Pipeline pigging is a maintenance operation used in the oil and gas industry to clean, inspect, and maintain pipelines using a device called a pig. A pipeline pig, is a cylindrical object that is inserted into the pipeline and then forced through it by the flow of fluid.

It moves through the pipeline, scraping or brushing the internal surfaces to remove debris, scale, corrosion, and other contaminants that can accumulate over time. It can also be used to inspect the pipeline for cracks or other damage. Pigging is a safe and effective way to maintain pipelines and ensure that they are operating properly.

Table of Content:

1. Basics of pigging

2. Pig Traps (pig receivers and pig launchers)

3. Pipe Pig Types

4. Pipeline Pigging Procedure

5. Typical P&ID arrangement for pig launchers and receivers

Basics of pigging

Pigging is a method of cleaning and inspecting pipelines. It involves the use of a device called a pig, which is a device that is inserted into a pipeline and propelled by the flow of product or by a separate propelling mechanism. It moves through the pipeline, scraping or brushing the internal surfaces to remove debris, scale, corrosion, and other contaminants that can accumulate over time.

Pigging is a safe and effective way to maintain pipelines and ensure that they are operating properly. Check basics of pigging in the given post.

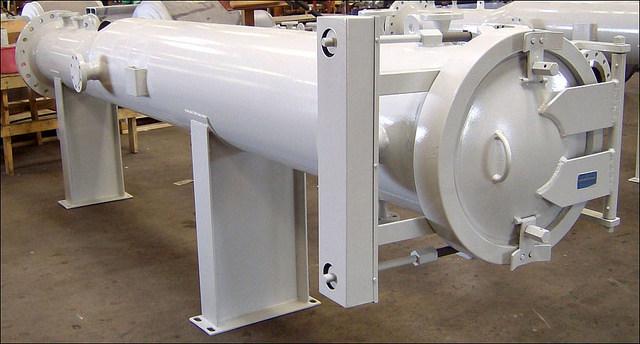

Pig Traps (pig receivers and pig launchers)

Pig traps (pig receivers, and pig launchers) are devices used in pipeline pigging to safely and effectively transport pigs through pipelines. They help to prevent pigs from getting lost or damaged, and they improve the efficiency of the pigging process.

Pipe Pig Types

There are several types of pipe pigs, each designed for a specific purpose. The type of pig to be used and its optimum configuration for a particular task depends on the purpose of pigging, contents in the pipeline, and characteristics of the pipeline such as size, minimum bend radius, types of valves etc. Based on these factors a type of pig tool is chosen. Check detailed discussion on types of pipe pigs in the given post.

Pipeline Pigging Procedure

Check the given post to study Hazards involved in the pigging operations, precautions to be taken during pigging and typical step by step procedure for pigging. The procedures to be followed at pig launcher end and at pig receiver end are also discussed.

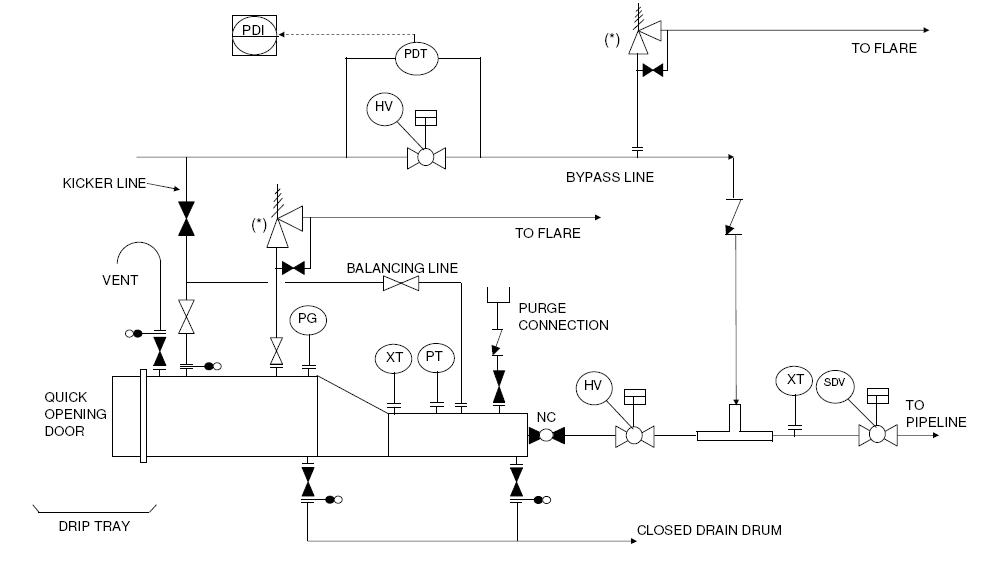

Typical P&ID arrangement for pig launchers and receivers

Typical P&ID arrangement for pig launchers and pig receivers used for oil pipelines is shown including the requirements for isolating, draining/venting and bypassing the pig traps. Other requirements such as balancing/kicker lines, purging connections, motorized valves, relief valves are also presented.