph 7.5.2 of NFPA 2010

V= the protected volume (in cubic meters)

Additional design factors take into consideration the following: tee design factor, unclosable openings, height of protected volume, danger of re-ignition from hot surfaces, enclosure geometry restrictions and obstructions, ambient pressure that varies more than 11% from standard ambient pressure at sea water level etc.

However, with the exception of tee design factor, NFPA 2010 does not give any instructions for quantifying these design factors.

Where a single agent is used for protection of multiple hazards, the tee design factor takes values from 1.00 to 1.12, depending on the number of pipe tees in the flowpath of the agent supply.

Aerosol discharge time requirement

The necessary discharge time for achieving 95% of the design application density shall not exceed:

- 60 seconds or as otherwise stipulated by the AHJ for condensed aerosol systems.

- 10 seconds or as otherwise stipulated by the AHJ for dispersed aerosol systems using halocarbon agents.

- 60 seconds (including a 30% safety factor) or as otherwise stipulated by the AHJ for dispersed aerosol systems using inert gas.