Pressure relief valves are essential devices for ensuring safety and integrity of the vessels handling fluids. These valves prevent equipment failure by removing excess pressure build up from the system. Maximum Allowable Working Pressure (MAWP) refers to the maximum pressure at which a vessel, equipment, or system is designed to operate safely during normal operating conditions.

To ensure effective operation, it is essential to understand the concept of MAWP. This post explores details of Maximum Allowable Working Pressure along with the difference between MAWP and design pressure.

Table of content:

1. What is Maximum Allowable Working Pressure?

2. Importance of MAWP

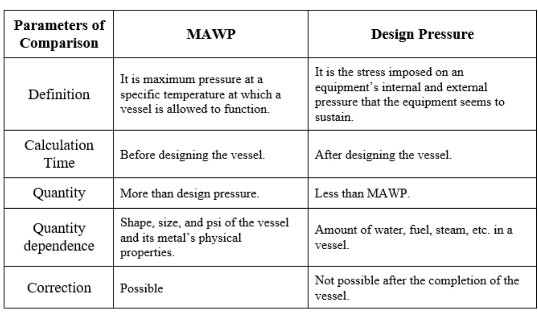

3. Design Pressure vs MAWP

What is Maximum Allowable Working Pressure?

The maximum allowable working pressure is the highest pressure that the vessel can withstand based on actual nominal vessel thickness excluding the allowances provided for corrosion and loadings other than pressure. MAWP refers to the highest pressure at which a relief valve can operate safely under normal conditions.

MAWP has to be at the least equal to design pressure. MAWP is commonly calculated for a fabricated vessel. During fabrication, availability of materials and thickness of material used usually leads to a vessel exceeds the minimum requirements imposed by design pressure. For such a vessel the MAWP is greater than design pressure. For a vessel which only meets the minimum requirements imposed by design pressure, MAWP is equal to the design pressure.

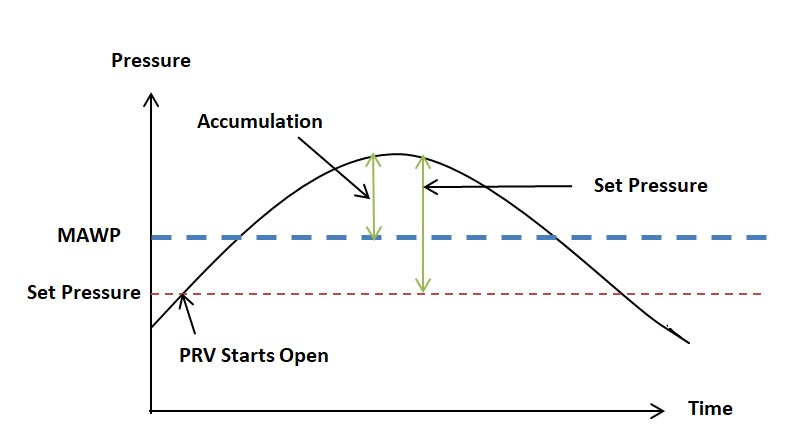

MAWP can be used in two ways. First it defines limit of the maximum pressure under which the valve is designed to operate efficiently. Another use is that it acts as a reference point for set pressure or valve's opening.

Various industrial facilities worldwide consider the value of the maximum allowable working pressure (MAWP) when establishing safety rules and protocols to ensure the safety of their staff and products. The MAWP of a vessel always exceeds its maximum allowable operating pressure (MAOP) and design pressure.

MAWP depends on various factors such as the thickness of the vessel and the mechanical design. It also depends on the physical properties and conditions of the vessel, such as corrosion and fatigue. The MAWP of any vessel is always higher than its or MAOP and the design pressure. While calculating MAWP the shape, size, and psi of the vessel and its metal’s physical properties are also checked.

Importance of MAWP

Valves operating above the MAWP can lead to a range of risks and consequences. This can result in catastrophic failure of equipment. That's why proper selection of MAWP is crucial for safety and integrity of the vessel and system.

Valve Failure: Relief valves are designed and engineered to operate within specific pressure ranges. When the pressure exceeds the MAWP, it can exert excessive stress on the valve components. This can potentially lead to valve failure.

Leakage: Operation of relief valve above MAWP may result in seal failure or damage to valve seat, Which result in leakage. Leakage can lead to release of hazardous materials into environment and can cause hazard.

Safety Hazards: Exceeding MAWP can result in equipment rupture, explosions or release of hazardous fluid to environment. This can lead to hazardous condition. The overpressure conditions can result in the release of hazardous materials or the failure of other interconnected equipment or piping systems.

Design Pressure vs MAWP

The main difference between MAWP and design pressure is that the design pressure is always calculated while designing the equipment, whereas MAWP is measured after completing it.