Why have been limits imposed on the frequency ratio for thermowells?

In 1995, an accident caused due to breaking thermowells in Monju Nuclear Plant reactor, led to very serious damages to the surrounding facilities. Thermowells located on a line carrying liquid sodium coolant were subjected to intense vibration and eventually broken. As a result 3 tons of sodium coolant leaked out of the pipes. When contacted with the air, the liquid sodium spontaneously reacted with oxygen and moisture in the air, filling the room with sodium fumes and producing temperature of several hundred degrees Celsius. Intense heat generated damaged several steel structures in the room. The investigations after the accident pointed towards the thermowell damage being the root cause and this accident led to the development of Performance Test Codes (PTC) 19.3 (2010) to be followed by the thermowell manufacturers. These codes impose maximum limitations on the vibration frequencies for the thermowells.

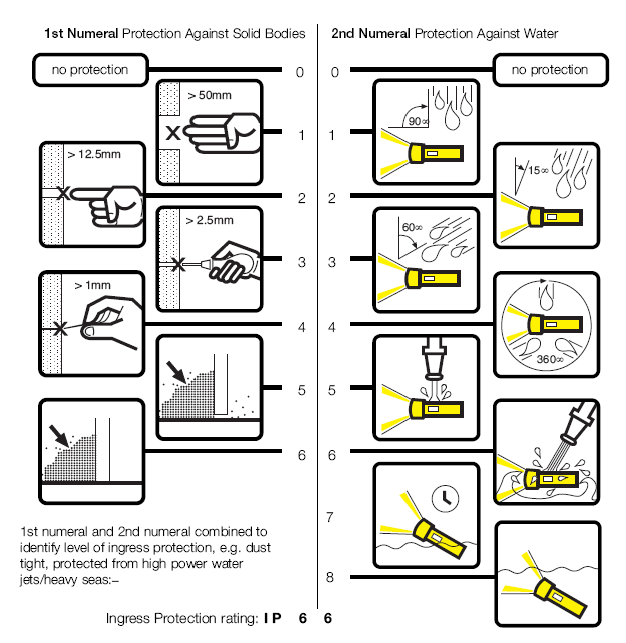

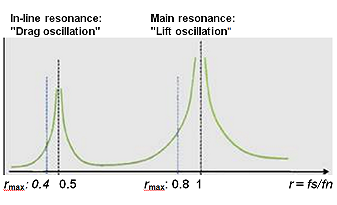

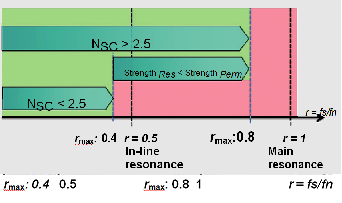

ASME PTC 19.3 TW-2010 is divided into dynamic and static calculation results. For gaseous media, the previous limit frequency, r max = 0.8, from PTC 19.3-1974, is still valid. For liquid media, in many applications, the newly-introduced limit frequency of r max = 0.4, applicable for the inline resonance. The evaluation of the dynamic results is made using the damping factor NSC. For gaseous media, a characteristic value is NSC > 2.5; fluids typically have an NSC < 2.5.

ASME PTC 19.3 TW-2010 is divided into dynamic and static calculation results. For gaseous media, the previous limit frequency, r max = 0.8, from PTC 19.3-1974, is still valid. For liquid media, in many applications, the newly-introduced limit frequency of r max = 0.4, applicable for the inline resonance. The evaluation of the dynamic results is made using the damping factor NSC. For gaseous media, a characteristic value is NSC > 2.5; fluids typically have an NSC < 2.5.

Whether frequency ratio r < 0.8, can also be used as an evaluation limit with liquid process media, is determined through a consideration of the permissible stresses in the thermowell material with respect to the actual stresses at resonance. In addition, an evaluation of the strength of thermowell material with respect to flexural fatigue stress in area of thermowell clamping is carried out. The results of static analysis as per ASME PTC 19.3 TW-2010 are generated from the maximum permissible process pressure (dependent upon the process temperature and the geometry of the thermowell) and the bending stress in the area of thermowell root. Bending stresses are caused by the incident flow on the thermowell, and is dependent on the shielded length of the flange adapter.

For fabricated thermowells, the calculation method per Dittrich/Klotter must be used because this construction is not covered by ASME PTC 19.3 TW-2010.The approach is based on calculating the stresses occurring under load. These are compared with allowable stresses for the thermowell and safety factors.

Remedies using structural changes, when r max (permissible), is exceeded

By exceeding the maximum permissible limit frequency, r max, for the "In-line"- or main resonance, following structural changes should be made:

a) Shortening of insertion length

This is the most effective method (and the recommended method from ASME PTC 19.3 TW-2010) for improvement of frequency ratio r.

b) Increasing the tip diameter

b) Increasing the tip diameter

By the enlargement of the tip diameter, natural frequency fs is reduced, as well as the frequency ratio r is optimized.

c) Support through an anchor

Support of the thermowell through an anchor is generally not recommended by ASME PTC 19.3 TW-2010, and lies outside the scope of the ASME code. On customer request, an anchor can be used, in line with precise customer specifications and the process side thermowell components below the anchor connection will be designed in accordance with the design and calculation criteria of ASME PTC 19.3 TW-2010, without, however, falling within the scope of ASME PTC 19.3 TW-2010. The operator is responsible for the rigid support of the anchor in the adapter, which may mean that a reworking of the adapter is needed.