What is Pump Overloading ?

Centrifugal pumps are said to be overloaded when the driving motor draws excess current resulting in excess then normal power consumption. This overloading of the pumps can negatively affect pump operation and life of the centrifugal pumps. Following sections discuss these effects of pump overloading and how they can be prevented.

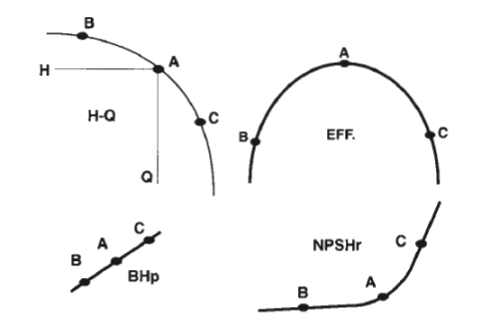

Avoid operating the pump at zone “C” as :-

The flow is high and the head (pressure) is low on the H-Q curve. This pump is operating with reduced efficiency, this time to the right of the best efficiency point (BEP) (point A in figure -1). Power consumption is higher at point C (right of the BEP on pump performance curves) and may overload the installed motor. The NPSHr has rises to the point of pump being strangled; the liquid leaves the pump faster than it can come into the pump. The pumped liquid is prone to vaporize or boil when operated at point C (right of the BEP on pump performance curves).

Damage caused due to overloading of pumps

When pump is operated in a zone around point C, following problems can occur.

- This is the zone where classic vaporization cavitation occurs.

- The shaft is under a deflection load. The shaft that is deflected rotates on its own center line even though the center line may not be straight. This produces a reversal of stresses in the shaft in each revolution that could lead to fatigue cracking and an eventual breakage of shaft.

- Failure of the mechanical seal and bearings.

- Higher power consumption.

- Higher vibrations.

- Radial loading (about 240” from the cutwater), resulting in shaft deflection.

To counteract these results, the operator should restrict the control valve on the pump’s discharge to reduce the flow.

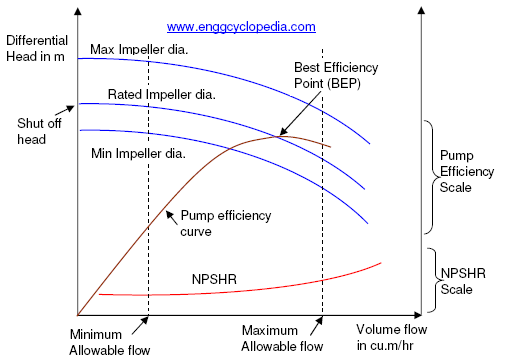

Following figure-2 shows a sample pump performance curve along with the pump best effecincy point (BEP).