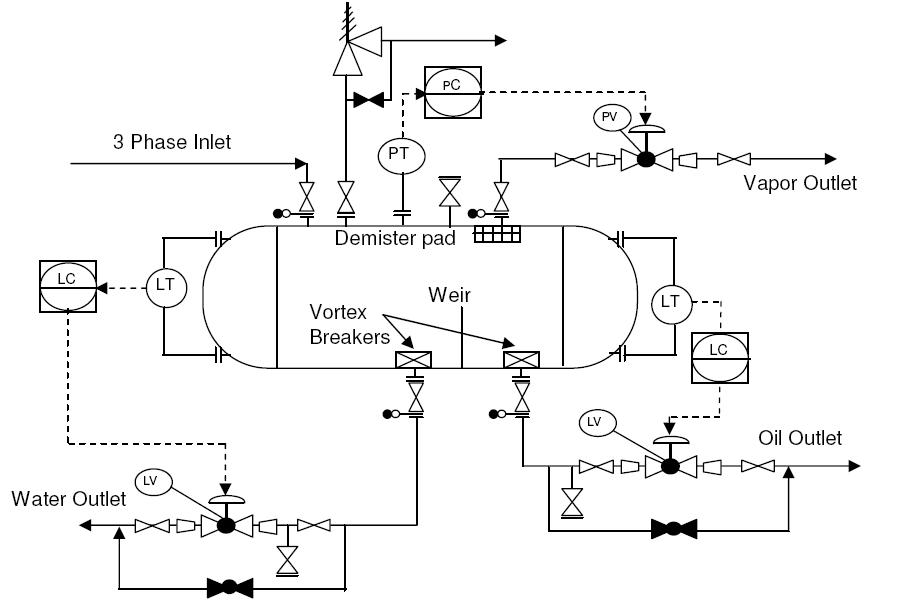

3 phase separator vessel P&ID diagrams are very important in the oil and gas industries. Because 3 phase separators are commonly used in the upstream oil and gas industry to separate oil, gas and water streams coming from the oil wells.

Table of content:

P&ID arrangement for 3 phase separator vessels

Guidelines for creating 3 phase separator P&ID

P&ID arrangement for 3 phase separator vessels

The diagram from above represents a typical P&ID for 3 phase separators. This typical 3 phase separator P&ID arrangement can be modified and used for other separator vessels as well.

Guidelines for creating a 3 phase separator P&ID

Selection of vessel symbol

The proper vessel symbol should be selected first of all, as shown in the presented drawing. This should be selected from the list of equipment symbols on the legend sheets of a particular project.

Vessel internals

Separator vessel internals should then be indicated as per proper symbols on the legend sheets. These internals can be an inlet vane, vortex breaker on the outlet lines, demister pads on gas outlets, weir plate separating the oil and water compartments, etc.

Demister is an internal device that removes any remaining mist or droplets from the gas stream before it exits the vessel. Demisters are important for reducing emissions and ensuring the gas stream is clean.

Inlet vanes are used to help control the flow of incoming fluids and improve separation efficiency. The inlet vane is typically located at the inlet nozzle of the vessel. It works by redirecting the incoming fluid to prevent turbulence and improve the distribution of the phases within the vessel.

Nozzles

All the nozzles on the separator vessel should then be correctly represented with size and flanges. This includes inlet and outlet nozzles, drains, vents, PSV connection, and instrument nozzles, as shown in the sample drawing presented here. Typical instrumentation on the vessel would be level gauges and transmitters on oil and water compartments of the vessel plus pressure gauge and transmitters linked to pressure control or alarms as applicable.

Inlet / Outlet lines

Inlet and outlet lines are the next to be drawn up. Line number, material class, size, etc. is to be correctly assigned to each of the lines.

Inlet and outlet lines are an important component of the P&ID arrangement for a 3-phase separator vessel. The inlet line is the pipe or conduit that delivers the incoming fluid mixture to the separator, while the outlet lines carry the separated gas, oil, and water phases out of the vessel.

Isolation valves, spectacle blinds, spacers

Isolation valves, spectacle blinds, spacers, etc. to be used for maintenance should be drawn up next on the inlet/outlet lines. The spectacle blinds, spacers, etc. are usually connected right next to the isolation valves and equipment nozzles, as indicated in the sample drawing presented here.

Isolation valves are used to isolate the separator from the rest of the system for maintenance or repair purposes. Spectacle blinds are used to blind off a section of the piping, usually to allow for maintenance or inspection. Spacers are used to maintain a specific distance between components, such as valves or instruments.

Instrumentation

The instrumentation on the vessel should be drawn up next. Typically this would include level gauges, level transmitters, pressure gauges, and pressure transmitters as per requirement for control, alarm, and trip if applicable. The sample drawing presented here only indicates transmitters, but generally, they are accompanied by gauges for local indication and also transmitters for alarms and trips.

Control valves

Various control valves should be drawn up next wherever applicable. Sample drawing indicates level control on oil and water outlet lines. Plus pressure control is indicated on the vapor outlet to flare. These control valves should be equipped with either a bypass or handwheel as per project standards, to continue vessel operation in case of control valve maintenance.

Vents & Drains

Drains should be provided either on the vessel or on the bottom outlet lines for complete draining of the vessel and associated piping for maintenance purpose. The sample drawing has indicated drains on the outlet lines through which the vessel and piping can be completely drained. Usually, the vessel also has nozzles connecting it directly to the draining system.

Vents can be present either on the vessel itself or on the vapor outlet line so that the vessel and associated piping can be completely vented for maintenance. A vent connected directly to the vessel is indicated in the sample drawing.

Blanketing connection

In most cases, the vessel is provided with a blanketing gas connection. This blanketing connection can be with or without pressure control. Although not indicated in the sample drawing, it is important to consider the blanketing gas connection to the vessel.

It is used to provide a means of introducing an inert gas into the vessel to prevent flammable or explosive mixtures from forming in the vapor space above the liquid level.

Utility connection

For purging the vessel with nitrogen, a connection can be provided directly on the vessel. In some cases, purging can be done with steam.

All the guidelines given here are very general and may be modified as per specific requirements of any particular project.