A reducer (or an expander) is a pipe fitting used to join to pipes of different sizes.

If the upstream pipe is larger, then the tapering pipe leading to the smaller downstream pipe is called a reducer. Because, in this case the flow goes to a reduced passage.

When the upstream pipe is smaller, the tapering pipe is called an expander. As in this case the flow goes to an expanded pipe.

Table of content:

Piping reducer types - concentric & eccentric

Difference between eccentric and concentric reducer

Codes and standards for piping reducers (and expanders)

Standard reducer dimensions

Pressure drop across pipe reducers

Piping reducer equivalent length

When to use concentric and eccentric reducers

Piping reducer types - concentric & eccentric

There are only 2 main types of reducer / expander joints - concentric and eccentric. Their names are quite self explanatory.

Concentric reducers are quite common and used very widely in process piping. But when you install concentric reducers horizontally, there is a possibility of creation of air or vapor pockets in the upper part.

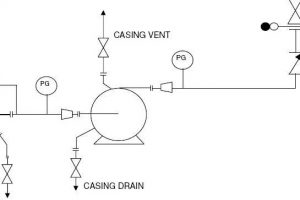

Reducers and expanders are used extensively in the inlet/outlet piping of pumps. In fact they are used for connecting many equipment to the process piping, since equipment nozzles are generally smaller.

If you install a concentric reducer in the suction piping of a centrifugal pump, you run the risk of pump cavitation. For this reason, eccentric reducers are preferred over concentric ones in centrifugal pump suction piping.

Difference between eccentric and concentric reducer

The main difference between eccentric and concentric reducer is the way they are designed to transition the flow of fluid from one pipe to another.

A concentric reducer is cone-shaped and maintains the centerline of the pipe, gradually decreasing in diameter towards both ends to provide a smooth and gradual transition of fluid flow from a larger pipe to a smaller one. It is typically used in vertical pipe runs or situations where fluid flow needs to remain centered.

On the other hand, an eccentric reducer is asymmetrical, with one end of the fitting offset from the other, creating an off-center transition that can prevent air or gas accumulation in horizontal pipe runs. It is typically used in horizontal pipe runs or situations where fluid flow needs to be redirected to one side.

The choice between eccentric and concentric reducers depends on the specific needs of the piping system and fluid flow requirements.

Codes and standards for piping reducers (and expanders)

The design, manufacturing, installation and maintenance of different piping fittings is governed by ASME/ANSI standards.

For piping reducers, you can refer to the following 2 standards,

B16.1 (2005) - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250

This Standard covers Classes 25, 125, and 250 Gray Iron Pipe Flanges and Flanged Fittings. It includes: (a) pressure-temperature ratings; (b) sizes and method of designating openings of reducing fittings; (c) markings; (d) materials; (e) dimensions and tolerances; (f) bolting and gaskets; (g) pressure testing.

B16.5 (2009) – Pipe flanges and flanged fittings (2009)

This standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, testing and methods of designating for pipe flanges and flanged fittings

Standard reducer dimensions

Standard dimensions for piping reducers and expanders as per ASME/ANSI standards are tabulated here.

Instead, you can also use this calculator to quickly determine the standard reducer dimensions for a given size.

Pressure drop across pipe reducers

Frictional pressure drop across a straight length of a pipe is generally calculated using the Darcy's equation.

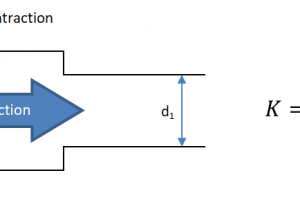

But pipe fittings add more disturbance in the fluid flow and cause additional frictional losses. We can account for these additional frictional losses by using the concept of K factor or K value for a reducer.

This K factor or K value for a reducer is the indicator of the additional frictional head loss created. There are multiple ways of estimating the K factor for reducers, before you calculate the overall frictional pressure loss across a pipe run.

If the K factor is directly multiplied by (ρv2/g), that directly gives the additional pressure drop across corresponding fittings.

Piping reducer equivalent length

You can use the K factor discussed above to calculate the equivalent length of a reducer.

Equivalent length, Leq = K × (D/4f)

where, K is the K value for a fitting (or for all fittings combined)

D is the pipe diameter

f is the Fanning friction factor

You can then add this equivalent length to the straight run pipe length. Then use that total length in Darcy's equation or in this pipe pressure drop calculator to calculate the pressure loss across a piping system.

When to use concentric and eccentric reducers

The choice between using a concentric or eccentric reducer depends on the specific application and the requirements of the piping system. Here are some guidelines:

Concentric Reducers: concentric reducers are used when an even or constant flow rate is required and when height restrictions are not a concern

- Used when there is a need to maintain an even or constant flow rate throughout the piping system.

- Ideal for vertical pipes, where the reduction in size occurs gradually and evenly, without causing a buildup of fluid pressure.

- Typically used in applications where there are no height restrictions.

Eccentric Reducers: Eccentric reducers are used when the accumulation of air, gas, or solids needs to be prevented and when height restrictions are a concern.

- Used when there is a need to prevent accumulation of air, gas or solids in the piping system.

- Ideal for horizontal pipes, where the reduction in size causes a change in the centerline of the pipe, creating a low point that allows air, gas, or solids to be drained from the system.

- Typically used in applications where height restrictions are a concern, as they allow for a lower profile installation.