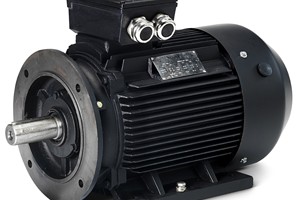

Perhaps the most well-known type of electric motor in use nowadays is the three-phase squirrel cage induction motor.

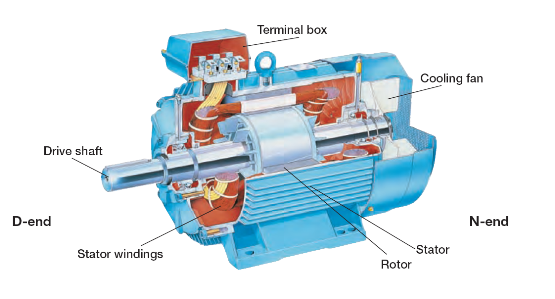

It typically consists of two (2) main components: the stator and the rotor. As their name implies, the stator part is stationary, whereas the rotor part is rotating. The stator produces the rotating magnetic field compared to the rotor, which transforms this type of energy into movement, i.e. mechanical energy. Please refer to Figure 1 (D-end stands for motor driven end, i.e the equipment driven by the motor, e.g. a pump, is located at that side, whereas N-end stands for motor non-driven end)

How an electric motor works

To explain how an electric motor operates, one must first note that the stator is connected to the three-phase power supply. The current which is applied at the stator windings produces a rotating magnetic force field, which by its turn creates current also at the rotor of the motor. As a result, a magnetic field is also created at the rotor. The interaction between these two magnetic fields (i.e. from the stator and from the rotor) yields the turning torque, which is the cause that makes the rotor shaft rotate.

Motor rotation speed and motor slip

Due to various losses inherent to the motor's nature, the speed of the motor is always approximately 1 to 3 % lower compared to the magnetic field synchronous speed. This difference is usually referred to as motor slip (s).

Slip is given by the following formula:

s = (n1 - n) / n1.... (1), where:

n1=synchronous speed

n= asynchronous speed

As a result, this type of motors is usually known as asynchronous motors.

However, it is to be noted that permanent magnet motors do not produce any slip at all (permanent magnet motors will not be discussed at this article)

The synchronous speed (n), expressed in revolutions per minute (or rpm) is given by the following formula:

n = (120 * f)/ p .... (2), where:

f = motor supply frequency (in Hz) and

p = number of motor poles (even number)

Electric motor efficiency

As expected, the energy conversion at a squirrel cage induction motor is not loss-free. Several losses occur, being among others the result of resistance losses, ventilation losses, friction losses etc.

Consequently, the motor efficiency (n) is expressed from the following formula:

n = P2 / P1 .... (3),where

P2 = motor shaft power (in W)

P1 = applied electric power (in W)

P2 is mentioned at the motor's name plate.

Insulation class

Insulation class refers to the insulation material of the motor's windings. Several insulation classes, namely B, F and H, exist, in accordance with IEC (International Electrotechnical Commission) standards. A letter corresponding to the temperature, which is the upper limit for the insulation application area, characterizes each insulation class.

Insulation class B corresponds to a maximum winding temperature of 130°C (ambient temperature 40°C + temperature increase 80°C + temperature margin 10°C)

Insulation class F corresponds to a maximum winding temperature of 155°C (ambient temperature 40°C + temperature increase 105°C + temperature margin 10°C)

Insulation class H corresponds to a maximum winding temperature of 180°C (ambient temperature 40°C + temperature increase 125°C + temperature margin 15°C)

Protection class

A motor's protection class is stated with the letters IP (IP stands for Ingress Protection) followed by two digits, the first of which indicates the degree of protection against contact and penetration of solid objects, whereas the second states the motor’s degree of protection against water. This classification is in accordance with IEC 60034-5 standard. For more details about IP protection designation, please refer to Enggyclopedia article about the "Ingress Protection Enclosures".

Cooling method

Cooling methods is accordance with IEC 60034-6 can tell how a squirrel cage induction motor is cooled. The cooling method is designated with the letters IC (IC stands for International Cooling) followed by a series of digits, representing the cooling type (e.g. self-ventilated, forced cooling etc) and the cooling mode of operation (e.g. surface cooling, liquid cooling etc). Please refer to Figure 2, highlighting the most common methods of squirrel cage induction motor cooling.