A canned pump is a type of centrifugal pump that features a unique construction where the motor and impeller are enclosed in a metal can. The can separates the pumped fluid from the motor, which prevents the fluid from coming into contact with the motor and causing damage.

This makes it suitable for handling hazardous or corrosive fluids. Additionally, canned pumps offer several benefits such as improved efficiency, reduced maintenance costs, and increased safety, which makes them popular in various industries including chemical processing, petroleum, and power generation.

Table of content:

Construction of canned pumps

Operation of canned pumps

Advantages of the seal less canned motor pumps

Construction of canned pumps

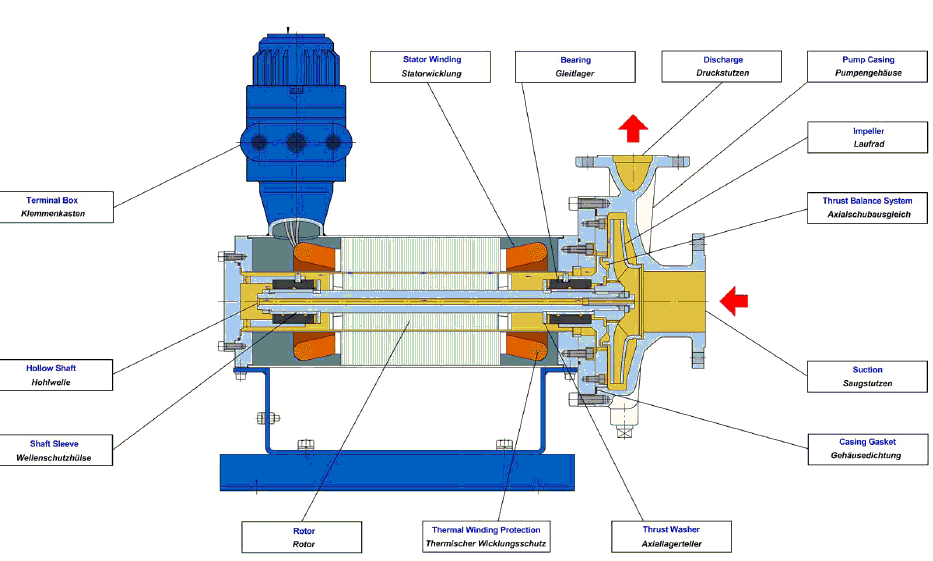

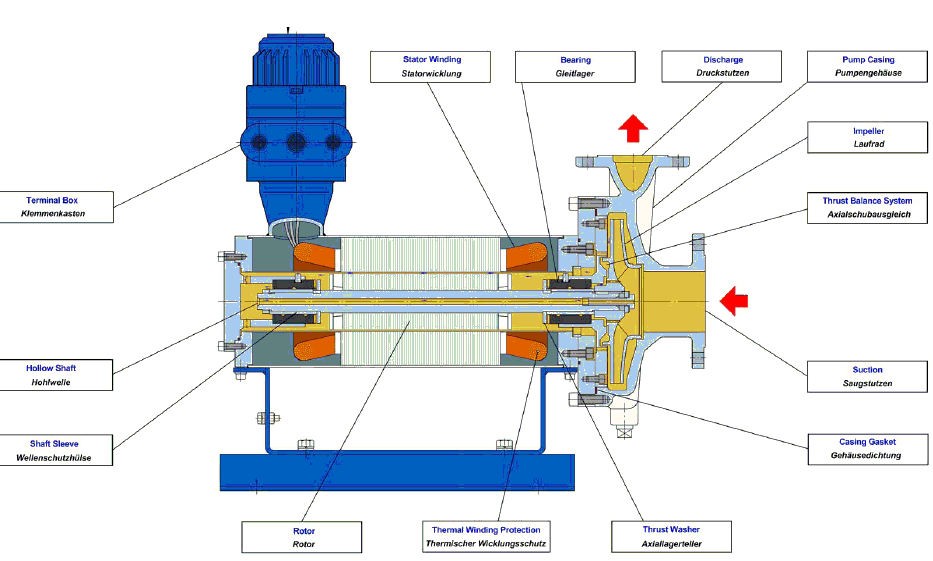

![]() The construction of a canned pump typically consists of three main parts: the can, the motor, and the impeller. The can is usually made of a sturdy metal such as stainless steel, and it encloses the motor and the impeller. The can is designed to withstand high pressure and temperature conditions, as well as corrosive or hazardous fluids.

The construction of a canned pump typically consists of three main parts: the can, the motor, and the impeller. The can is usually made of a sturdy metal such as stainless steel, and it encloses the motor and the impeller. The can is designed to withstand high pressure and temperature conditions, as well as corrosive or hazardous fluids.

The motor is mounted inside the can and is designed to drive the impeller. The motor is typically a sealed unit that is completely enclosed and separated from the fluid being pumped. This helps protect the motor from damage and ensures that the fluid is handled safely.

The impeller is a rotating disc with vanes that is responsible for moving the fluid through the pump. The impeller is mounted on the motor shaft and is located inside the can, where it rotates at high speeds to create centrifugal force that moves the fluid through the pump.

Overall, the construction of a canned pump is designed to provide a safe and efficient way to move fluids, while protecting the motor from damage and ensuring that the fluid being pumped is handled safely.

Operation of canned pumps

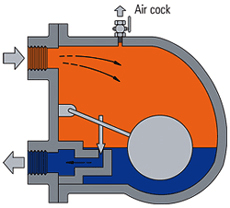

The operation of a canned pump involves the can and impeller working together to move fluid through the pump. Here is a step-by-step explanation of how it works:

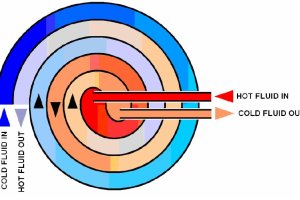

- The fluid enters the pump through the inlet and flows into the space between the can and the impeller.

- As the impeller rotates, it creates centrifugal force that moves the fluid from the center of the impeller to the outer edges.

- The fluid is then pushed out of the impeller and into the discharge outlet, where it can be transported to its destination.

- The can separates the motor from the fluid being pumped, preventing the fluid from coming into contact with the motor and causing damage.

- The motor drives the impeller, providing the rotational energy needed to move the fluid through the pump.

The can and impeller work together to create centrifugal force that moves the fluid through the pump, while keeping the motor separated from the fluid being pumped.

Check this post to study typical procedure to start canned motor pump.

Advantages of the seal less canned motor pumps

Canned pumps are important in various industries for several reasons. They offer improved safety by preventing the pumped fluid from coming into contact with the motor. This is especially important when handling hazardous or corrosive fluids, as it can prevent damage to the motor and ensure that the fluid is handled safely.

Let’s look at the advantages of a canned pump design that features a double seal barrier, no mechanical seal, and a one-piece design.

- Double seal barrier: A double seal barrier ensures that the pump is 100% leak-proof, which is important for preventing hazardous fluids from leaking into the environment.

- No mechanical seal: A canned pump with no mechanical seal has a higher mean time between failures (MTBF) because there is no seal that can wear out or fail. This reduces maintenance costs and downtime.

- Low maintenance costs: Canned pumps with no mechanical seals or complex lubrication and cooling systems require less maintenance. This reduces maintenance costs and downtime.

- One-piece design: The one-piece design of the canned pump saves space, as it eliminates the need for ancillary equipment, such as cooling systems. This can be particularly beneficial in applications where space is limited.

- Low sound level: Canned pumps have a smooth operation with low noise and vibration. This reduces the risk of damage to equipment and enhances safety for personnel.

- Easy assembly and disassembly: Canned pumps are easy to assemble and disassemble, which reduces downtime and maintenance costs.

- No clamping tie-rod: The absence of a clamping tie-rod enhances safety in case of fire. Because it eliminates the risk of the pump being damaged or becoming a hazard during a fire.

- Complete flushing: The pump can be flushed through the flushing hole without disassembling the pump. This simplifies maintenance and results in decreased downtime.

- Hydraulic balancing: The hydraulic balancing of the axial thrusts ensures a smooth operation and reduces wear and tear on the pump components.

- Automatic degassing: Automatic degassing ensures that any air bubbles in the fluid are removed, which enhances pump efficiency and reliability.

- Stator liner not submitted to traction efforts: The stator liner is not submitted to traction efforts created by pressure or differential dilatations. This reduces wear and tear and enhances the lifespan of the pump.

- Effective cooling: The intense circulation of the liquid in the motor allows for effective cooling, which enhances pump efficiency and reliability.