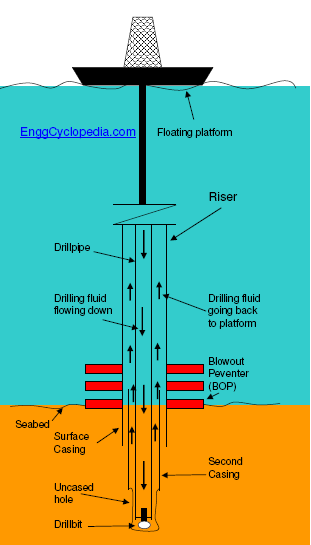

The drilling riser is very important component in offshore drilling operations. Its role is to connect the drilling vessel or platform to wellhead. These offshore risers enable the transfer of drilling fluid such as crude oil between the surface and wellbore. In this post use of these offshore risers is explored along with different types of it.

Table of content:

1. What is Drilling Riser?

2. Types of Drilling Risers

2.1. Marine Drilling Risers

2.2. Tie-back Drilling Risers

What is Drilling Riser?

Drilling risers are a pipe that connects an offshore oil well to the associated drilling platform. A riser runs up starting from the seabed up to the drilling platform. It is a large diameter pipe or series of interconnected pipes designed to withstand high pressures, extreme temperatures and extreme loads. The primary purpose of drilling riser is to transfer drilling fluid from seabed up to the drilling platform. It is a conduit and provides pathway to drilling fluid.

Types of Drilling Risers

Based on the whether the wellhead and Blow Out Preventer (BOP) are located on the seabed or on the drilling platform, the associated riser can be classified in following two types.

Marine Drilling Risers

In these types of offshore risers, blow out preventers (BOP) are located on the seabed. A blow out preventer is a safety device used to control the flow fluid from oil well.

- This type of drilling risers are larger in diameter to accommodate the flow of fluid from the seabed to the drilling vessel.

- These offshore risers consist of low pressure main tubes along with auxiliary lines which carry high pressure choke and kill lines for the blowout preventer located on the seabed. These auxiliaries also carry power and control lines for BOP.

- These risers are generally used by floating drilling vessels.

If the subsea oil well is located below a depth of 20 meters, normally the marine riser has to be tensioned using a riser tensioner which maintains constant tension along the riser to maintain stability. A tension riser prevents the motion of the riser along with waves. Tension force should be optimum for stability and the magnitude of this tension force is determined based on weight of riser equipment including weight of internal fluids, buoyancy of the riser, forces from waves etc.

This makes design of marine drilling risers, a complex job involving significant amount of engineering. ISO 12624-1:2009 provides guidelines for marine drilling riser design, selection, operating and maintenance.

Tie-back Drilling Risers

In these types of risers, blow out preventers (BOP) are located on the surface platform rather than the seabed. These types of risers are generally used for very stable platforms such as fixed platforms or spars. Hence they are also quite stable and their design does not require engineering analysis as extensive as for marine risers.

Since the blowout preventer is located on the drilling platform, a tie-back drilling riser contains various casings from the wellbore up to BOP located on the platform. These risers are a set of concentric pipes running from BOP to casing strings in the subsea wellbore.