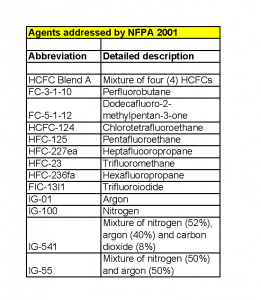

Clean agents addressed by NFPA 2001 are electrically non-conducting substances which do not leave any residue upon evaporation.

Clean agents are generally divided into two (2) groups: halocarbon agents and inert gases (IG).

A typical table of the clean agents covered by NFPA is given below. Of course, it is to be noted that the list of clean agents provided below is indicative. Other mediums could become available in the near future and be eligible for inclusion in this list, taking into consideration that as per NFPA 2001, all agents included or proposed to be included in this standard shall first undergo a strict evaluation process similar to the process used by the U.S. Environmental Protection Agency’s (EPA) SNAP Program.

Limitations on use of clean agents for fire fighting

Clean agents shall not be used for extinguishing fires involving the following materials:

- certain chemicals, like cellulose nitrate, gunpowder, organic peroxides, hydrazine etc

- reactive metals such as lithium, sodium, potassium, magnesium, titanium, zirconium, uranium and plutonium,

- metal hydrides.

Consideration needs to be given to clean agents deterioration in hazards with high operating temperatures (ovens, furnaces etc). Whenever a total flooding system is used, a fixed enclosure is to be installed around the hazard in order to allow a specified agent concentration to be achieved and maintained for a specific time duration.

All necessary safety measures like pre-discharge alarm, time delay, warning signs, Self Contained Breathing Apparatus (SCBA), training etc shall be implimented.

NOAEL (No Observed Adverse Effect Level) as well as LOAEL (Lowest Observable Adverse Effect Level) values for each substance shall also be considered. Indicative information for these levels is given at Table 1.5.1.2.1(a) of NFPA 2001.

Depending on the concentration of each clean agent (% v/v), NFPA 2001 stipulates maximum allowable human exposure limits, ranging from some seconds to the maximum value of 5 minutes. The smaller the agent concentration, the bigger the maximum allowable human exposure limit.

Components of clean agent based fire protection systems

The quantity of primary agent supply shall be at least sufficient for the largest single hazard protected or group of hazards to be protected simultaneously. The exact quantity of reserve agent supply is to be decided by the Authority Having Jurisdiction.

Clean agents will have to meet some very specific quality standards referring to their purity, acidity, water content and non-volatile residue, in accordance with Tables 4.2.1(a), 4.2.1(b) and 4.2.1(c) of NFPA 2001.

Agents shall be stored in containers designed to hold that specific agent at ambient temperatures.

Containers used for these systems, if not shipping containers, shall be designed, certified and stamped in accordance with Section VIII of the ASME Boiler and Pressure Vessel Code. The design pressure shall be suitable for the maximum pressure developed at 130°F (55°C) or at the maximum controlled temperature limit.

Selection of total flooding quantity

Calculation of the exact quantity of clean agent necessary largely depends on the type of fire. Minimum design concentration is calculated after multiplying the flame extinguishing (or inerting) concentration with a safety factor. Flame extinguishing (or inerting) concentration is mostly calculated through different types of tests and experiments.

The minimum value of safety factor stipulated by NFPA 2001 is 1.2 for Class A and Class C fires, whereas for Class B fires, safety factor gets a value of 1.3.

Halocarbon clean agents for fire fighting

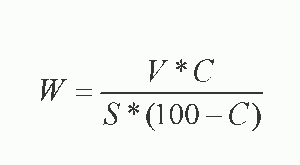

The total amount of halocarbon agent required to achieve the design concentration is calculated using the formula below:

Formula for calculation of halocarbon agent total flooding quantity

where:

W = the weight of the clean agent (in kg)

V = the net volume of the hazard (in cubic meters)

S = the specific volume of the superheated agent vapor at 1 atmosphere (in cubic meters/kg)

C = the agent design concentration (volume percent)

t = the minimum estimated temperature of the protected volume

Total flooding quantities based on this equation are given in Tables A.5.5.1(a) through Table A.5.5.1(r) of NFPA 2001.

Inert gases for firefighting

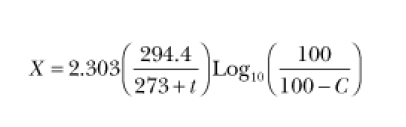

In case we don't have a halocarbon agent but an inert gas agent, i.e. IG-01, IG-100, IG-541 and IG-55, then the design concentration is calculated using the formula below from NFPA 2001.

Calculation formula for inert gases design concentration

where:

X = the volume of inert gas added at standard conditions of 1.013 bar and 21 degrees Celsius per volume of hazard space

t = minimum estimated temperature of protected volume in degrees Celsius

Corresponding total flooding quantities for these inert gases agents are given at Tables A.5.5.2(a) through Table A.5.5.2(h) of NFPA 2001.

More detailed information on the design of other components, like piping, fittings, valves, nozzles, alarm-actuation devices etc can be found by studying in more detail NFPA 2001.