Syngas

Syngas is a mixture of Carbon Monoxide and Hydrogen which is the product of steam or oxygen gasification of organic material such as biomass. After clean up, syngas can be used to produce organic molecules such as synthetic natural gas (SNG-methane (CH4)) or liquid biofuel such as synthetic diesel. Syngas is the term generally used for mixture of combustible gases. So typically a syngas mixture will constitute of only hydrogen and carbon monoxide, with possibility of having carbon dioxide content sometimes. If the gasification product contains significant amount of non-combustible gases such as nitrogen and carbon dioxide, the term used for such mixtures is 'Producer Gas'.

Producer Gas

Producer gas is a mixture of combustible (Hydrogen, Methane and Carbon Monoxide) and non-combustible (Nitrogen, Carbon dioxide) gases. The heating value of producer gas varies from 4.5 to 6 MJ/m3 depending upon its constituents. Similar to syngas, producer gas is also produced by gasification of carbonaceous material such as coal or biomass. When atmospheric air is used as gasification agent, the producer gas consist mostly of carbon monoxide, hydrogen, nitrogen, carbon dioxide and methane.

| Carbon monoxide | 18-22 % |

| Hydrogen | 13-19 % |

| Methane | 1-5 % |

| Heavier hydrocarbons | 0.2-0.4 % |

| Carbon dioxide | 9-12 % |

| Nitrogen | 45-55 % |

| Water vapour | 4 % |

Table 1 - Typical composition of producer gas

Water Gas

Actually a mixture of only Carbon Monoxide and hydrogen is called water gas. Water gas is generally used for production of hydrogen. Since both constituents of water gas are combustible gases, they can be used as input to gas turbine for power production. Water gas shift reaction (Lowe's gas Process) CO+H2O → CO2+H2 is used to remove carbon monoxide from water gas to get pure hydrogen for the fuel cell applications. Water gas shift reaction is very sensitive to temperature and increasing temperature reverses the direction of the reaction. This process also known as Lowe's Gas Process is often done in two stages one at high temperature shift 3500C and another at low temperature shift 190-2100C. Industrial catalyst for this reaction is iron oxide promoted with chromium oxide for the high temperature shift and copper mixed with zinc oxide and aluminum oxide for low temperature shift.

Carbon monoxide is produced from reduction of carbon dioxide and it is generally 18-22% on volume basis. Its octane number is 106 but its burning velocity is low. It is very toxic in nature.

Hydrogen is also the product of reduction process in gasification. Its octane number is in the range of 60-66 but its burning velocity is very high. Hence it increases the burning velocity of producer gases. Methane and hydrogen are mostly responsible for high heating value of the gases. Nitrogen and carbon dioxide are non combustible gases in the producer gases. High percentage of carbon dioxide indicates incomplete reduction inside the gasifier.

Applications of Syngas

- Syngas is used as an intermediate in the industrial synthesis of hydrogen and ammonia.

- Syngas has 50% of the energy density of natural gas.

- It can be burnt and is used as a fuel source.

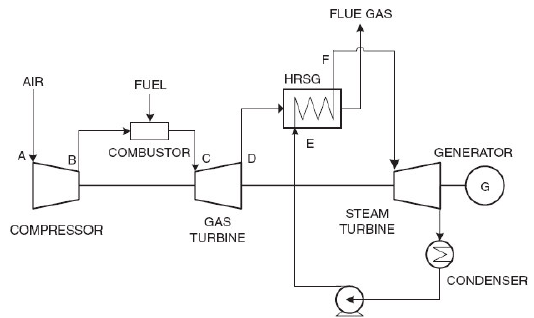

- Syngas is used as a fuel in power generation using IGCC power plant.

Applications of Producer Gas

- Producer gas can fuel hot-air generators of the kind used to produce hot air in industries such as those involved with production of fertilizer and cement.

- Producer gas can also be used for heating water in a number of industrial applications.

- Another benefit of producer gas is its suitability for melting of glass in the production of artifacts.

- In addition, producer gas can be employed in food processing industry to provide heat for drying vegetables, seeds and to heat ovens in bakeries.

Applications of water Gas

- Water gas consists of combustible carbon monoxide and hydrogen and hence can be used as a feed to gas turbines in power generation.

- Primarily water gas is used for hydrogen production using water gas shift reaction also known as Lowe's Process. Water gas shift reaction (Lowe's gas Process) CO+H2O → CO2+H2 is used to remove carbon monoxide from water gas to get pure hydrogen for the fuel cell applications. Water gas shift reaction is very sensitive to temperature and increasing temperature reverses the direction of the reaction. Lowe's Gas Process is often done in two stages one at high temperature shift 3500C and another at low temperature shift 190-2100C. Industrial catalyst for this reaction is iron oxide promoted with chromium oxide for the high temperature shift and copper mixed with zinc oxide and aluminum oxide for low temperature shift.