Gasifier equipment is generally classified as upward draft, downward draft and cross draft gasifiers, based on the direction of air/oxygen flow in the equipment. It should be noted that there are types of gasifier equipment which are different from types of gasification processes. Gasification processes can be categorized into three groups: entrained flow, fluidised bed and moving bed (sometimes called, somewhat erroneously, fixed bed).

Four Gasifier Types

In a gasifier, fuel interacts with air or oxygen and steam. So the gasifier are classified as per the way air or oxygen is introduced in it. On a bigger scale there are following four gasifier types.

The choice of the one type of gasifier over the other is mostly determined by the fuel, its final available form, its size, moisture content and ash content. First three type of gasifiers are mostly used in entrained bed gasification process and moving bed gasification process. While the last one is fluidised bed gasification process.

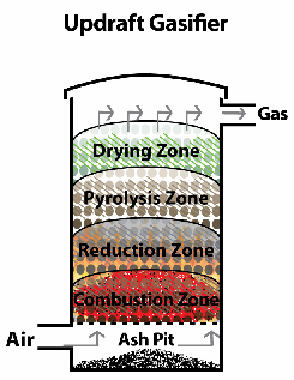

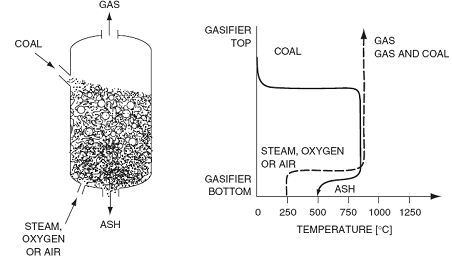

Upward Draft or Counter-Current gasifier

This one is oldest and simplest of all gasifier types. The air comes in at the bottom and produced syn gas leaves from the top of the gasifier. Near the grate at the bottom combustion reaction occurs, above that reduction reaction occurs. In the upper part of the gasifier heating and pyrolysis of the feedstock occurs as a result of heat transfer by forced convention and radiation from the lower zones. Tars and volatile produce produced during the reaction will leave along with the syn gas at the top of the gasifier. Which will be later separated by use of cyclone and candle filter.

The major advantages of this type of gasifier are its simplicity, high charcoal burn out and internal heat exchange leading to low temperature of exit gas and high equipment efficiency. This gasifier can work with several kind of feedstock ranging from Coal to Biomass.

Major drawbacks result from the possibility of "channelling" in the equipment, which can lead to oxygen break-through and dangerous, explosive situations and the necessity to install automatic moving grate.

Inlet of coal can be decided based on the type of gasification process selected to be used in this gasifier.

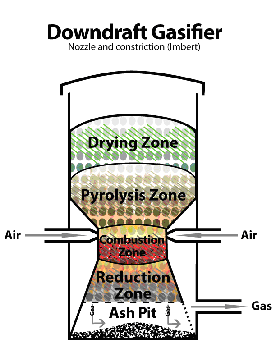

Downdraft or Co-Current Gasifier

In updraft gasifier there is a problem of tar entrainment in the product gas leaving stream. A solution is to have primary gasification air introduced at or above the oxidation zone in the gasifier. The produced gas is taken out from the bottom hence fuel and gas move in the same direction.

On their way down, the acid and tarry distillation products from the fuel must pass through a glowing bed of charcoal and therefore are converted into permanent gases hydrogen, carbon dioxide, carbon monoxide and methane. Depending on the temperature of the hot zone and the residence time of the tarry vapours. More or less a complete breakdown of the tars is achieved.

Main advantage of downdraft gasifier lies in the possibility of producing tar free gas for engine operation. However in practice very rarely tar free gas is produced but the % of tar leaving in product stream is considerably lower than leaving through the updraft gasifier.

Main disadvantage is that downdraft gasifier cannot be operated with range of different feedstocks. Low density feedstock gives rise to flow problems and excessive pressure drop. High ash content coal also gives more problem with this kind of gasifier than updraft gasifier.

Other disadvantage is it gives lower efficiency, since there is no provision internal exchange compare to updraft gasifier. The product stream also has low calorific value.

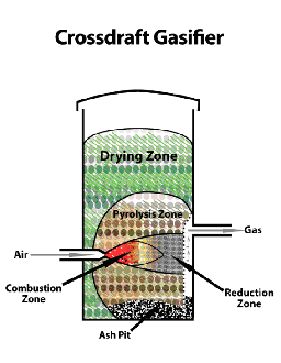

Cross Draft Gasifier

Although cross draft gasifiers have certain advantages over updraft and downdraft gasifiers, they are not ideal. The disadvantages such as high exit gas temperature, poor CO2 reduction and high gas velocity are the consequences of the design. Unlike downdraft and updraft gasifiers, the ash bin, fire and reduction zones in cross draft gasifiers are separate. These design characteristics limit what kind of fuel can be used, restricting it to only low ash fuels such as wood, charcoal and coke. The load following ability of cross draft gasifier is quite good due to concentrated zones which operate at temperatures up to 12000C. Start up time (5-10 minutes) is much faster than that of downdraft and updraft units. The relatively higher temperature in cross draft gas producer has an obvious effect on exit gas composition such as high carbon monoxide and low hydrogen and methane content when dry fuel such as charcoal is used. Cross draft gasifier operates well on dry air blast and dry fuel.

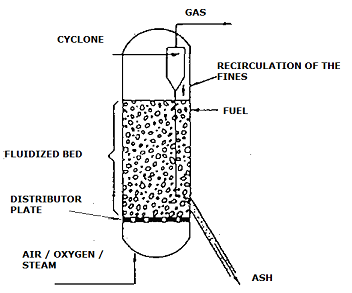

Fluidized Bed Gasifier

The operation of both up and downward draft gasifiers is influenced by the morphological, physical and chemical properties of the fuel. Problems commonly encountered are: lack of bunkerflow, slagging and extreme pressure drop over the gasifier.

A new design to address all this difficulties is fluidised bed gasifier.

Air is blown through a bed of solid particles at a sufficient velocity to keep these in a state of suspension. The bed is originally externally heated and the feedstock is introduced as soon as a sufficiently high temperature is reached. The fuel particles are introduced at the bottom of the reactor, very quickly mixed with the bed material and almost instantaneously heated up to the bed temperature. As a result of this treatment the fuel is pyrolysed very fast, resulting in a component mix with a relatively large amount of gaseous materials. Further gasification and tar-conversion reactions occur in the gas phase. Ash particles are also carried over the top of the reactor and have to be removed from the gas stream if the gas is used in engine applications. To remove ash particles cyclone and candle filter are used.

The major advantage of fluidised bed is processing of feedstock. This type of gasifier are mostly used for high ash coal and biomass. Since temperature is below the ash softening temperature so handling of ash is relatively simple.

Drawback of fluidized bed gasifiers is - high tar content in the produced syn gas and incomplete carbon conversion.