Pressure relief valves are mechanical devices used for protecting systems from overpressure by releasing excess pressure in critical conditions. Thus relief valves prevent the system from catastrophic failure and save it from hazards that may potentially result in equipment damage and harm to personnel.

That's why pressure relief valves or safety valves are one of the most important components in process industries to maintain the safety and integrity of the process. This post explores the details of pressure relief valves. This post also contains resources related to the types, design and maintenance of pressure relief valves.

Table of content:

1. What is pressure relief valve?

2. How pressure relief valves work?

3. Types of pressure relief valves

4. Pressure relief valve sizing

5. Key terminology for relief devices on vessels

6. Difference between Safety Valve and Relief Valve

7. Pressure Safety Valve (PSV) Testing

8. Valve Interlock System

9. Safety valves change over valves

10. API standards for pressure relieving systems

11. Typical Safety Relief Valve Datasheet

12. Safety Valves P&ID Symbols

13. Pressure Safety Valves – Typical P&ID arrangement

14. Tank Venting

15. Pressure Vacuum Relief Valves (PVRV)

16. Rupture disc

What is pressure relief valve?

In process industries, equipment such as vessels, tanks, or pipelines face conditions of overpressure due to various reasons. If pressure is not relieved from the system in an overpressure condition, equipment may explode and can cause severe damage. So, it becomes very important to relieve excess pressure from equipment at the correct time to prevent major hazards.

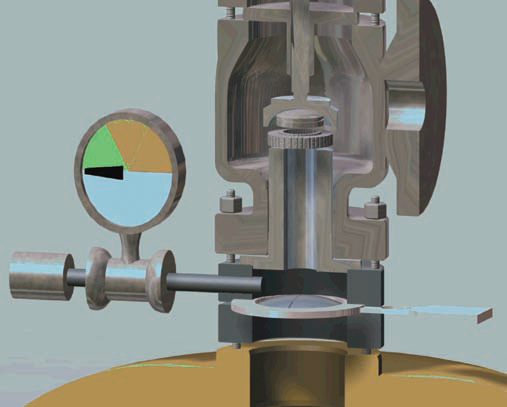

Pressure relief valves are designed to automatically open in the overpressure condition of the equipment. By automatically opening, these components relieve excess pressure from the system and prevent the system from potential damage caused by overpressure.

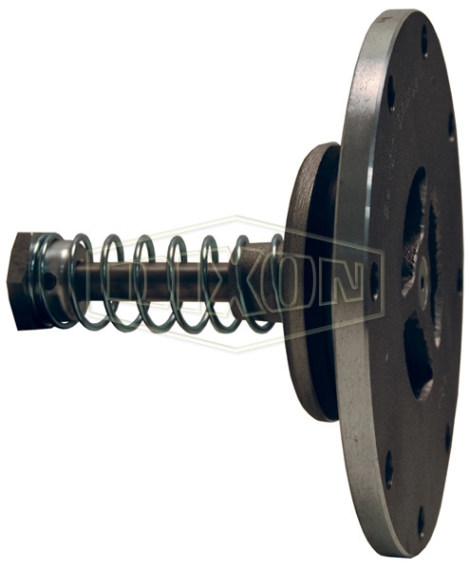

Once the pressure drops below the setpoint, the force exerted by the spring becomes greater than the pressure force. This causes the valve to close. The valve remains closed until the pressure rises again and exceeds the setpoint.

The major difference between control valves and pressure relief valves is that the other valves control the flow of fluids or gases within a system while pressure relief valves focus on managing pressure levels.

Pressure relief valves are used in different types of process industries such as oil and gas, chemical processing, power generation, and manufacturing often incorporate pressure relief valves to protect equipment and processes against overpressure scenarios.

How pressure relief valves work?

There are types of mechanisms used for relieving excess pressure from the system. The most common mechanism use spring loaded valve that remain closed under normal operating conditions. The spring applies force to close the valve under normal conditions.

Pressure relief valves continuously monitor the pressure within a system. When the pressure rises and reaches the setpoint, it overcomes the force exerted by the spring. This force imbalance lifts the valve and opens the pathway for excess fluid to escape and relieves excess pressure immediately.

Types of pressure relief valves

Check this post to explore some common terms of pressure relief valves and different types of pressure relief valves.

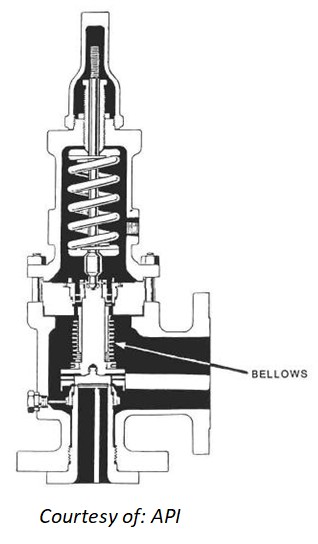

- Balanced bellows relief valve

- Conventional pressure relief valves (PRVs)

- Pilot operated relief valve

- Power actuated pressure relief valve

- Vacuum relief valve

Pressure relief valve sizing

Safety valves are designed by analyzing the concerned equipment, and related fluid service, then simulating the overpressure scenario to finally perform pressure safety valve sizing calculations. This post discusses various overpressure scenarios and pressure relief valve sizing calculations for some of those cases.

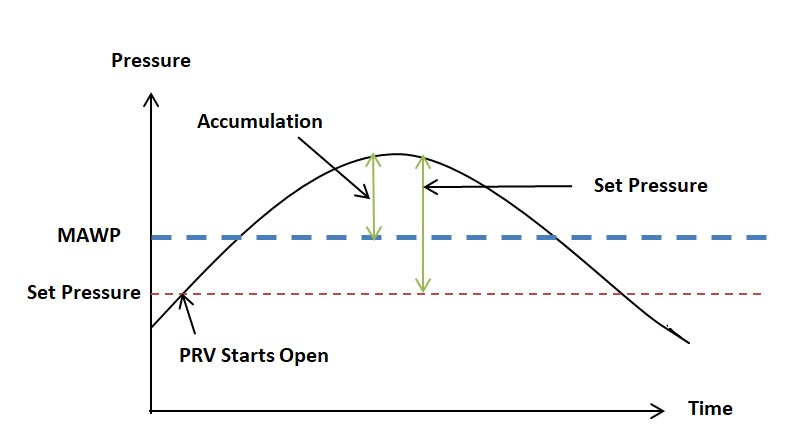

Key terminology for relief devices on vessels

This post discusses key terminology for relief devices that help better understand the design and usage of these pressure relief devices.

Difference between Safety Valve and Relief Valve

'Pressure Safety Valve' and 'Pressure Relief Valve' are commonly used terms to identify pressure relief devices on a vessel. Frequently these terms are used interchangeably and it may entirely depend on a particular project or company standards to identify all the pressure relief devices either as 'safety valves' or as 'relief valves' or sometimes even as 'safety relief valves'. Although freely used interchangeably, these terms differ in the some aspects. This post outlines the key differences between pressure relief valves and pressure safety valves.

Pressure Safety Valve (PSV) Testing

Testing of PSVs (or PRVs) is done to ensure that the valve can open properly when set pressure is reached in the protected vessel. Also to ensure that desired relieving rate is achieved and valve can close properly after the pressure drops. PSV testing can be done either in "in-situ" manner or by doing bench testing. Check this post to explore need for Pressure safety valve testing along with the types of it.

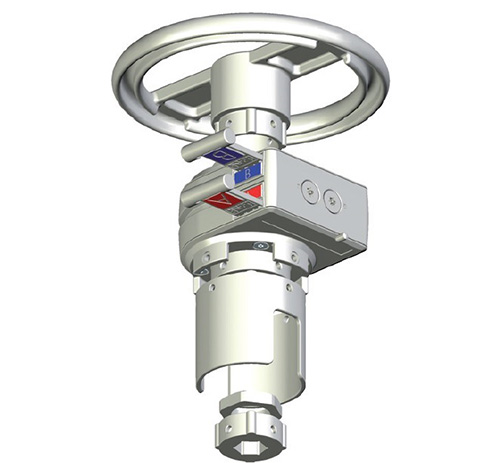

Valve Interlock System

Valve interlock system is a safety mechanism used in industries to ensure proper sequence of valve operation. Valve interlock system is used to prevent unintended operation of valve that could lead to catastrophic failure. By using valve interlock we can ensure correct opening and closing of safety valves.

Safety valves change over valves

- Change-over valves are used to connect two safety valves to a pipe system with the use of only one pipe joint. In such a case, one safety valve is is operation and the other one is on stand-by (redundant). The stand-by valve can be removed for maintenance reasons while in operation, while the entire pressure system is kept protected from overpressure.

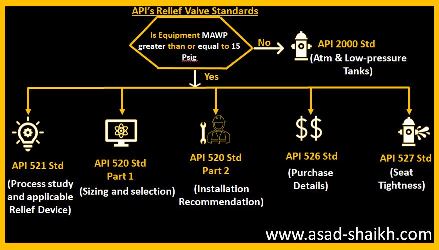

API standards for pressure relieving systems

The given post contains list of API standards, codes, recommended practices etc. for design, selection, installation and inspection of pressure relieving systems in refineries, petrochemical facilities, natural gas facilities and for venting requirements of equipment within such facilities.

Typical Safety Relief Valve Datasheet

When ordering a safety relief valve, the user has to provide the Manufacturer with a specification sheet (datasheet) that specifies all necessary information for that relief valve. Check this post to see items contained in the datasheet of a safety relief valve.

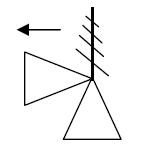

Safety Valves P&ID Symbols

It is very important to know about different types of safety valves and their P&ID symbols, especially for process engineers. Because safety valves are important components in process industries to protect equipment and personnel from overpressure situations.

This post contains commonly used P&ID symbols (Piping and Instrumentation Diagram symbols) for safety valves. Note that they may differ slightly from one project to another.

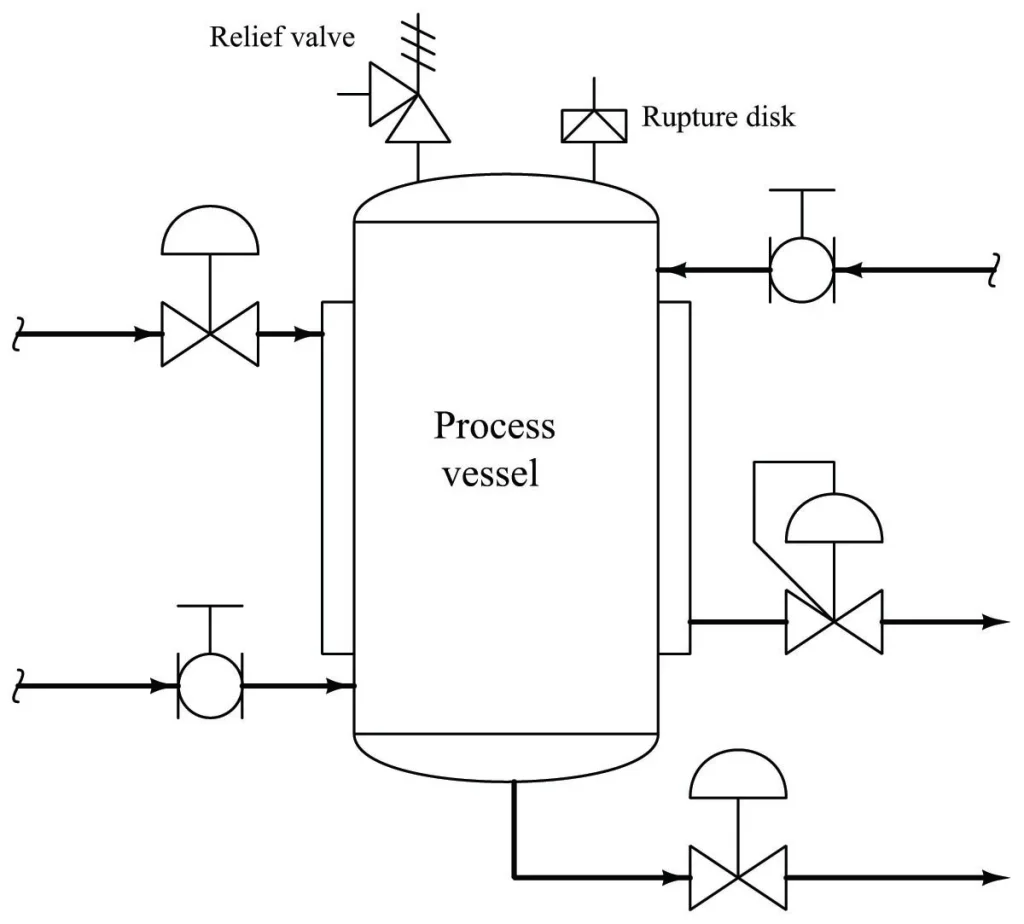

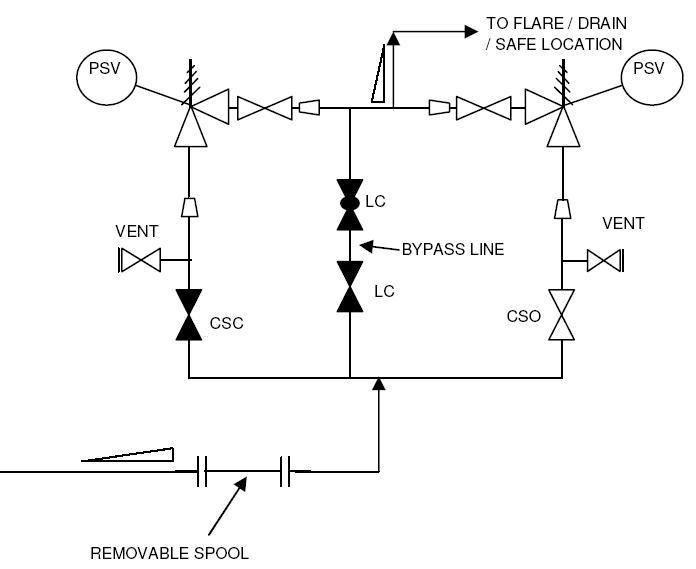

Pressure Safety Valves – Typical P&ID arrangement

It is very important to understand the pressure safety valves P&ID arrangement. Because safety valve is one of the most important part in process system.

The sample drawing presented in the given post represents a typical arrangement generally used to represent pressure safety valves or relief valves on P&ID.

Tank Venting

For low pressure or atmospheric storage tanks and process vessels, the design pressure is also low. The tanks are designed to work at near atmospheric pressures. Hence any increase or decrease in the operating pressure needs to be mitigated when it occurs. Overpressure is often mitigated by tank venting. Check details of tank venting in the given post.

Venting Calculation – Inbreathing

It is desirable to protect low pressure equipment operating at near atmospheric pressure (1.013 bara), against vacuum. This is done by providing a venting arrangement for inbreathing of air to eliminate vacuum. Methodology to calculate the requirement of inbreathing flow of air is discussed in this article.

Venting Calculation – Outbreathing

It is desirable to maintain some low pressure equipment at near atmospheric pressure (1.013 bara). This is done by providing a venting arrangement for outbreathing of gas to protect against overpressure. Methodology to calculate the outbreathing flow of gas is discussed in this article.

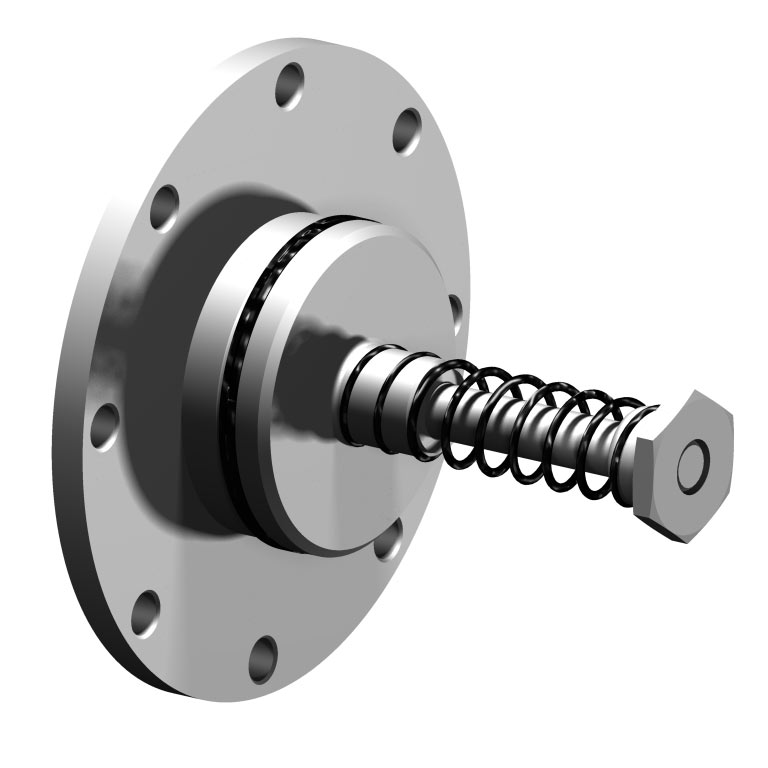

Pressure Vacuum Relief Valves (PVRV)

The pressure/vacuum relief valve is a protection device which is typically installed on a flanged nozzle installed at the top of a fixed roof atmospheric storage tank. These valves perform the dual function of protecting the tank against overpressure by releasing the gas inside the tank or 'outbreathing' and against vacuum by air intake from the atmosphere or 'inbreathing'.

Rupture disc

Rupture disc serves as crucial component in safeguarding pressure containing systems such as pressure vessels, storage tanks, reactors etc. Rupture discs are non reclosing devices. These devices are designed to burst or rupture at predetermined set pressure. By bursting or rupturing these devices relieve excess pressure and prevent system from catastrophic failure. This post explores rupture discs in detail. Also check when and why rupture discs should be combined with pressure safety valves.