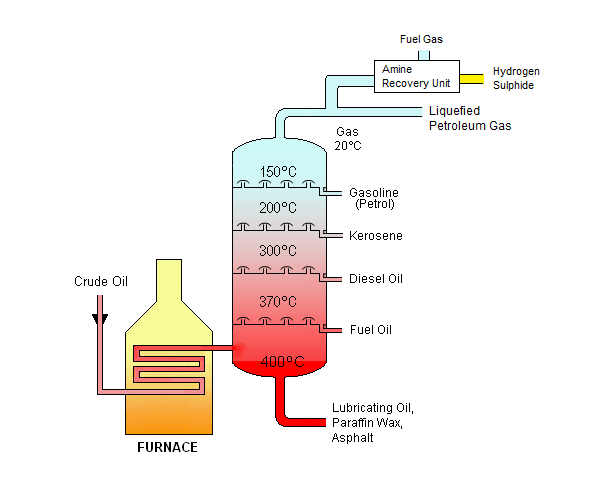

Crude oil is first refined in an Atmospheric Distillation Column. Fractions of crude oil such as lighter gases (C1-C4), gasoline, naphtha, kerosene, fuel oil, diesel etc. are separated in the atmospheric distillation column. The after taking out these lighter hydrocarbon cuts, heavy residue remaining at the bottom of the atmospheric distillation column needs to be refined. These heavy hydrocarbon residues are sent to a Vacuum Distillation Column for further separation of hydrocarbons under reduced pressure.

Heavies from the atmospheric distillation column are heated to approximately 400˚C in a fired heater and fed to the vacuum distillation column where they are fractionated into light gas oil, heavy gas oil and vacuum reside. Some heavy hydrocarbons cannot be boiled at the operating temperature and pressure conditions in the atmospheric distillation column. Hence they exit the bottom of the column in liquid state and are sent to the vacuum distillation column where they can be boiled at a lower temperature when pressure is significantly reduced. Absolute operating pressure in a Vacuum Tower can be reduced to 20 mm of Hg or less (atmospheric pressure is 760 mm Hg). In addition, superheated steam is injected with the feed and in the tower bottom to reduce hydrocarbon partial pressure to 10 mm of mercury or less. Lower partial pressure of the hydrocarbons makes it even more easier for them to be vaporized, thus consuming less heat energy for the process.

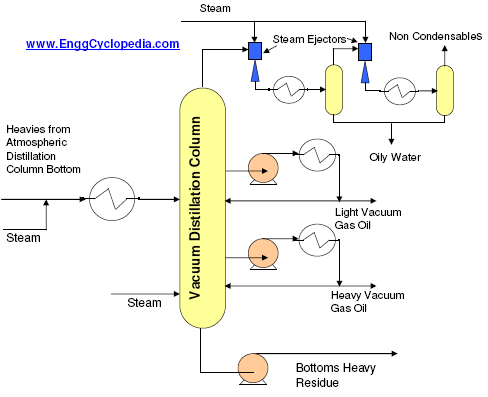

A typical process flow diagram (PFD) of such a vacuum distillation column is presented in the figure above. Steam ejectors can be used to suck the lighter hydrocarbon vapors at low pressure from the top of the column. These vapors are then cooled down to condense the steam which had been introduced in the column earlier. The condensed oily water is removed and can be recycled to the column after boiling it. Hydrocarbon vapors are taken out at this stage.

Two different cuts of hydrocarbons - 'light vacuum gas oil' and 'heavy vacuum gas oil' are separated in the vacuum distillation column at different stages of the column, based on the difference between their boiling point ranges. The liquid being drawn at low pressure needs to be pumped. Then it is heated and partially recycled back to the column. Part of is is taken out as vacuum distillation products - 'light vacuum gas oil' or 'heavy vacuum gas oil'. Light vacuum gas Oil is sent to a hydrotreater and then to a 'catalytic cracking' unit to obtain smaller chain hydrocarbons. Heavy vacuum gas oil is also sent for cracking using hydrogen in a 'hydrocracking unit' to produce smaller chain hydrocarbons.

Heavy hydrocarbons which cannot be boiled even under reduced pressure remain at the bottom of the column and are pumped out as 'vacuum residue'. The vacuum distillation column bottom residue can only be used for producing coke in a 'coker unit' or to produce bitumen.