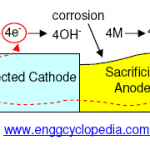

Cathodic Protection - Cathodic protection is a method of protecting a piping system or an equipment against corrosion by making the protected system cathodic. This is achieved by attaching a sacrificial anode or a galvanic anode to the protected system, thus making the protected system cathodic.

Cathodic Protection - Cathodic protection is a method of protecting a piping system or an equipment against corrosion by making the protected system cathodic. This is achieved by attaching a sacrificial anode or a galvanic anode to the protected system, thus making the protected system cathodic.

Galvanic Corrosion - Galvanic corrosion can occur in piping and equipment systems when two dissimilar metals are joined together. Galvanic corrosion occurs due to an electrochemical process in which one metal corrodes preferentially to another.

Gas Blowby - Gas blowby is an undesirable operation scenario for pressure vessels handling gas and liquid phase flows, often two phase separator vessels. In case of a gas blowby, the liquid is completely drained from the vessel thus gas flow from the pressure vessel can freely flow to the downstream equipments which are designed to handle liquid. This may result into overpressure in the downstream equipments.

Gas Blowdown - The term gas blow down is referred to venting of gas accumulated in equipments, process facilities, oil production wells etc. The gas which is to be blown down is not desired to be used for production of a variety of possible reasons and is usually vented through a flare. The flare burns the hydrocarbons before venting product gases to atmosphere.

Mothballing - Nitrogen mothballing is a maintenance procedure used for equipments to prevent corrosion of the equipments during their idle time. The basic principle is to fill up idle equipments with an inter gas, commonly nitrogen, so as to remove air, oxygen, moisture etc. to prevent these elements from corroding the equipment walls.

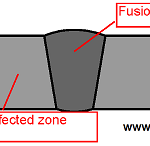

Preheating & Welding - Welding is basically the mixing of a base metal with filler metal. Filler material is melted at high temperature through a consumable electrode and provides the relevant bonding strength. Preheating is a process performed before welding. It consists of gradually increasing the temperature of the filler metal. This way, thermal gradients-stresses are kept to a minimum and suitable mechanical properties and metallurgical structure can be established.

Preheating & Welding - Welding is basically the mixing of a base metal with filler metal. Filler material is melted at high temperature through a consumable electrode and provides the relevant bonding strength. Preheating is a process performed before welding. It consists of gradually increasing the temperature of the filler metal. This way, thermal gradients-stresses are kept to a minimum and suitable mechanical properties and metallurgical structure can be established.

Add Comment