Multiphase flow meter (MPFM) plays a vital role in the oil production industry by enabling accurate and efficient measurement of flow rates for crude oil, water, and gas. Their ability to provide real-time data, optimize production, and reduce costs makes them indispensable tools for operators seeking to enhance their reservoir management practices.

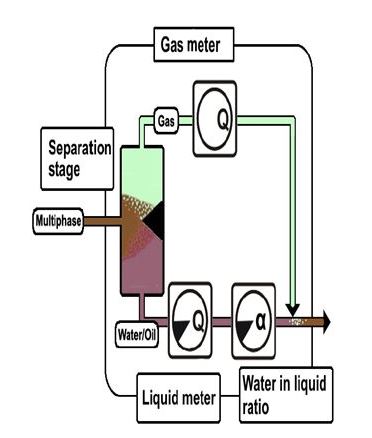

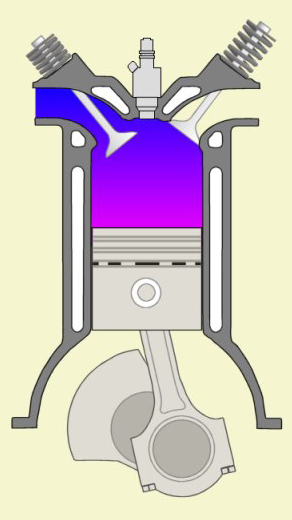

A multiphase flow meter is used to measure the flow rates of multiple phases, such as crude oil, water, and gas, in an oil production well. It is designed to handle the complex mixture of fluids that come from the well and provide accurate measurements of each phase's flow rate. A multiphase flowmeter can be thought of as a scaled down assembly of test separator and corresponding flow meters.

The multiphase flow meter is typically installed on the test header or manifold from an oil well, which is a separate small header parallel to the main production header. The purpose of the test header is to allow for the measurement of flow rates of oil, gas, and water produced from the well without interrupting the main production flow.

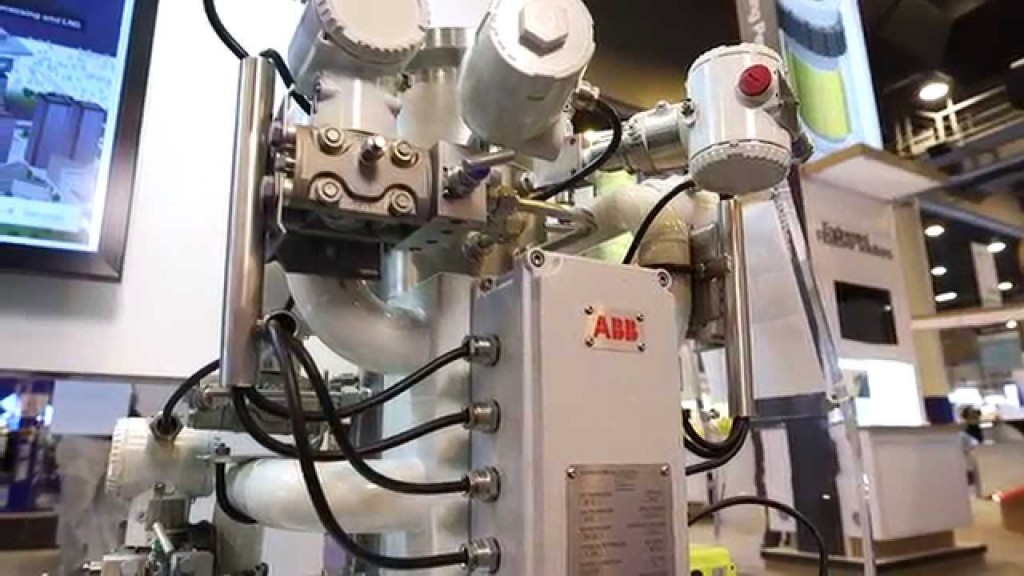

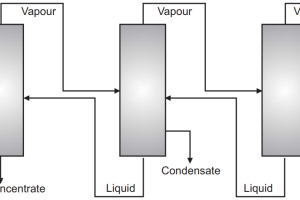

The multiphase flow meter skid, or assembly, consists of several components. It includes a small separator that helps separate the incoming multiphase fluid into its constituent phases (oil, water, and gas). Once separated, each phase is directed to individual flow meters that are specifically designed to measure the flow rate of that particular phase accurately. These flow meters can be different types, such as positive displacement meters, turbine meters, or ultrasonic meters, depending on the requirements and characteristics of the fluid being measured.

After measuring the flow rates of each phase, the individual streams are then recombined or mixed to regenerate the original multiphase stream. This allows for the calculation of the overall flow rate and composition of the produced fluids from the well.

The use of a multiphase flow meter provides several advantages in oil production, including real-time monitoring of the individual phase flow rates, improved production optimization, reduced operational costs, and enhanced reservoir management.

Benefits and Applications:

- Real-time Monitoring: Multiphase flow meters provide real-time data on the flow rates of each phase, allowing operators to make informed decisions promptly. This enables timely adjustments and optimizations for improved production efficiency.

- Enhanced Production Optimization: With precise measurements of individual flow rates, multiphase flow meters facilitate efficient reservoir management. Operators gain insights into the behavior and characteristics of the well, enabling them to fine-tune production strategies and maximize output.

- Cost Savings: By eliminating the need for conventional test separators and multiple flow meters, multiphase flow meters offer significant cost savings in terms of equipment, installation, and maintenance. Additionally, their compact design reduces footprint requirements.

- Versatility: These flow meters are designed to handle the complex mixtures of oil, water, and gas commonly encountered in oil wells. They can adapt to varying flow regimes, making them suitable for different well types and conditions.