Steps in Combined Cycle Power Plant

Various steps in combined cycle power plant are the following

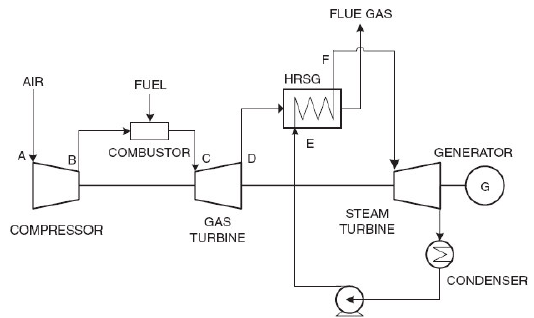

- Atmospheric air (A) is compressed in compressor and pressurized air (B) enters into the GT combustor where it mixes with fuel and undergoes combustion.

- The resulting very high temperature gases (C) enter into gas turbine.

- The exhaust gases (D) from gas turbine have temperature of around 500 - 5500C. Heat recovery steam generator (HRSG) generates steam using water (E) by utilizing exhaust gases and finally, flue gases from HRSG are sent to stack.

- The generated steam (F) drives steam turbine and exhaust from steam turbine is fed to the condenser. Condensed water is again pumped back to the HRSG.

Schematic of the operation of combined cycle power plant

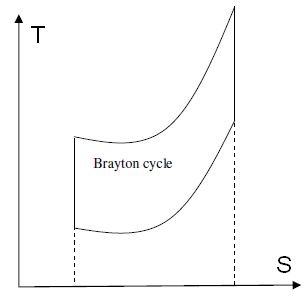

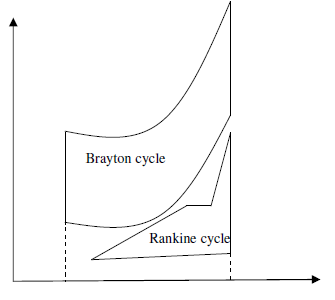

T-S plot for the Bryton cycle and combined cycle power plant are shown in figure .The ratio between the area enclosed by cycle and area below the upper line in the cycle is called overall efficiency. Open cycle gas turbine has efficiencies of around 43 %. Because of the Rankine cycle present below the Brayton cycle, combined cycle has efficiencies of around 60 %.

Fuel for a combined cycle plant is either natural gas or light petroleum distillates. Resources for these fuels are limited, so, cost of these fuels is increasing continuously. To get the full advantage of combined cycle, extensive work has been done to find out other possible feed stocks for GT. Gasification products of heavy oils and coals seem to be a viable option for this. Use of coal gasification products in gas turbine has gained much interest in recent years, because of the quantity of coal reserves available throughout the world.