Instrument air is made available to the instrument air headers by compressing the atmospheric air. The compressed air being used for instruments is needed to be dry to a certain extent, whereas ambient air usually comes with moisture. When the moist air is compressed, some of the water content tends to condense under pressure and is removed using knock out drums at the discharge of instrument air compressors. The air coming out of knock out drums is still somewhat moist and further drying of this air is carried out by using Instrument Air Dryer and Filter System.

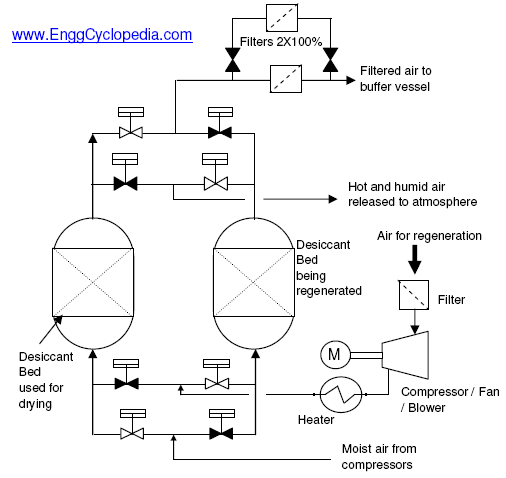

Typically instrument air dryer and filter systems consist of two parallel vessels with instrument air drying beds. When moist air is passed through such a dryer, moisture from the air gets absorbed by this bed and dry, dehumidified air is passed through the outlet. The dried air is filtered to remove any particulate matter, possibly entrained from the dryer bed.

When a dryer bed absorbs moisture from wet air, after some time it gets saturated and cannot absorb any more moisture. Hence it is needed to remove all the moisture content from this dryer bed, to regenerate it. This regeneration is carried out by passing hot air through the dyer, thus heating up the dryer bed to free the moisture. Due to high temperature of the regenerating air, it can accommodate higher moisture content. Hence the bed is dried by hot regeneration air and moisture is carried out to the atmosphere by this hot stream of humid air.

To regenerate a dehumidifier bed, without interrupting the dryer operation, two dryer vessels are used in parallel as indicated in figure-1. While one vessel dehumidifies the wet air from compressor, the other dryer bed is regenerated by heating using hot air. Atmospheric air is used for dryer regeneration. A fan or blower is used to send atmospheric air to a heater which heats up the atmospheric air. The hot air is then passed through a dryer bed to remove moisture from the bed. Moist air from the dryer bed is released to atmosphere, using an on-off valve. When one dryer bed becomes saturated with moisture, on-off sequence valves are used to switch the drying operation is easily to the other bed which has been dried by hot air.