Superheated steam is basically a state of steam of type of steam, having zero water content and having temperature above the boiling point of water at the given pressure.

How is superheated steam generated?

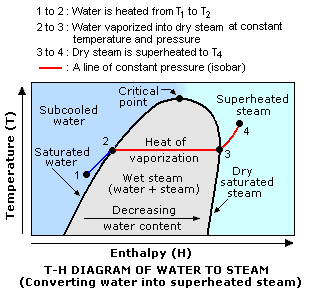

- When the water is heated up, its temperature increased till its reaches the boiling point. Up to this point, all the heat supplied to the water is used for rise in temperature. This is indicated by water going from point 1 to point 2 in the T-H diagram above.

- At boiling point, water starts to vaporize and all the newly added heat is used for this phase change. This is represented by the path from point 2-3. During this part there is increase in temperature, as all the added heat is utilized for phase change. Temperature stays at the boiling point.

- When all of the water is boiled off (point3), the heat added next to this dry steam is used for raising its temperature above the boiling point. This additional heat that raises the steam temperature is the 'superheat' added to the steam. And the excess temperature of the steam above the boiling point is - 'degree of superheat'.

Boilers are used in the industry to generate superheated steam from water. This superheated steam is generally preferred whenever you want to avoid two phase flow in the steam network pipes.

Superheated steam properties

- Superheated steam temperature is often significantly above the boiling point at give pressure. The excess temperature above the boiling point is known as 'degree of superheat'.

- Superheated steam has zero water content. Hence 100% steam quality.

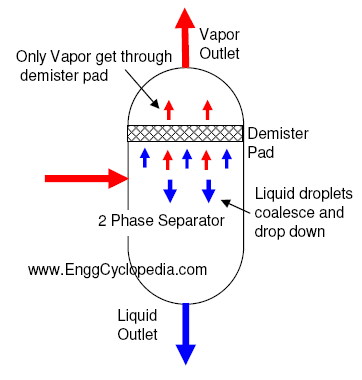

- You can maintain the superheated steam pipes to have single phase flow. This way many problems associated with two phase flow can be avoided, for example - slugging, steam hammering, noise, erosion, vibrations etc.

Desuperheated steam

Some processes require the steam as a utility at the saturation point or slightly above. We can call this 'nearly saturated' dry steam. This is especially important for heat transfer operations. Since condensing steam can give up a lot more heat without any drop in its temperature.

For this purpose, it is sometimes desirable to 'desuperheat' the steam using a desuperheater equipment in the steam pipe. It works by spraying some cold water in the steam flow, just enough to cool it down slightly above the saturation point. Normally the desuperheated steam is kept at 3 deg C above the saturation point.

There are 2 types of steam desuperheaters - (i) indirect contact type and (ii) direct contact type.

Steam tables

Steam tables are used as reference source to calculate different properties of steam as a function of its temperature and pressure. A variety of properties of superheated steam can also be quickly referred to using the steam tables - such as, specific volume, density, viscosity, enthalpy, entropy etc.

Using steam tables for superheated steam at corresponding temperature and pressure values, is a quick way to get reasonably accurate values of steam properties, at given T & P.