Pumps suction specific speed is sometimes confused with pump specific speed parameter.

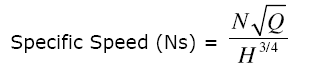

Pump Specific Speed Definition

Specific speed (Ns) is a term typically used to describe the geometry (shape) of a pump impeller.

where

N = the speed of the pump in revolutions per minute (rpm)

Q = the flow rate in liters per second or gallons per minute (gpm)

H = the total dynamic head in meters or in feet

Both flow rate and total dynamic head are calculated at the Best Efficiency Point (BEP) on the maximum available impeller diameter for the pump in question.

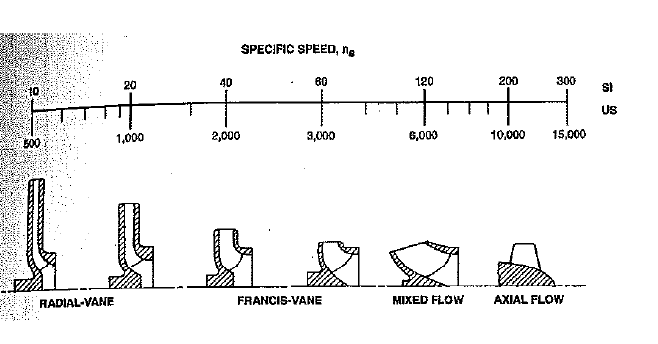

Picture 1 - Typical flow classification of pump impellers as per specific speed

Generally speaking, as the number of specific speed increases, the size of the impeller goes from radial vane shape (for values between 500 and 1,000 in the US scale) to axial flow shape (for values between 10,000 and 20,000 in the US scale). Impellers towards the right side are more efficient than those near the left side.

Pumps for high head, low capacity usually occupy the range between 500 to 1,000 (US scale). On the other hand, low head, high capacity pumps may have a specific speed of 15,000 or even bigger (US scale). In general, whenever we are faced with a specific speed value between 500 and 15,000, we know that such a pump exists and can be purchased from various pump suppliers.

For a given head and capacity, the pump meeting the requirements and having the highest specific speed will most often be the smallest size and the least expensive. However, the disadvantage is that the pump will operate at the highest speed where abrasive wear and cavitation damage start to become an issue.

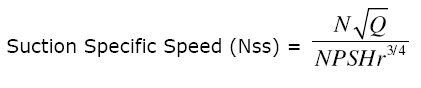

Pump Suction Specific Speed

On the other hand, suction specific speed is defined as follows:

where

N = the speed of the pump in revolutions per minute (rpm)

Q = the flow rate in liters per second

NPSHr = Net Positive Suction Head required

Similar to specific speed, both the flowate and NPSHr are calculated at the Best Efficiency Point (BEP) on the maximum available impeller diameter for the pump in question. The NPSHr (required NPSH) value is normally provided by the pump manufacturer.

Pump designers usually aim for highest possible efficiency, thus high suction specific speed. However, such designs may become problematic because the higher the suction specific speed, the closer the point is for troublesome pump internal flow recirculation.

As a rule of thumb, a value of 9,000 is a typical, reasonable and well-documented value for suction specific speed nowadays. However, pump user has to be aware that even a pump has a suction specific speed within this range, pump life expectancy is expected to be reduced if the pump is operated at flows much higher or lower than the BEP.

Summing up, selection of a pump is to be based taking into consideration multiple parameters (flow rate, head, NPSHavailable, NPSHrequired, pump efficiency etc).