Slug catcher is a static equipment used in the upstream oil production facilities to minimize the slug from oil and gas pipeline. Fluids extracted from oil and gas reservoirs contain crude oil, natural gas, water, salts etc. The multiphase flow in a pipeline often leads to formation of slug flow. This multiphase flow is received in a large vessel in the crude oil processing and storage facilities where the oil, water and gases are crudely separated to remove the slug, hence the name.

Table of content:

1. Slug flow

2. How does a slug catcher works?

3. Types of slug catchers

3.1. Vessel type slug catchers

3.2. Finger type slug catchers

3.3. Parking loop slug catchers

Slug flow

A multiphase flow is type of flow that contains two or more phases such as liquid, gas and solid. A multiphase flow in a pipe or pipeline sometimes results in a slug flow where the fluid gets segregated into plugs of liquids and gases flowing after one another in the same pipeline. These plugs of liquids and gases are called slugs.

Slug flow can be formed in a pipeline due to a variety of reasons such as

- Terrain ups and downs: Elevation in pipeline occur due to ground elevation or sea bed. When the pipeline faces terrain ups and downs, the different phases of fluids can separate due to gravity.

- Higher gas velocity compared to liquid velocity: If the gas flows faster than liquid, it can push liquid ahead of it that results in slug formation.

- Pigging: Pigging is a process of cleaning pipe by sending pig through it. If the pig is not inserted into the pipeline properly or not inserted smoothly, pig can cause slug flow.

When liquid slugs arrive in an onshore oil processing facility, the liquid flowrate is significantly higher than the normally anticipated liquid flow for which the processing equipments are designed. This can cause problems such as:

- Equipment damage: The high flow rate of liquid can cause equipment to vibrate or even break.

- Product contamination: The slugs of liquid may contain dirt, sand or other contaminants that can contaminate product.

- Loss of production: The equipment damage or product contamination may result in loss of production due to plant shutdown.

Hence to avoid such problems, a buffer volume is needed to convert the slugs of oil and water into steady liquid flow going to the oil processing facilities. This buffer volume is provided by the slug catchers.

Slug catchers are devices installed in a pipeline to smooth out the flow of multiphase fluid. It removes the slugs by providing a large volume of buffer space for slugs to collect. The slugs slowly drain out of the slug catcher and provide a steady flow of fluid.

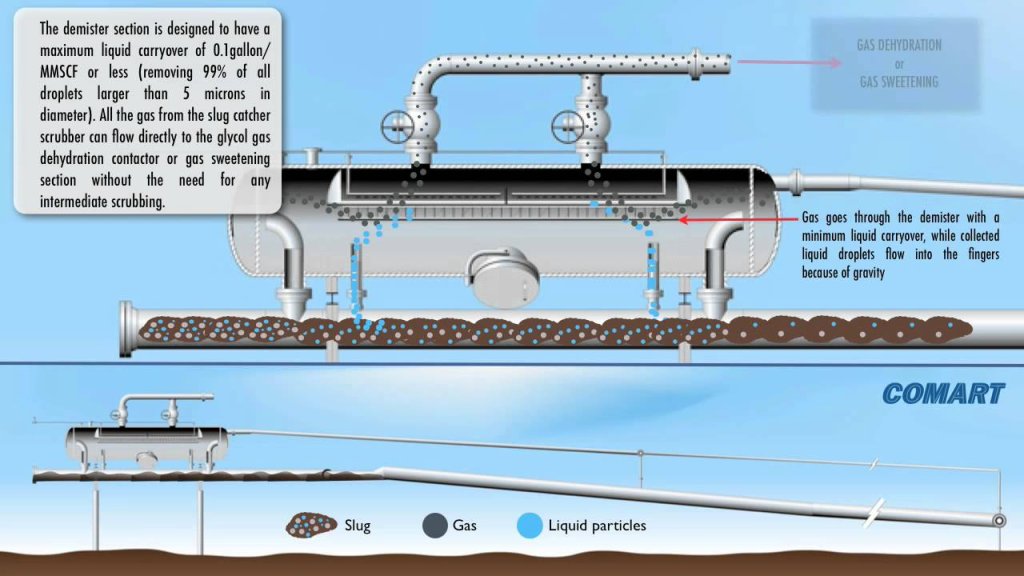

How does a slug catcher works?

The working mechanism of the slug catcher is described in this section.

- A slug of fluid enters the slug catcher.

- A slug catcher provides a buffer volume to accommodate the intermittent high liquid flow in the form of a slug. This means that slug catcher has a large enough volume to store the slugs of liquid.

- Slug performs a very crude gas liquid separation. Slug catcher does not completely separate the gas and liquid phase. It remove enough gas so that liquid can be drained more easily.

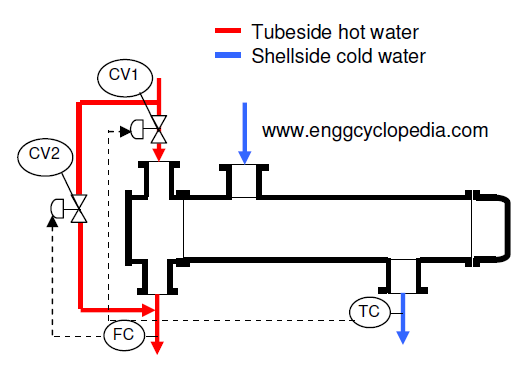

- The liquids in the vessel can then be slowly drained to the downstream processing facilities at their design flow.

Slug catchers are often equipped with instrumentation to monitor the liquid level in the vessel and liquid flow to the downstream facilities.

Types of slug catchers

Vessel type slug catchers

Vessel type slug catcher is a simple two phase separation vessel. While the separation efficiency of the vessel is not critical for a slug catcher, the vessel volume is. The vessel needs to be large enough to accommodate large liquid slugs produced by a pipeline, especially during pipeline pigging. Since a oil and gas pipeline usually sees a very high pressure the large vessel has to be designed to withstand a high design pressure as well.

Finger type slug catchers

Finger type slug catcher provides an answer to the economic problem of having to design a large buffer vessel at high design pressure. Finger type slug catchers use pieces of large diameter pipes instead of a conventional vessel to provide a buffer volume. Since pipe is easier to be designed to withstand high pressure compared to a vessel, this design is advantageous in that respect. However, large number of pipes is required to provide sufficient volume and this results in a large footprint for the slug catcher.

Parking loop slug catchers

Parking Loop slug catcher combines features of the vessel and finger type slug catchers. A vessel is used for basic gas liquid separation, while the liquid buffer volume is provided by parking loop shaped fingers. From these fingers the liquid is slowly drained to the downstream processing equipment.