Electrostatic precipitators (ESPs) are industrial emissions control units that are typically installed at coal power plants. Their purpose is to collect and remove dust particles from the exhaust flue gas of a power plant at a typical efficiency level of 99.9% or more.

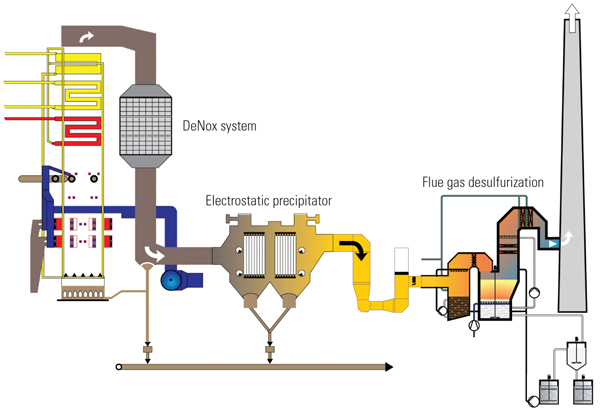

They are installed upstream power plant stack, usually between DeNOx system (a system whose purpose is to reduce NOx emissions) and flue gas desulphurisation (FGD) system (a system whose purpose is to reduce SOx emissions).

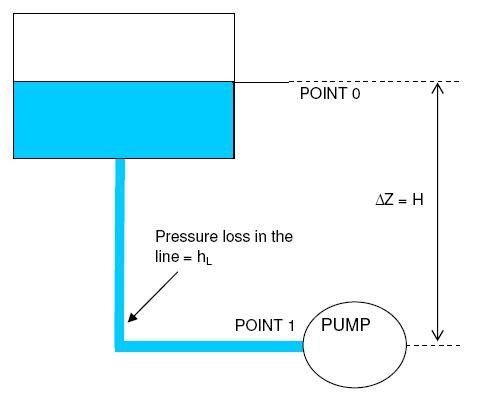

Figure 1 - Typical layout of an electrostatic precipitator

How electrostatic precipitators work

Electrostatic precipitators work by placing a positive charge on a group of plates installed at the exhaust gas stream. As flue gas enters electrostatic precipitator system, an electrode at the electrostatic precipitator inlet applies a negative charge on the flue gas stream particles. The opposite polarity acts like a magnet, extracting the particles (ash) from the gas steam and attaching them to the plates. Collected ash is removed by the plates by various methods, causing the ash to fall into hoppers installed below electrostatic precipitators. Through a conveyor system, dislodged ash is subsequently send for recycling or disposal.

Byproducts of Electrostatic Precipitators

Fly ash and bottom ash are typical byproducts of electrostatic precipitators. Both of them are powdery materials (bottom ash is generally larger in size compared to fly ash), very abrasive and corrosive, which can be profitably recycled and constitute a significant revenue for the utility or the Independent Power Producer (IPP).

Typical use of bottom ash are in cold mix emulsified asphalt mixes as well as raw feed material for portland cement.

Fly ash can be used in structural fill, in land development, building materials, highway construction, metals recovery, manufacturing of agricultural fertilizers etc.